1998

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

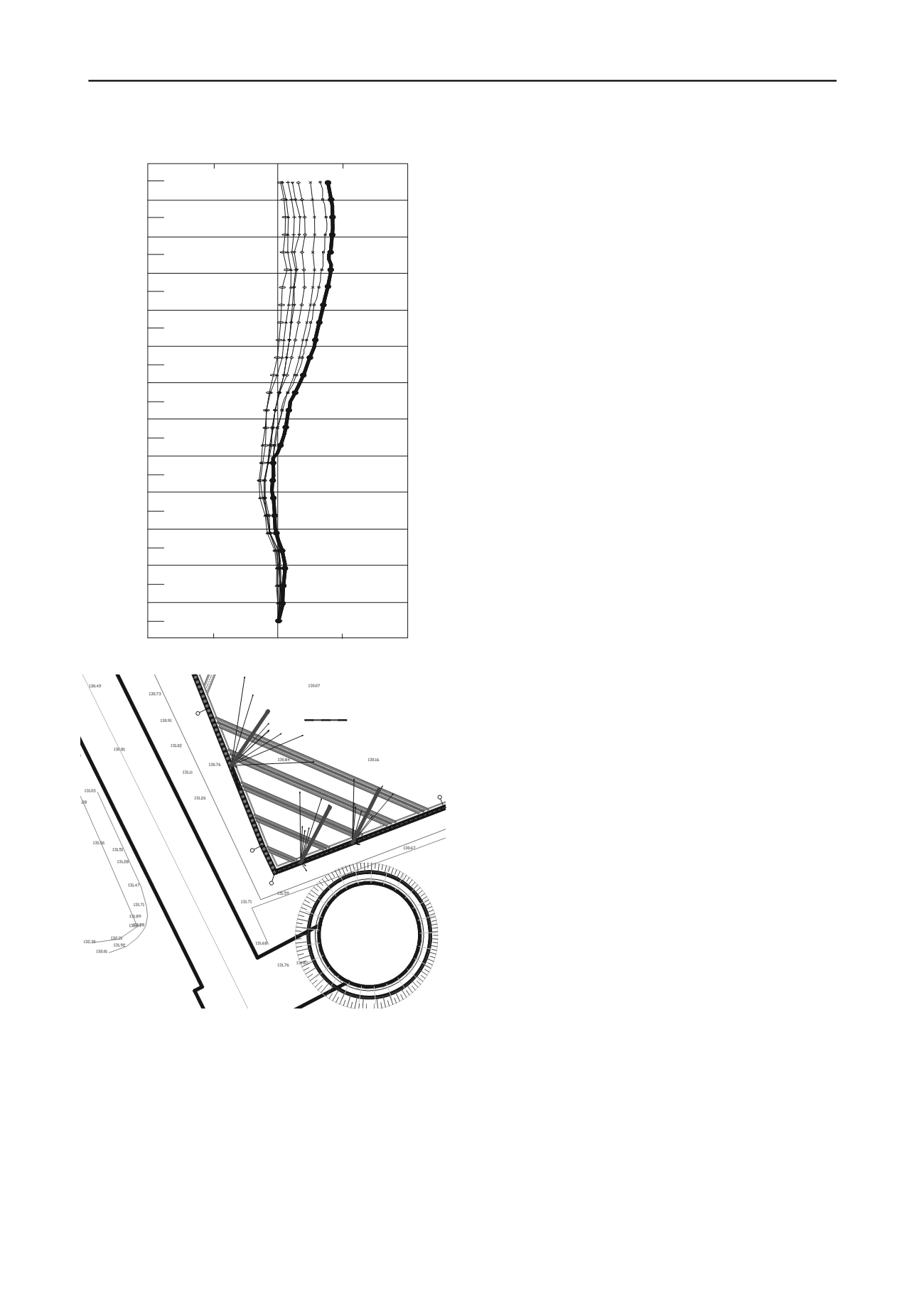

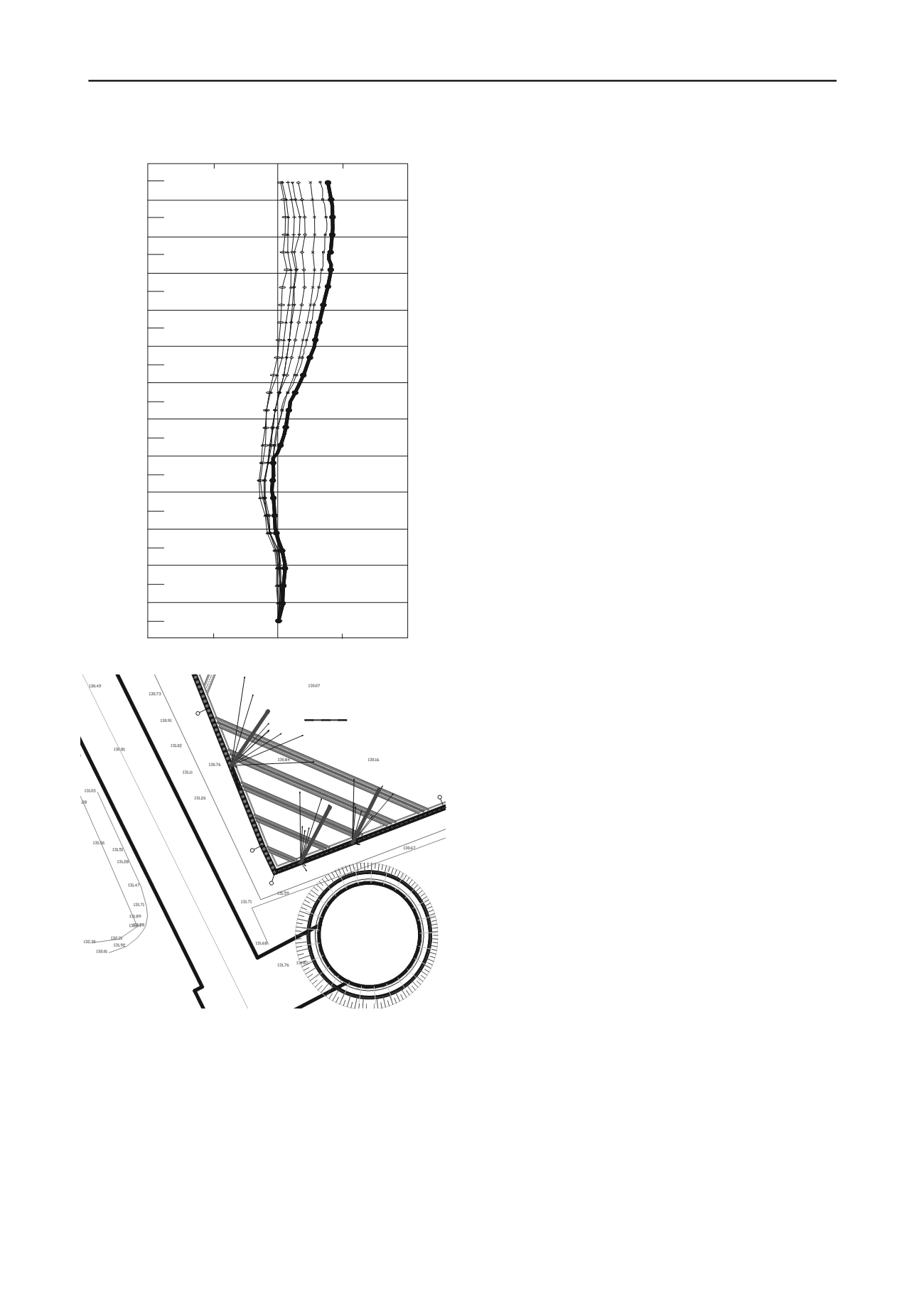

Figure 8. (a) Inclinometer (b) optic survey results

In addition to deformation monitoring, the axial forces (and

dependently stresses) on the steel struts were monitored by

means of strain-gauges. As expressed in Table 4, the maximum

axial force on the steel struts were found as 263 kN/m

(normalized axial force ~1500 kN). This value corresponds to a

stress value of ~125 MPa. The maximum axial force from the

strain-gauge readings is calculated as ~1620 kN corresponding

stress is calculated as 130 MPa. The mean axial deformation

horing wall was calculated as ~6.2 mm,

can be concluded Finite Element Analyses (preferably including

ically complex problems) are useful tools

Und

Geological

Characteristics of Istanbul Greywackes”, 10

th

IAEG2006, Paper

395, Nothingam, UK.

Undul O. and Tugrul A, 2006. “The Engineering Geology of Istanbul,

Turkey”, 10

th

IAEG2006, Paper 392, Nothingam, UK.

perpendicular to the s

which was derived from the results of axial compression values

(

L

17.5 mm) from the strain-gauges.

5 CONCLUSIONS

In the deep excavation project in Istanbul, geotechnical

dimensioning of the shoring system was defined by means of

Limit Equilibrium and Finite Element method of analyses. Both

2D and 3D FE analyses were adopted for evaluation of the

interaction between the adjacent tunnel & shaft (which were

still under construction and standing with their temporary

supports) with the deep excavation. The shaft and the tunnel

design had not foreseen the deep excavation at their close

vicinity, so the responsibility of ensuring the stability of the

excavation itself and of the tunnel and shaft was the sole

responsibility of the deep excavation support system designer.

Based on the results gathered from this project, it can be

concluded that the 2D FEA leads to safer results (slightly higher

deformation values and section forces) compared to 3D FEA.

This conclusion is also in accordance with our own expertise in

deep excavation design works with similar circumstances.

Moreover, the data gathered from the geotechnical

monitoring program revealed compatible in-situ performance

with the analyses results (both on deformations and stresses). It

3D FEA in geometr

under expertise whereby supported with in-situ monitoring.

6 REFERENCES

Güler F.E. and Bakilar G.S., 2008. “Related Geotechnical-Geological

Investigation Report”, Istanbul

“Periodic Geotechnical Instrumentation Reports of the site”, ELC

Group Inc., Istanbul

“Engineering Design Report of Pedestrian Tunnels and Shaft”, Yuksel

Proje International Inc., 2010, Ankara

O DIANA BV. V.9.4.3 “

TN

Users Manual Analysis Procedures”, Delft

PLAXIS BV. V.2D.2011 “Reference Manual”, Delft

ul O. and Tugrul A, 2006. “The Engineering

-15.0

0.0

15.0

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

22.0

24.0

26.0

(a)

A

B

N

M

B'

Tip-AStrut

Tip-BStrut

Tip-CStrut

Tip-DStrut

Tip-EStrut

B5

B3

B2

2

1

2

1

2

1

0 mm

1 mm

2 mm

3 mm

5 mm

4 mm

3

3

5

7

7

8

8

8

9

9

9

10

10

10

11

11

12

12

12

13

13

13

Latest

Latest

Latest

6

Maximumdfr. at shaft location : ~7mm

Maximumdfr. at tunnel location : ~8mm

(b)