2032

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(two strands each) of 2.2 m bond length were not installed into a

borehole as independent elements but were placed into the joint

corrugated PE duct (type

RCP/D-Z

with strand free lengths of

28 m, 30.4 m and 32.8 m),

•

anchors with variable stiffness of bond length

after the

patent of Škrabl, 2004, with the tendon combined of three

anchor units (2 strands each), with strand free lengths of 28.0 m,

30.4 m and 32.8 m, and with strand bond lengths of 7.0 m, 4.6

m and 2.2 m (type

RCP/D-I

).

3 IN-SITU TESTING

The test field has been located at the level of the middle berm of

a larger retaining wall, where load-bearing stratum consists of

marl and silty marls with thin lenses of siltstone and sandstone.

A total of 18 anchors were installed: three reference RCP/D

anchors and five anchors of each alternative type (RCP/D-K,

RCP/D-Z and RCP/D-I). Boreholes, deflected 15° downwards,

were drilled with a chisel (

∅

140 mm) using air-flushing for the

removal of drill spoil. The ratio of 6-strand anchor steel cross-

sectional area to cross-sectional area of the borehole equaled

5.5% of the theoretical cross-sectional area of the borehole. The

appearance of moist in the ground was repeatedly detected in

the region of the anchor bond lengths. Cement grout with w/c

ratio of 0.42 was used for grouting within the PE encapsulation

as well as for the collar of the borehole with an average grout

consumption of about 17 dm

3

/m

1

.

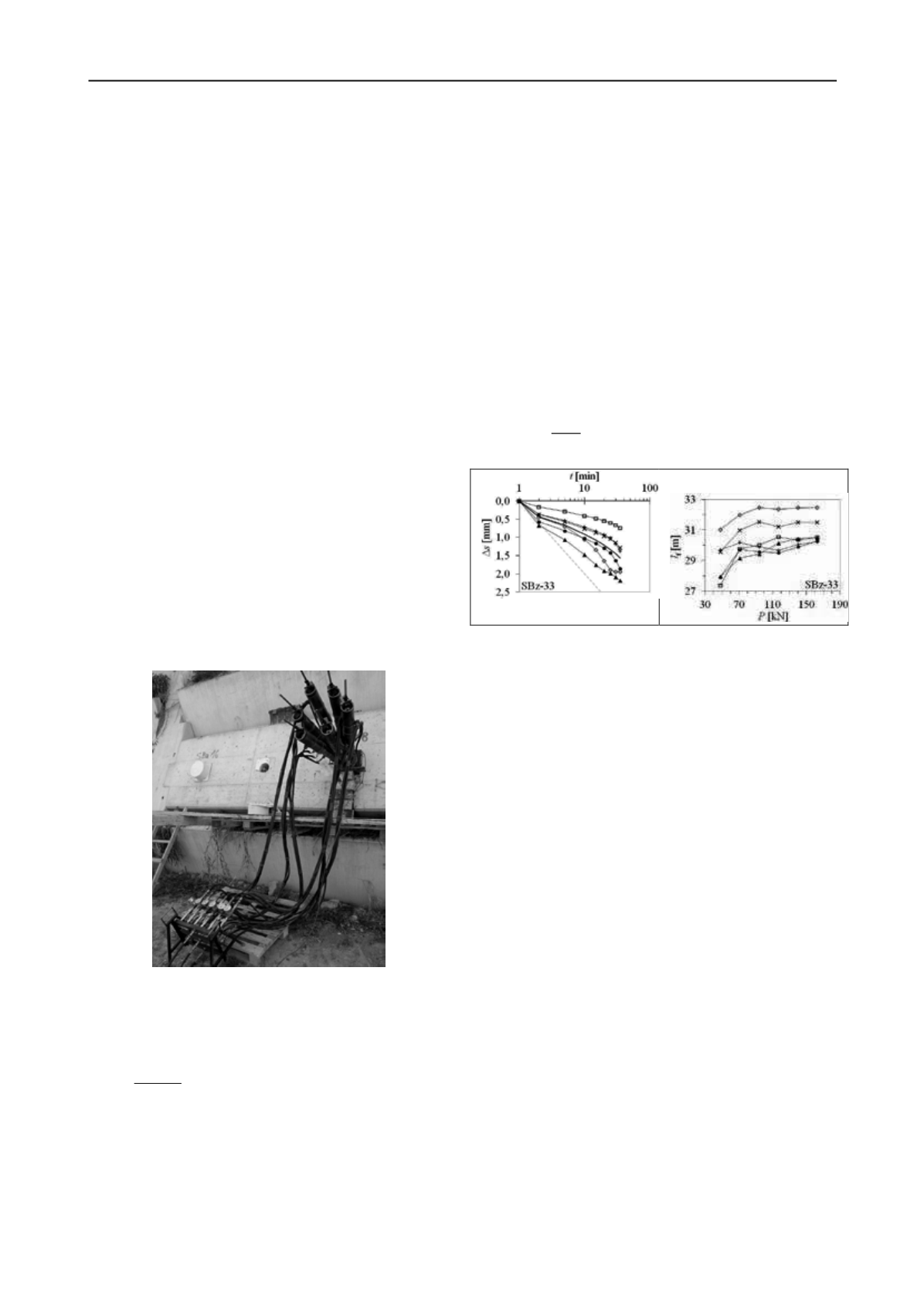

At in-situ testing individual strands were tensioned with

monostrand jacks, connected to a joint hydraulically

synchronized system (Fig. 2)

.

An electrical load cell was used

for the precise adjustment of stressing forces. Extensions and

creep behavior of strands were measured with digital

displacement transducers, attached on the monostrand jacks.

Figure 2. Test setup for simultaneous stressing of all strands of

prestressed ground anchors using monostrand jacks.

As a measure for the assessment of load-bearing

characteristics of anchor bond lengths creep displacement rate

k

was used (Ostermayer, 1975):

=

2

1

⁄

(1)

where

s

1

and

s

2

are head displacements at times

t

1

and

t

2

,

respectively. For the failure of anchor bond length the critical

creep displacement rate

k

crit

= 2 mm was used.

All reference anchors and one anchor of each alternative

type were tested up to the maximum test load

P

pv

= 1254 kN (80

% steel tensile strength

R

m

) or until failure of anchor bond

length was reached (

investigation test

- IT). Other alternative

anchors were tested using the same procedure, except that the

test was stopped at the first sign of anchor bond length failure,

i.e. as soon as

k

crit

appeared (

comprehensive suitability test -

CST). All test field anchors were tested according to the loading

procedure and methodology for IT as described in Swiss

standard SIA 267/1, which is very similar to test Method 1 of

standard EN 1537: each anchor was loaded in eight incremental

cycles from a datum load

P

a

= 150 kN (10 %

R

m

) to the

maximum test load

P

pv

. The increments of strand extensions

were measured at the end of specified time intervals, which

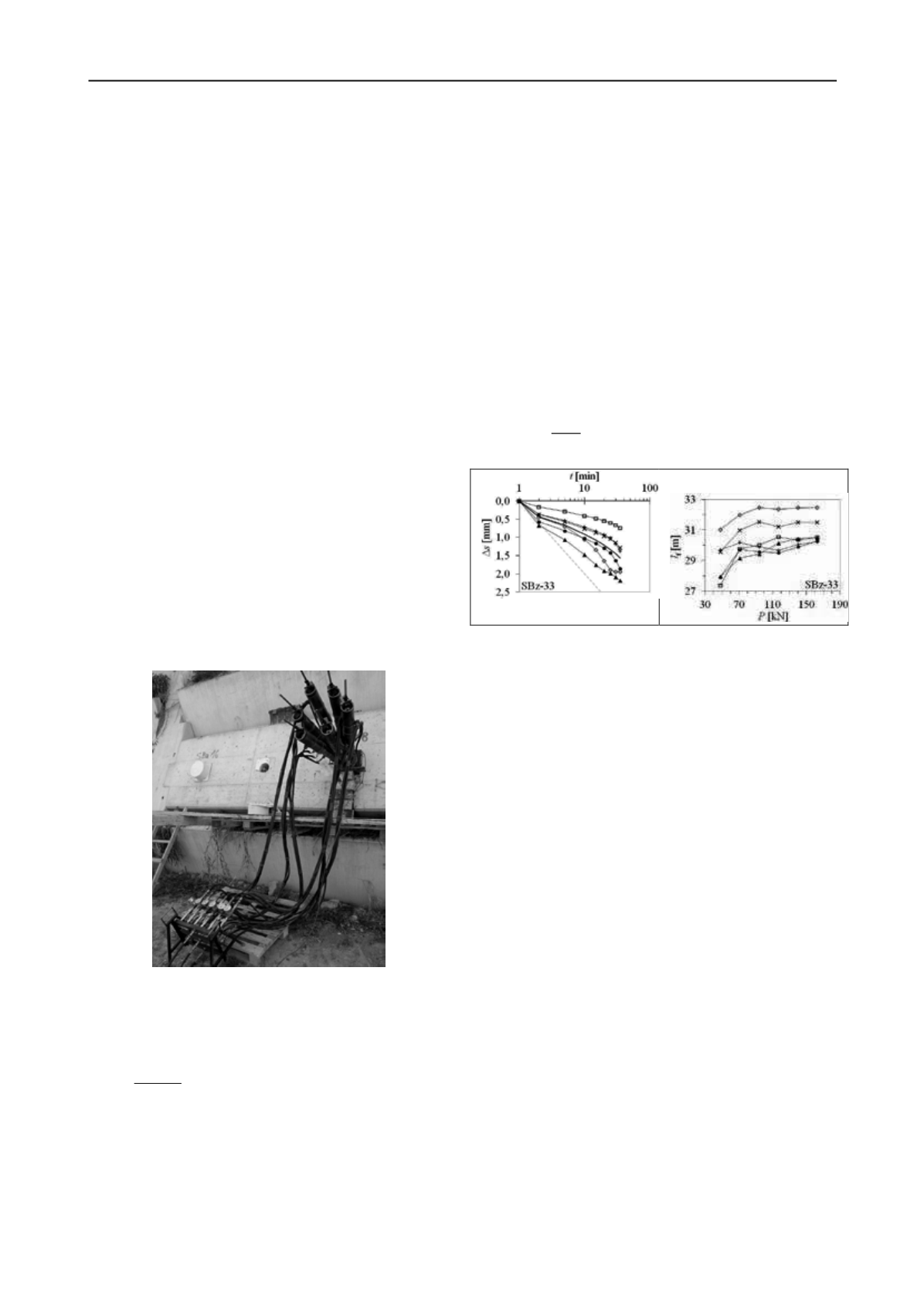

were used for the evaluation of

k

values. Individual strand

extensions as well as average extensions for all strands of the

RCP/D-I anchor SBZ-33 at load level

P

6

= 978 kN of CST are

presented on the left diagram of Fig. 3. The right diagram shows

the development of apparent free lengths

l

f

of individual strands

during the same CST, which is based on the measured elastic

displacement

∆

s

el

at load decreasing from current level

P

i

to the

initial level

P

a

, knowing the characteristics of the tendon (cross-

section area

A

p

and modulus of elasticity

E

p

):

f

=

∆

el

a

p

p

(2)

Figure 3. Measured increments of displacements of the anchor SBz-33

(type RCP/D-I) at load level

P

6

of CST (left), apparent free lengths of

individual strands

l

f

during CST (right).

The behaviour characteristics of anchor bond length could be

recognized only on the basis of strand extensions, measured on

displacement transducers, fixed on the monostrand jacks. The

problem is that due to the limited amount of data and the

inability of physical insight into the bond lengths deep in the

load bearing stratum, we cannot always directly link measured

extensions with creep displacement rate

k

of the bond length

(i.e. it is not necessary that each measured strand extension

actually originates from the bond length deterioration).

Therefore, in the analysis of the in-situ test results it is

recommendable to compare the

k

values of individual strand

with the

k

values of other individual strands of the same tendon,

with

k

values of anchor units (average of two strands, only at

types RCP/D-Z and RCP/D-I), with the average

k

values of all

strands, as well as with the permanent displacements

∆

s

bl

and

apparent free lengths

l

f

, obtained after each loading stage. In

order to prevent sudden failures of bond lengths at CST, an

appropriate software tool was prepared to enable simultaneous

recording and evaluation of the most important behaviour

parameters of an anchor during in-situ test.

4 ANALYSIS OF RESULTS OF THE IN-SITU TESTING

There are several possible failure mechanisms at the anchor

bond length, which occur at the IT of prestressed ground anchor

with a comprehensive corrosion protection: inside or outside the

PE corrugated duct, under some circumstances it may also come

to the rupture of PE duct. The types and incidences of individual

mechanisms depend on the design of bond length and packing

connections at the transition between strand free and bond

lengths, possible surface contamination of the bare strand bond

length, the design, dimensions and distribution of the constituent

components of anchors, local conditions in the ground,

configuration of strands in the bond length, drilling and flushing

techniques as well as specifics of grouting. According to the