2000

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(

S

u

) was 13

kPa

as measured by lab shear vane method along

the tank depth.

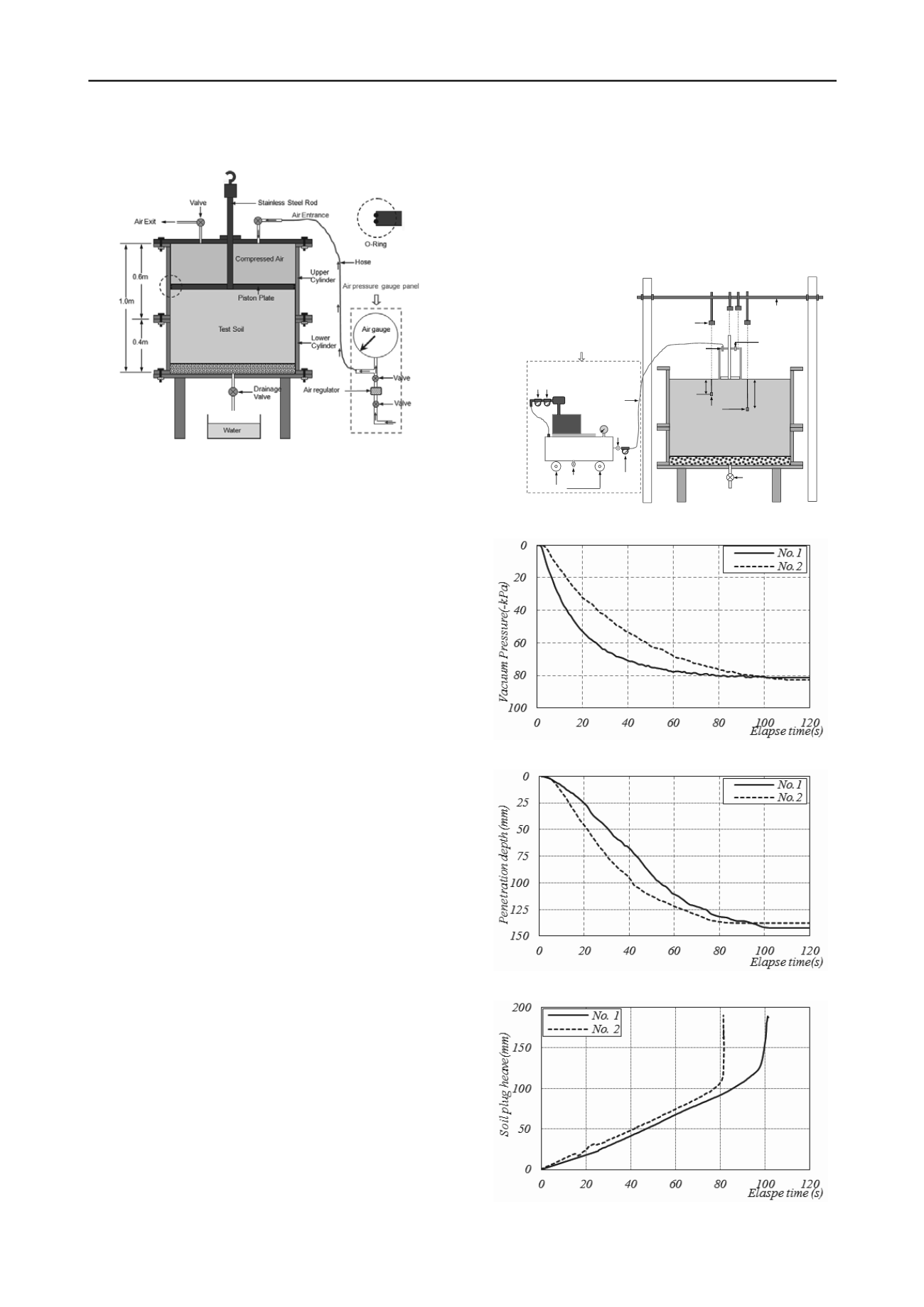

Figure 1 Consolidation procedure of kaolin

2.2 Caisson Installation

The caisson was made by an inner steel skirt and covered by a

layer of concrete with its total height of 400

mm

, diameter of

205

mm

and wall thickness of 22.5

mm.

The Caisson was

assembled with a designed piston which made it possible to

monitor the process of soil plug during installation tests. The

piston consisted of a ‘Teflon’ plate and a steel rod. The plate

was 25 mm thick and 150 mm in diameter with steel rod

mounted in the middle. A crew with a height of 20 mm was

used to strengthen the connection of the rod and the plate. Thus

the clear internal skirt length of the caisson reduced from

400

mm

to 335 mm. The total weight of caisson and piston was

27.2

kg

.

The vacuum loading system was composed by a vacuum

pump (EVISA E25), a vacuum gauge, two bowl vacuum filters,

a vacuum tank, and a hose, as illustrate in Figure 2. Note that

during suction installation tests, one more absolute pressure

transducer was mounted in the caisson cavity to test the vacuum

pressure.

The miniature pore water pressure transducers (PPTs) were

used in this model test to measure the pore water pressure

changes. Such a miniature size was necessary to minimize the

influence of the measuring device to the overall soil behavior

during model test. Before a model test, all PPTs were calibrated

by using water pressure generated in a triaxial cell. The

preinstalled positions of the PPTs on the top cap are shown in

Figure 2.

The displacement of the piston in the consolidation tank or

that of the suction caisson during the model test was measured

by laser sensor (KEYENCE IL series) which had an effective

measurement range from 20

cm

to 1.0

m

. The displacement of

piston rod in caisson was also measure by another laser sensor

by mounting an aluminum plate on to the rod. The third laser

sensor was mounted on the frame to measure the displacement

of suction caisson. Two other laser sensors were used to

measure the soil movement on caisson sides as shown in Figure

2. This contact-free displacement measuring method offered

both reliability and convenience.

2.3 Model Test Results

The model test results of caisson penetrated into the soil bed

assisted by vacuum pressure was discussed in this section. Since

the self-weight was not able to provide enough penetration force

for caisson insertion, the caisson was manually penetrated into

soil in a short distance to ensure that the applied suction would

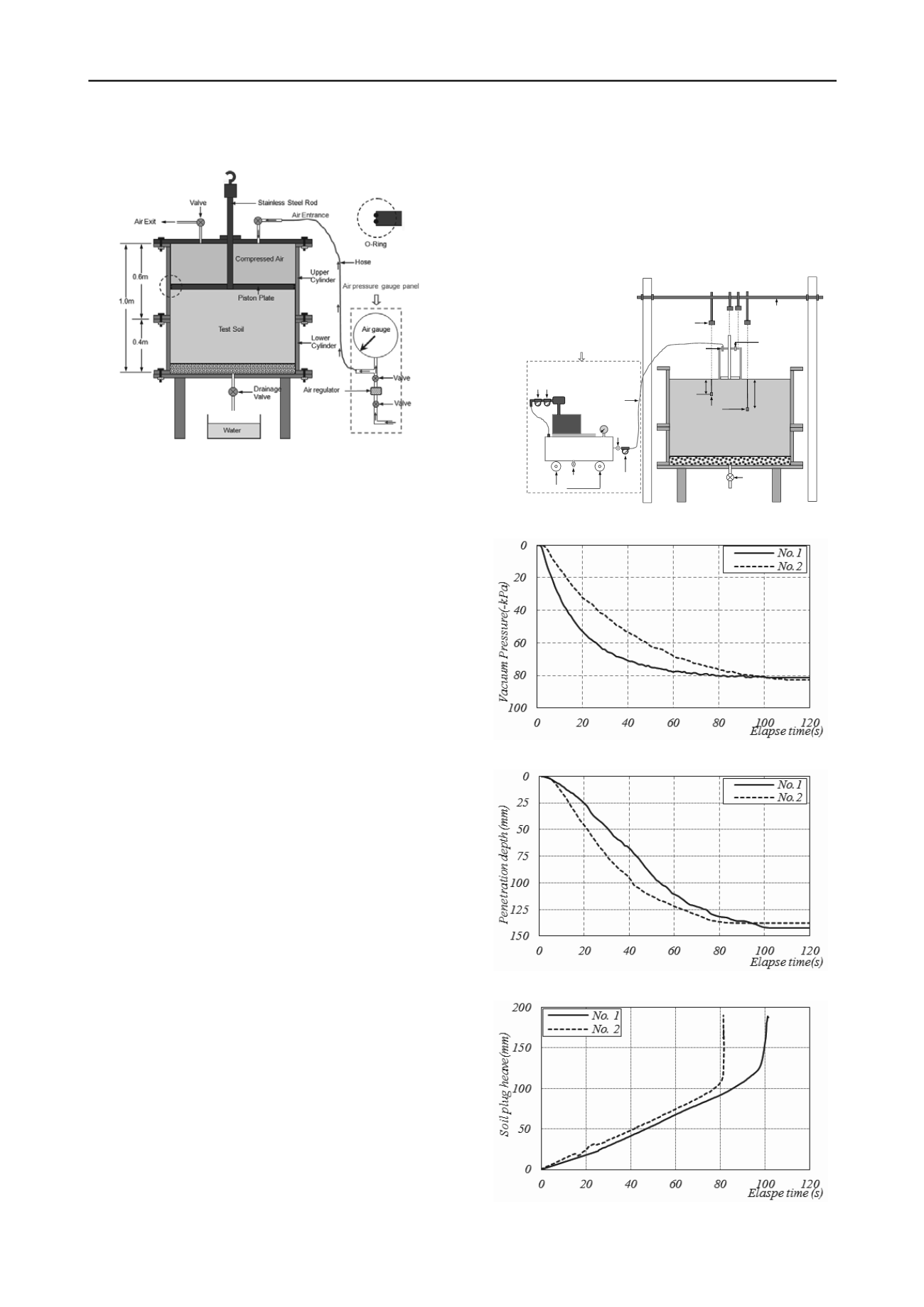

not leakage. The applied vacuum pressures in Model Test

No. 1

and

No. 2

during the suction installation are shown in Figure 3.

It can be seen that the vacuum pressure increased very slowly

till to the largest magnitude of -80

kPa

. The displacements of the

caisson and soil plug are shown in Figure 4 and Figure 5,

respectively. It can be seen that the soil plug was moving

upward throughout the installation procedure. At the beginning,

the soil plugs increased nearly linearly with the time. A the time

of 81

s

for test

No. 1

and 96

s

for test

No. 2

, there was a sudden

jump in the displacement. This happened because the soil plug

was broken suddenly. During this period, the caisson had no

penetration.

PPTs

Laser sensor

8cm

20cm

Soil surface

Test Soil

Drainage Valve

Hose

Absolute pressure

Transducer

Air vent

Vacuum gauge

Vacuum

Pump

Bowl filter

Vacuum tank

Bowl filter

Wheel

Drainplug

Frame for laser sensors

Vacuum loading system

Air valve

Figure 2 Installation of suction caisson

Figure 3 Vacuum pressure vs. time curve

Figure 4 Penetration depth vs. time curve

Figure 5 Penetration depth vs. soil plug heave curve