1990

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

\

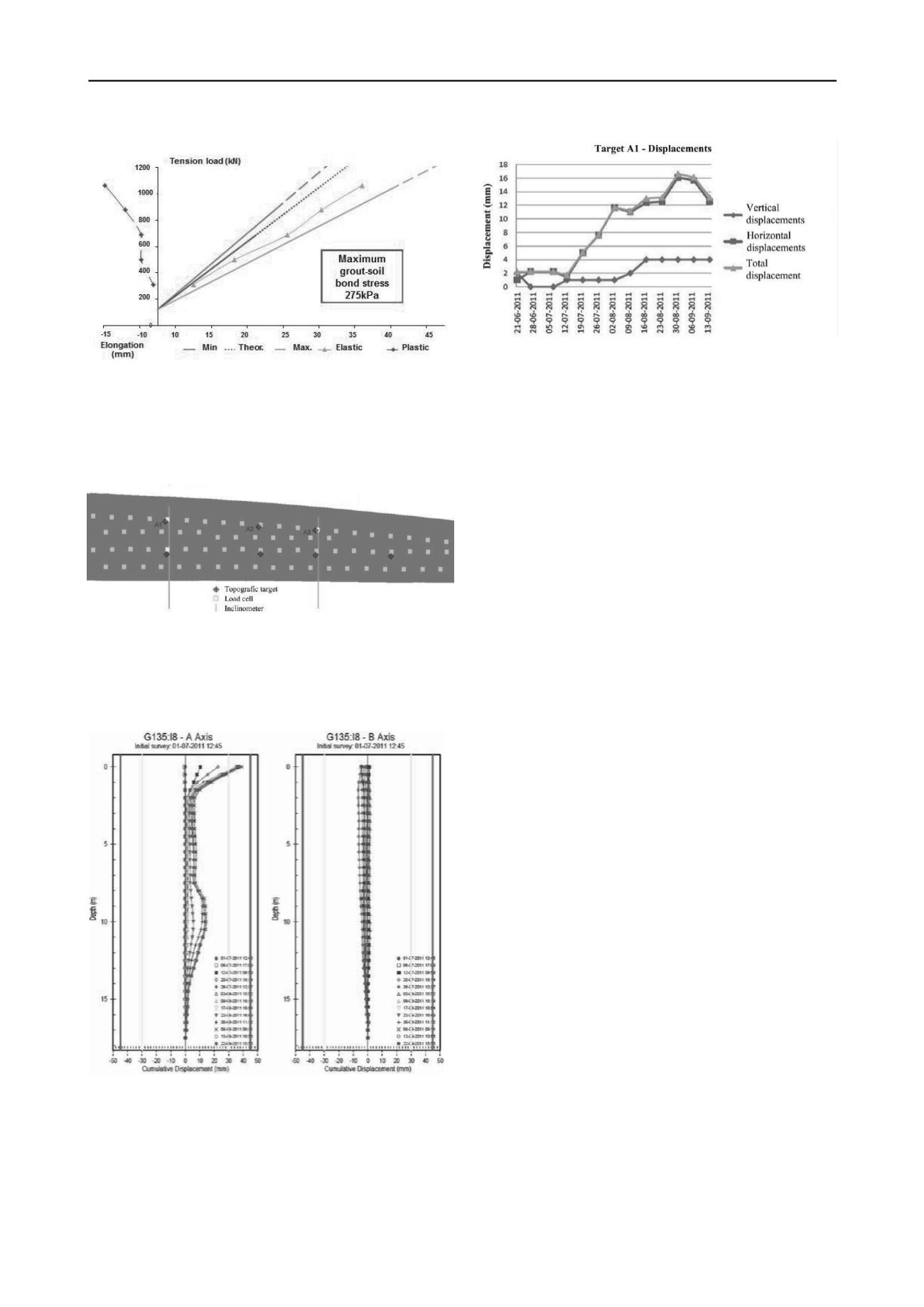

Figure 12. Displacement recorded at the topographic target A1.

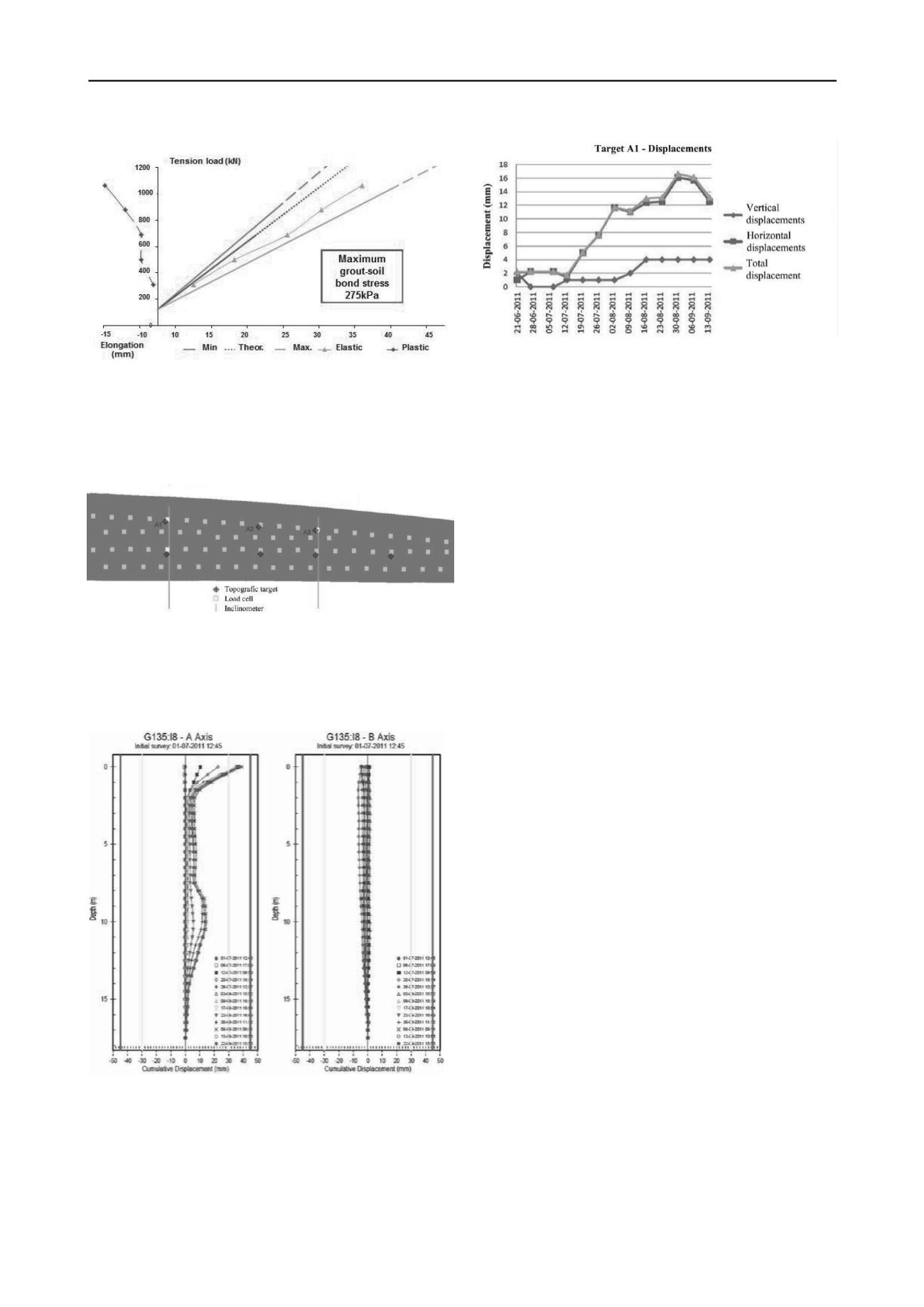

Figure 9. Main results of the ground anchor suitability test

.

6 MAIN CONCLUSIONS

5 CSM WALL PERFORMANCE

The implemented monitoring and observation plan, is shown on

Figure 10, including 2 inclinometers and 7 topographic targets.

The case study presented in this paper shows the good

performance, mainly low deformations, of an anchored

retaining structure, combining CSM panels with a reinforced

concrete lining wall, leading to the optimization of both the

construction overall schedule and budget in a complex

geotechnical and site conditions. It was also shown that the use

of commercial FEM software with appropriated input data gives

a reasonable prediction of the main displacements, which are

critical for the verification of both the ultimate and

serviceability limit states, for all the excavation phases.

Figure 10. Monitoring and observation plan.

7 ACKNOWLEDGEMENTS

Figure 11 shows that the maximum displacement was

observed at 10 m depth, corresponding to 15 mm (inclinometer

I8).

The authors wish to thank to “Fundação para a Ciência e a

Tecnologia” (FCT) for the financial support under the strategic

project PEst-OE/ ECI/UI4047/2011. In addition, the authors

would like to thank the contribution of Ângelo Pereira.

8 REFERENCES

Ameratunga J.; Brown D.; Ramachadran R.; Denny R. (2009). “Ground

improvement for a large above ground storage tank using cutter soil

mixing columns.”

Proc. 17th International Conference on Soil

Mechanics and Geotechnical Engineering

, Alexandria, Egypt, pp.

2280-2283.

Bruce D.A. 2000. An introduction to the deep soil mixing methods as

used in geotechnical applications.

Federal Highway Administration

,

Georgetown.

Capelo A., Gomes Correia A., Ramos L.R., Pinto A. And Tomásio R.

2012. Modeling and monitoring of an excavation support using

CSM.

4th International Conference on Grouting and Deep Mixing

,

New Orleans, Louisiana, USA, ASCE, GSP (in printing).

Larsson S. 2003. Mixing processes for ground improvement by deep

mixing.

Department of Civil and Environmental Engineering,

Royal Institute of Technology in Stockholm

.

Marzano I.P., Osman A.A-M., Grisolia M., Al-Tabbaa A. 2009.

Mechanical performance of different stabilised soils for application

in stratified ground.

17th International Conference on Soil

Mechanics and Geotechnical Engineering

, Alexandria, Egypt, pp.

2276-2279.

Pereira A. 2011.

Application of Cutter Soil Mixing Technology in

containment of a retaining wall anchored linear

. MSc dissertation,

Guimarães (in Portuguese).

Figure 11. Displacement recorded at the inclinometer I8.

In Figure 12 it is observed that the maximum vertical

displacement is 4 mm and that the maximum horizontal

displacement is 17 mm.

These results show that the FEM analysis, with the presented

input data, has given a good analytical prediction of the

observed horizontal displacement, mainly confirming the depth

where the maximum horizontal displacement occurred.

Pinto A., Tomásio R., Pita X., Pereira A. and Peixoto A. 2011. Cutter

Soil Mixing Solutions in Portugal on Hard Soils and Weak Rocks.

Proc. 15th European Conference on Soil Mechanics and

Geotechnical Engineering

, September 2011, Athens, Greece, Part 2

– 3.3 – Ground Reinforcement, pp. 1037–1042.

Pinto A., Tomásio R., Godinho P., 2013. Innovative Solution of King

Post Walls combined with CSM.

Proc. 18th European Conference

on Soil Mechanics and Geotechnical Engineering

, Paris, France.

Porbaha, A. (2000). State of the Art in Deep Mixing Technology. Part

IV: Design Considerations.

Ground Improvement

, 4(3), 111–125.