2016

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3 SITE CONDITIONS

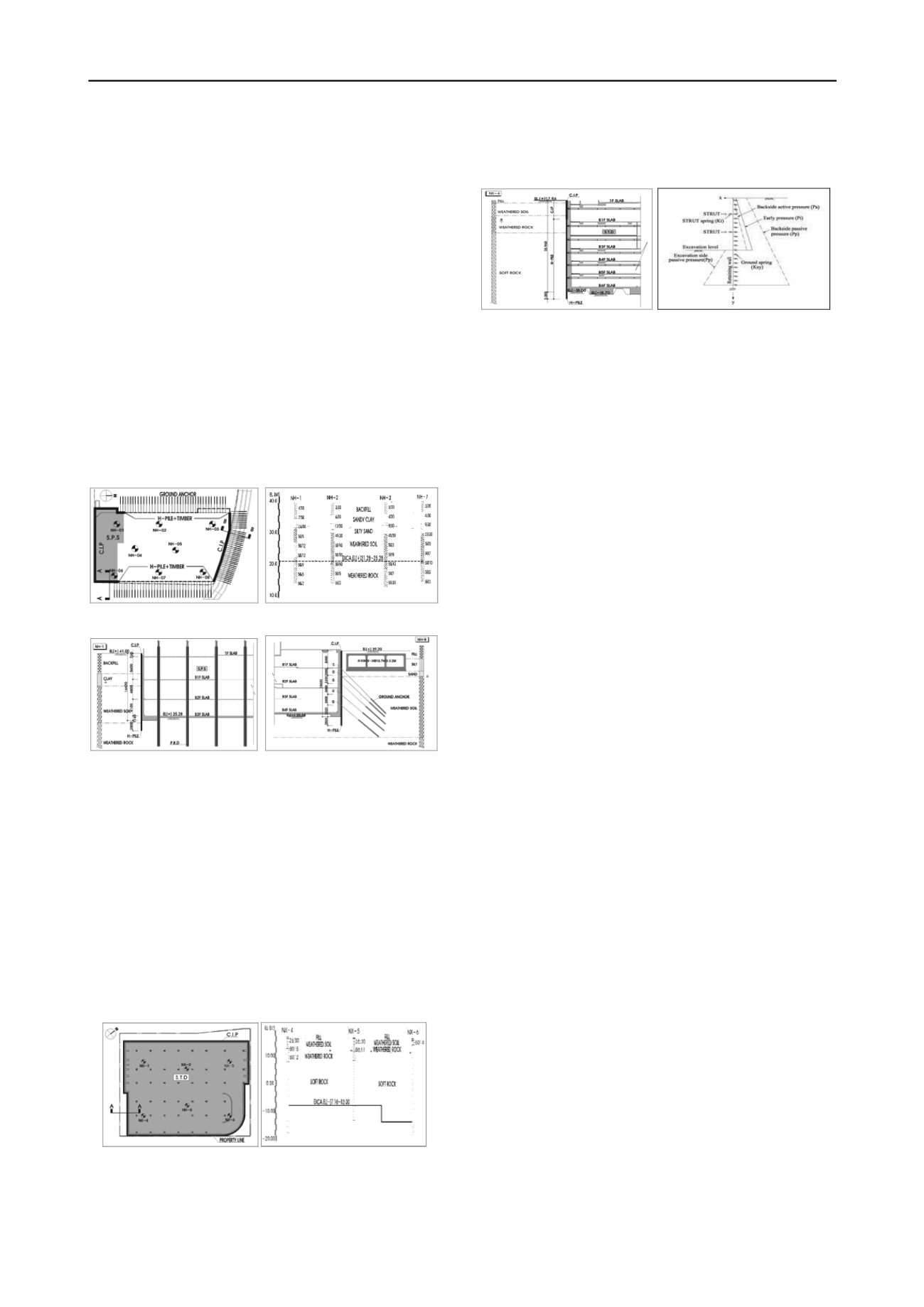

3.1 Site 1: S.P.S and ground anchor on C.I.P wall

Site 1 is the office facility of 7th floor on the ground and 3rd

floor in the basement. The building is located at Chung Ju in the

central region of Korea (Saegil E&C, 2011a). The excavation

depth is in the range of of GL.-14.0m~GL.-20.0m. High

apartments with deep parking lot are in the southern part of the

site. A building with basement is located 20m apart from the

site in the west. Roads of 35m and 23m are located at the north

and the east part of the site.

Two types of retaining walls are used, i.e. rigid C.I.P wall

and H-Pile & Timber. Ground anchor is used as the support of

both walls. Considering the tall buildings with basements, S.P.S

method is used at the southern part (Fig. 3).

The soil profile of the excavated site is composed of buried

soil layer, alluvial layer, weathered soil and rock layers from the

surface. Most of the excavated parts are composed of soils

(Fig.4). Two sections, i.e. S.P.S and ground anchor, are selected

as the analysis section in this paper (Fig. 5).

Figure 3. Plan view of site 1 Figure 4. Soil profile of site 1

a) Sec. A-A’ (C.I.P & S.P.S) b) Sec. B-B’ (C.I.P & Anchor)

Figure 5. Section view of Site 1

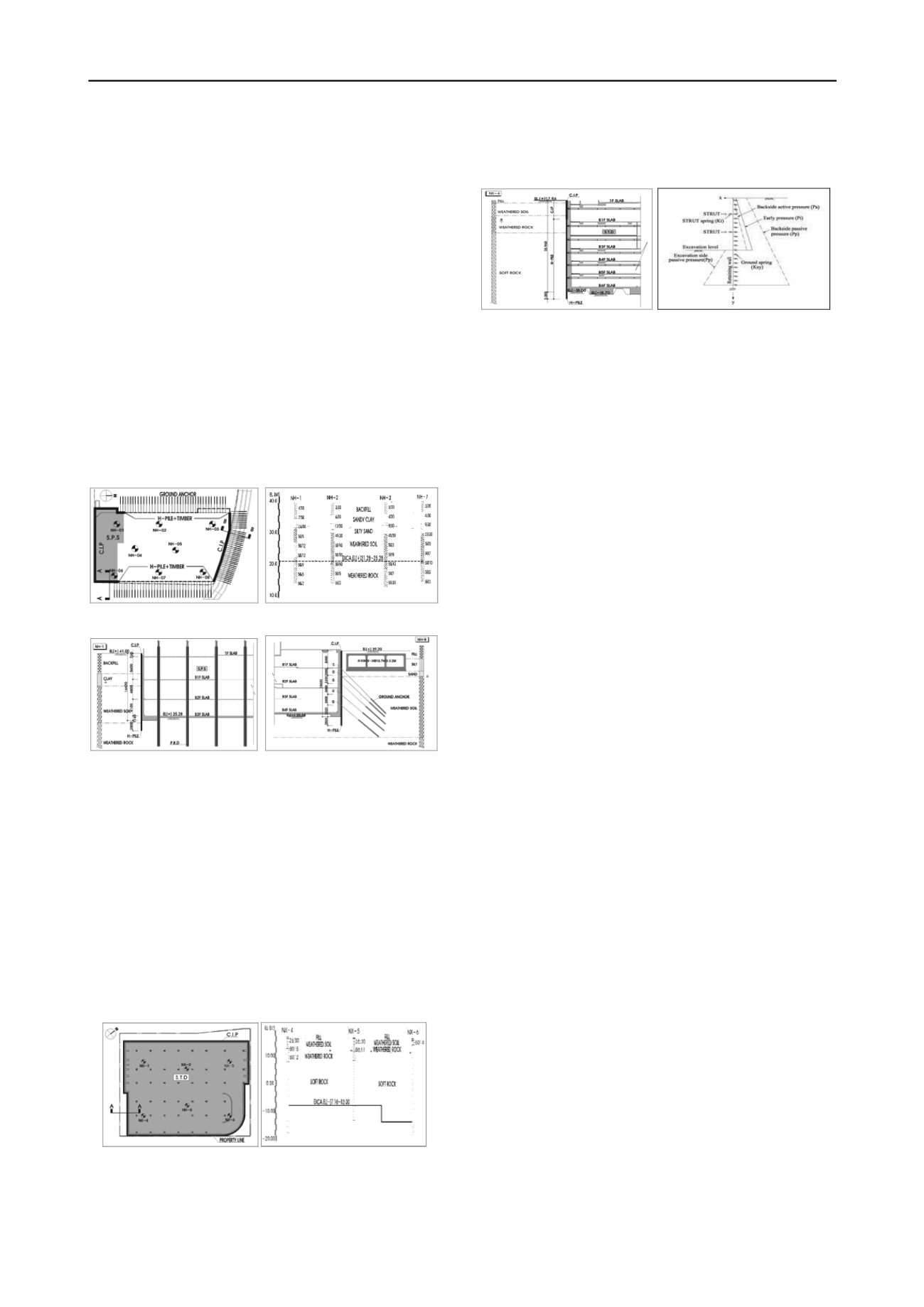

3.2 Site 2: S.T.D and C.I.P

Site 2 is the office facility of 23rd floor on the ground and 7th

floor in the basement. The building is located at Sang Am dong,

Seoul, Korea (Saegil E&C, 2011b). The excavation depth is in

the range of GL.-25.0m~GL.-31.0m. A building of 20th floor on

the ground and 5th floor in the basements is located to the north

of the site. In the east, the road of 30m wide and the building

with 21st floor on the ground and 7th floor in the basements is

located. The roads of 30m wide are located to the south and the

west directions.

The retaining wall is composed of C.I.P in the soil layer and

H-Pile & shotcrete in the rock layer. S.T.D method is used as

the support of the excavation site (Fig. 6).

Figure 6. Plan view of site 2 Figure 7. Soil profile of site 2

The soil profile of the excavated site is composed of buried

soil layer, weathered soil and rock layers, and soft rock layer

from the surface. The geotechnical investigation shows that the

soft rock appears at the shallow depth of GL.-2.4m and GL.-

9.2m (Fig. 7).

Figure 8. S.T.D Section A-A’ Figure 9. Schematic section for

Analysis Program

The sections of retaining walls, i.e. C.I.P in the soil layer and

H-Pile & shotcrete in the rock layer are selected for analysis.

S.T.D method is used as the supports of the excavated site (Fig.

8).

4 ANALYSIS PROGRAM FOR DESIGN

The program used in the design stage is SUNEX(Step UNder

ground EXcavation), which is a stress-strain analysis program

commonly used for the design of the deep excavation site in

Korea (Geogroup Eng., 2010). This program calculates earth

pressure on the braced earth retaining system, horizontal

displacement, shear force and bending moment of vertical wall

and axial force of supports and tieback anchors for step by step

excavation.

The program adopts elasto-plastic behavior of soil to

calculate earth pressure on the retaining wall. Calculation model

includes elastic beam for vertical wall (elastic-plastic beam

optional), elastic spring for strut and tieback anchor, elasto-

plastic spring for active and passive soil (Fig. 9).

5 COMPARISON OF DESIGN AND MONITORED

VALUES

Both the wall displacement and the axial stress of the struts

obtained either from the design stage using the SUNEX or from

the field monitoring using the field installed instruments. In this

section, The two values are compared by separating to the mid

and the final stage of the excavation.

5.1 Wall displacements

5.1.1 Site 1 : S.P.S and ground anchor on C.I.P wall

The displacements of wall in which S.P.S method is applied

are shown in Fig. 10 for the mid and final stages of excavation,

i.e. GL.-7.9m and GL.-16.5 m.

In the mid stage of excavation, the predicted design

displacement was 26.7mm and was greater about 20mm than

the monitored displacement of 7.0 mm. This discrepancy

seemed to come from the fact that the influence factors, e.g. the

loads behind the wall, the excavation height for installation of

supports, and weak soil profiles near the ground surface, were

selected conservatively compared with the real field conditions.

However, in the final stage the two values were come out

quite close. The reasons for this consistency are: (1) The

construction conditions was very similar to the one adopted in

the design stage, according to the construction process

identified at the site; (2) In S.P.S method, it is able to install the

steel supports immediately after the excavation. This gives an

advantage of reducing the time delayed displacement of the

wall, which developed the quite consistent displacements

between the design stage and the actual excavation.