2018

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

displacements are closer to each other, the two axial forces were

also close to the values of 35tons.

8 CONCLUSIONS

High correlation is recognized between the wall

displacements and the axial forces in the struts. In addition, the

changes of axial forces were negligible as the time elapses at the

locations where the large wall displacements are detected. This

means that the ground anchors are working quite well at such

locations (Jang et al., 2012).

In this study the displacement on the C.I.P. walls and the

axial forces on the slabs are monitored in the two excavation

sites. In the sites, two new top down methods, S.P.S & S.T.D,

are applied with the traditional support method, i.e. ground

anchor. The monitored values are analyzed and compared with

those predicted at the design stage. The conclusions obtained

are the following:

6.2 Site 2: S.T.D and C.I.P

1) The monitored displacements of C.I.P rigid walls with

S.P.S support were similar to the predicted values. The

displacement of the S.P.S support wall came from the

characteristics of the support which does not applies the

pre-stresses to the wall. The displacement of the wall is

allowed by the slab without restriction.

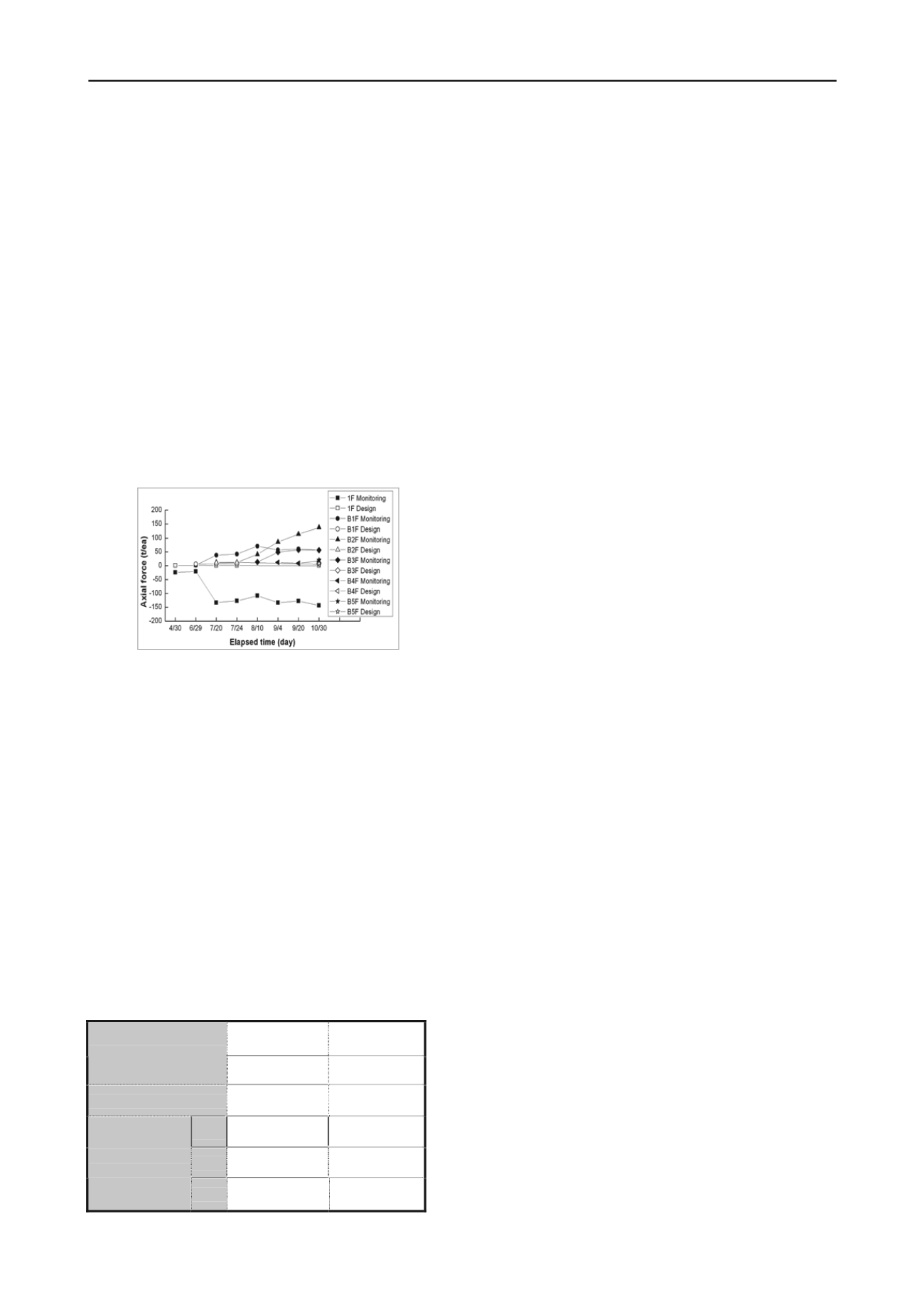

Fig. 14 shows the axial forces which act on the slab of S.T.D

method by comparing design and monitored values. The

monitored axial forces are mostly larger than the predicted

values set in the design stage. This result came from the

increased wall displacement due to over-excavation and the

characteristics of S.T.D. method.

Contrary to the direction of the soil pressures, tensile forces

are developed on the 1st anchor from the top. This may come

from the large displacement in the central part of the wall, i.e.

B2F and B3F, which gave reverse stresses on the upper part of

the wall.

2) Even though the rock layer is appeared in the shallow

depth, large displacements and axial forces are monitored

compared to the values predicted at the design stage in the

site where S.T.D. method is applied. This is because the

excavation depth is deep and the over-excavation was

made at the final stage of construction to reduce the

construction time.

3) It is necessary to reflect the characteristics of the

excavation method and the soil conditions when the

retaining walls are planned for excavation site. At the site

of excavation, the monitored value in each stage should be

reviewed and compared with the designed values.

Feedback analysis is sometimes needed when some field

problems are anticipated.

4) Quantitative inspection of the construction time of the

selected sites indentifies the significant reduction of the

construction time when the slab support methods are

applied compared with the traditional ground anchor

supports.

Figure 14. Section A-A’ Slab axial forces

7 COMPARISON OF CONSTRUCTION TIME

The current retaining wall design, which uses slab as the

support of the wall, applies S.P.S and S.T.D methods. These

methods can save the construction time because they can

support the retaining walls as well as can use the slabs as the

permanent basement structure of the building. The two sites

have different excavation area and depth. Hence a direct

comparison of the construction period was difficult. In this

study, construction period was calculated and relative

comparison was made based on the Site 1, which was quantified

by area (15,000 m2) and the excavation depth (GL.-19m).

9 ACKNOWLEDGEMENTS

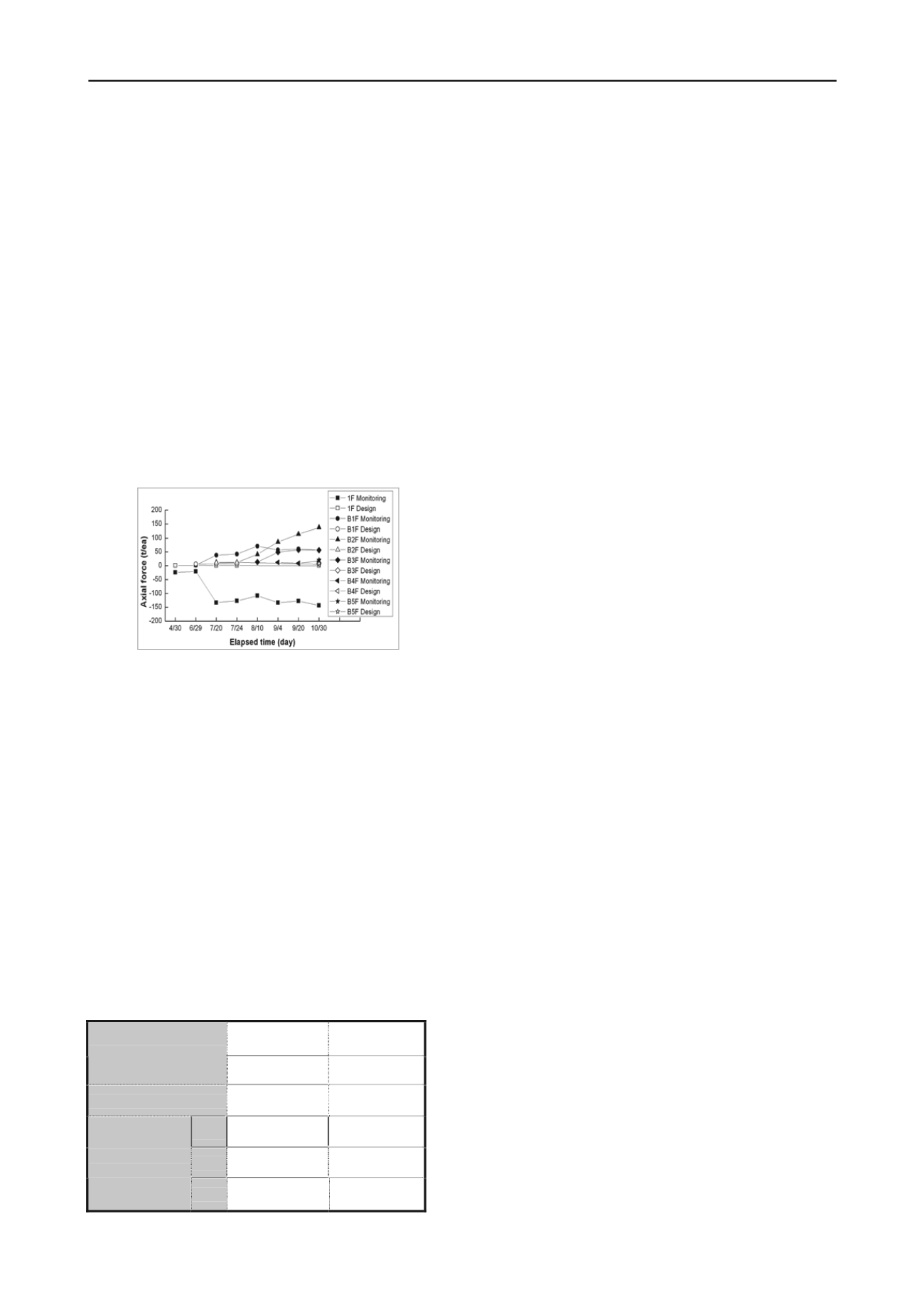

Table 1shows the comparison of the construction time of the

basement for different support methods. In Site 1 where the

ground anchors are partly used, the construction time was 9

months. However, in Site 2 where the slab support S.T.D is

used, the slabs are installed simultaneously with the excavation

and the time taken to finish the basement structure was 7

months.

This research was supported by the Basic Science Research

Program through the National Research Foundation of Korea

(NRF), funded by the Ministry of Education, Science and

Technology (No.2012-0002408). This paper is also a part of the

result from the “Maintenance of Foundation Design Criteria

under the Construction Facilities for Standardization”, the

“Construction & Transportation R&D Policy and Infrastructure

Project”.

10

REFERENCES

Geogroup Eng.(2010),"SUNEX Manual, 13th Ver. 6.01. SI Version",

P1-3.

Jang ,Y. S., S.M Shin and J.H. Hoe (2012), “A Study on Design and

Construction of Earth Retaining Wall Using Multi-Supporting

System”, KGS-IGS Geotechnical Workshop, I.I.T., New Delhi,

December 12.

Table 1. Comparison of construction time for two sites

Site 1: Chung Ju Site 2 : Sang Am

Construction Method

S.P.S & Anchor

S.T.D

Excavation Depth

GL.-19m

GL.-26m

Start

2010.10

2012.04

End

2011.06

2012.11

Excavation

And Sub- structure

Period

9 month

7 month

Saegil E&C (2011a), "Hyundai Department Chung Ju Excavation

Design and Field Monitoring Report"

Saegil E&C (2011b), "SANG-AM DMC E2-3BL Excavation Design

and Field Monitoring Report"

Sho, Kwang-Ho (2011) “Study on the Application of Semi-open cut

Top-Down Construction for Framework” Journal of the Korean

Association for Spatial Structures, Vol.11, No.2, pp.129~138.