2028

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

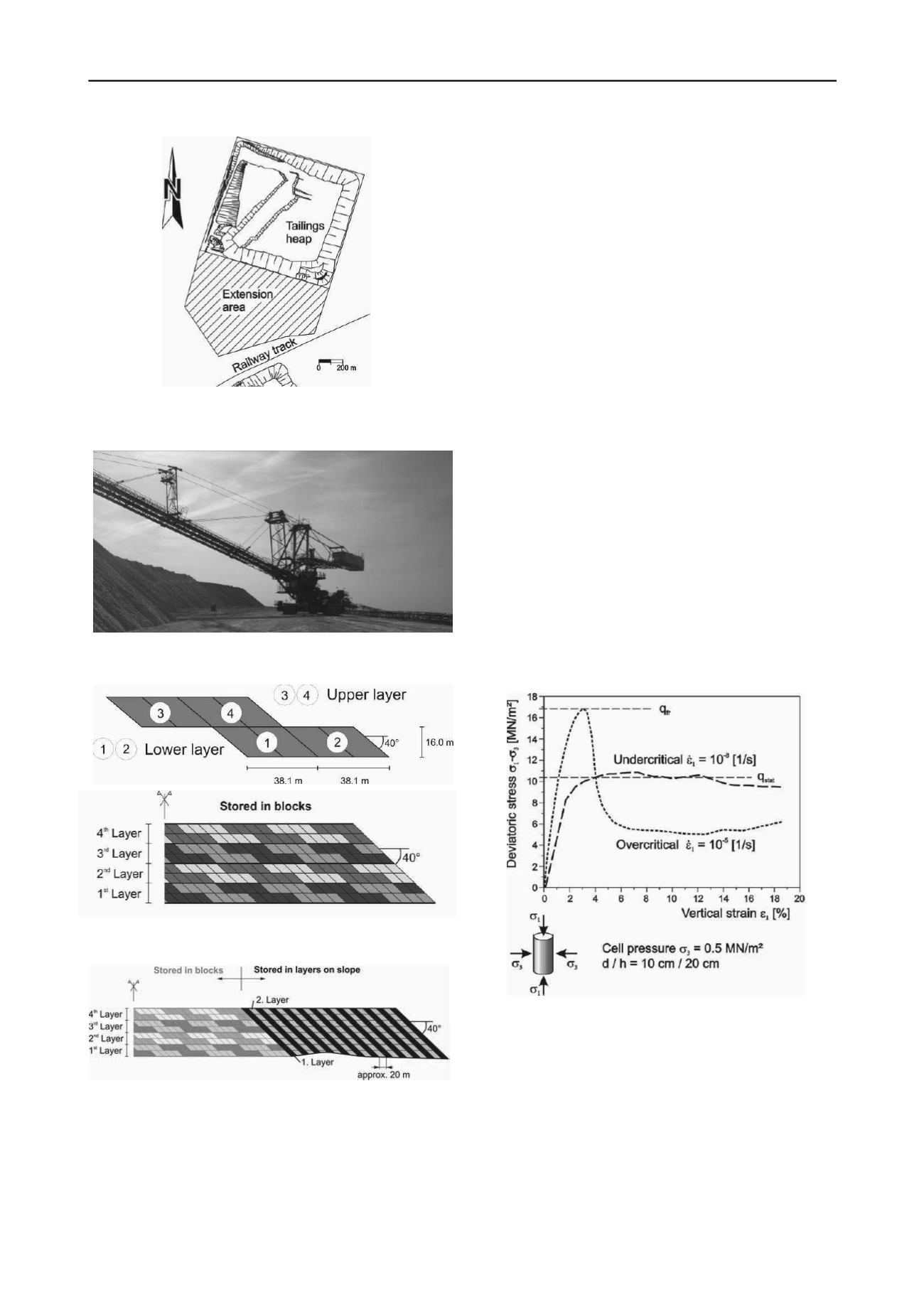

Figure 2. Site plan of the project.

Figure 3. Spreader on a heap.

Figure 4. Schematic procedure of the block storing method.

Figure 5. Schematic storing with layers on the slope.

The project area is situated in a glacial plain with a rather flat

ground surface. The soil is horizontally stratified. At the surface

a 5 m to 10 m thick layer of sand and marl glacial deposits was

investigated. Below the sand and marl deposits a 50 m thick

layer of quaternary sand with loose density was found, followed

by a 130 m to 150 m thick layer of Rupel Clay and dense sand

with varying layers of silt. At a depth of approximately 200 m

below the surface the new red sandstone begins. The

groundwater level is about 5 m below the surface.

3 MATERIAL BEHAVIOUR OF GRANULAR ROCK

SALT

The material behaviour of granular rock salt is characterized by

a distinctive time and stress dependence. Initially fresh granular

rock salt has a non-cohesive texture. After a short period the

loose, granular rock salt converts into a cohesive texture with a

high strength (Ankes 1972). The salt material attains a shear

strength with a friction angle of φ’ = 50° and a cohesion of c’ =

850

kN/m²,

as

well

as

a

stiffness

of

E

s

= 2,500 MN/m². The material behaviour of the granular rock

salt is strongly dependent to the deformation rate. High,

overcritical deformation rates lead to high strength and stiffness

of the rock salt and to brittle fracture. Small, undercritical

deformation rates lead to minor strength and stiffness and to a

plastic creep without fracture.

Directly after storing the granular stockpiled material has a

density of ρ = 1.4 to 1.5 t/m³. Due to the atmosphere, chemical

processes and the pressure because of the increasing covering

the granular stockpiled material in the core of the heap

transforms nearly into solid body.

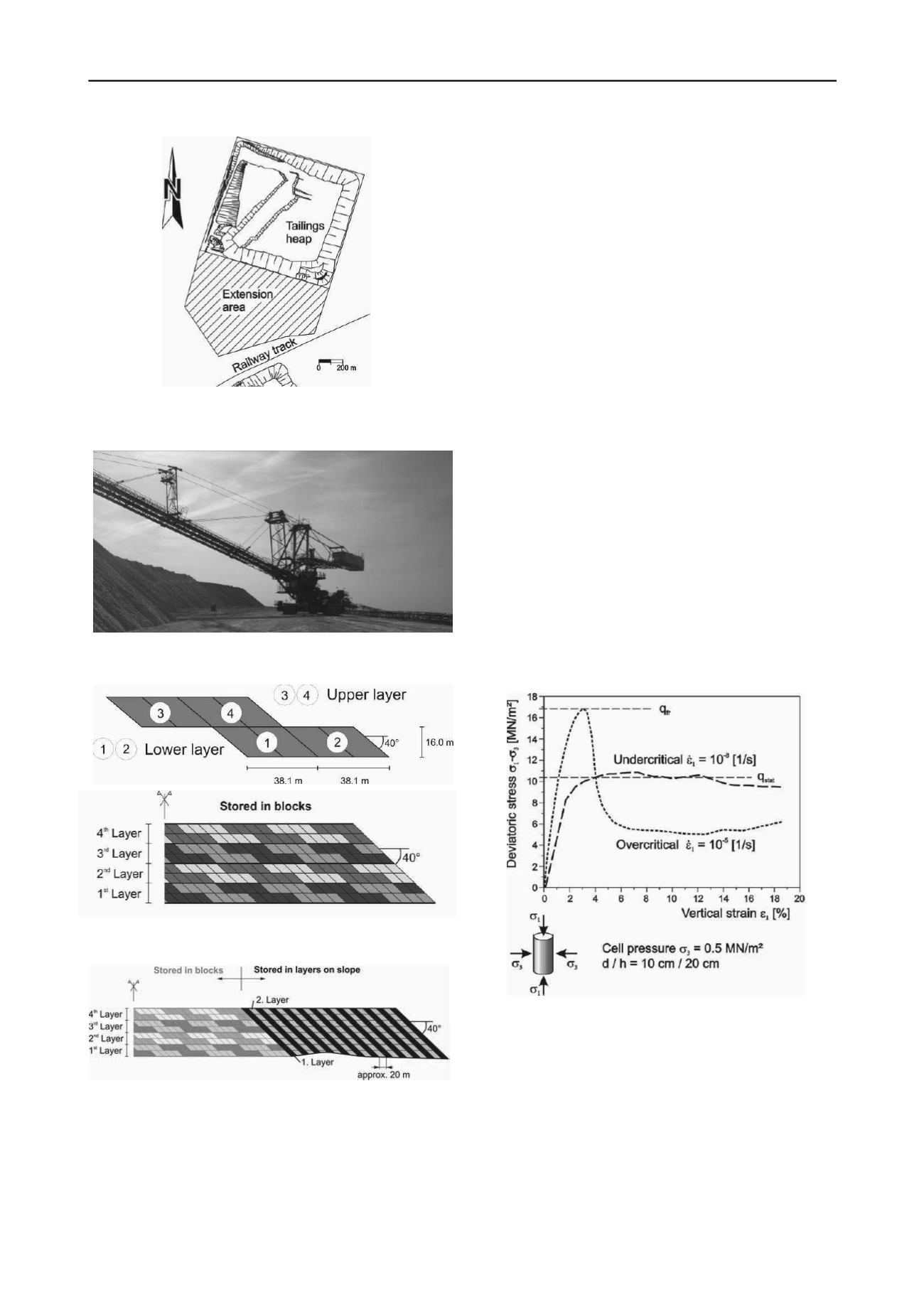

Under constant deviatoric stress the stockpiled material presents

a constant creep behaviour despite a huge strength. The material

behaviour of stockpiled material is strongly dependent on the

state of stress and of the deformation rate. Figure 6 shows the

results of two strain controlled triaxial tests on specimen of

stockpiled material, obtained from core drillings from the top of

a heap. For both tests a cell pressure of σ

3

= 0.5 MN/m² was

specified.

Both

deformation

rates

vary

by

the

factor 1,000.

Figure 6. Typical results of strain controlled triaxial tests on stockpiled

material samples.

The sample with the higher, overcritical deformation rate of

dε/dt = 10

-5

1/s presents the usual material behaviour on high

deformation rates. After the peak stress q

fr

follows a deep drop

of the deviatoric stress (brittle fracture). The sample with the

lower (undercritical) deformation rate of dε/dt = 10

-8

1/s does

not collapse. The sample creeps under a constant deviatoric

stress q

stat

.

On the left in Figure 7 is shown the specimen after the test with

undercritical deformation rate. On the right is shown the

specimen after the test with overcritical deformation rate.