1982

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

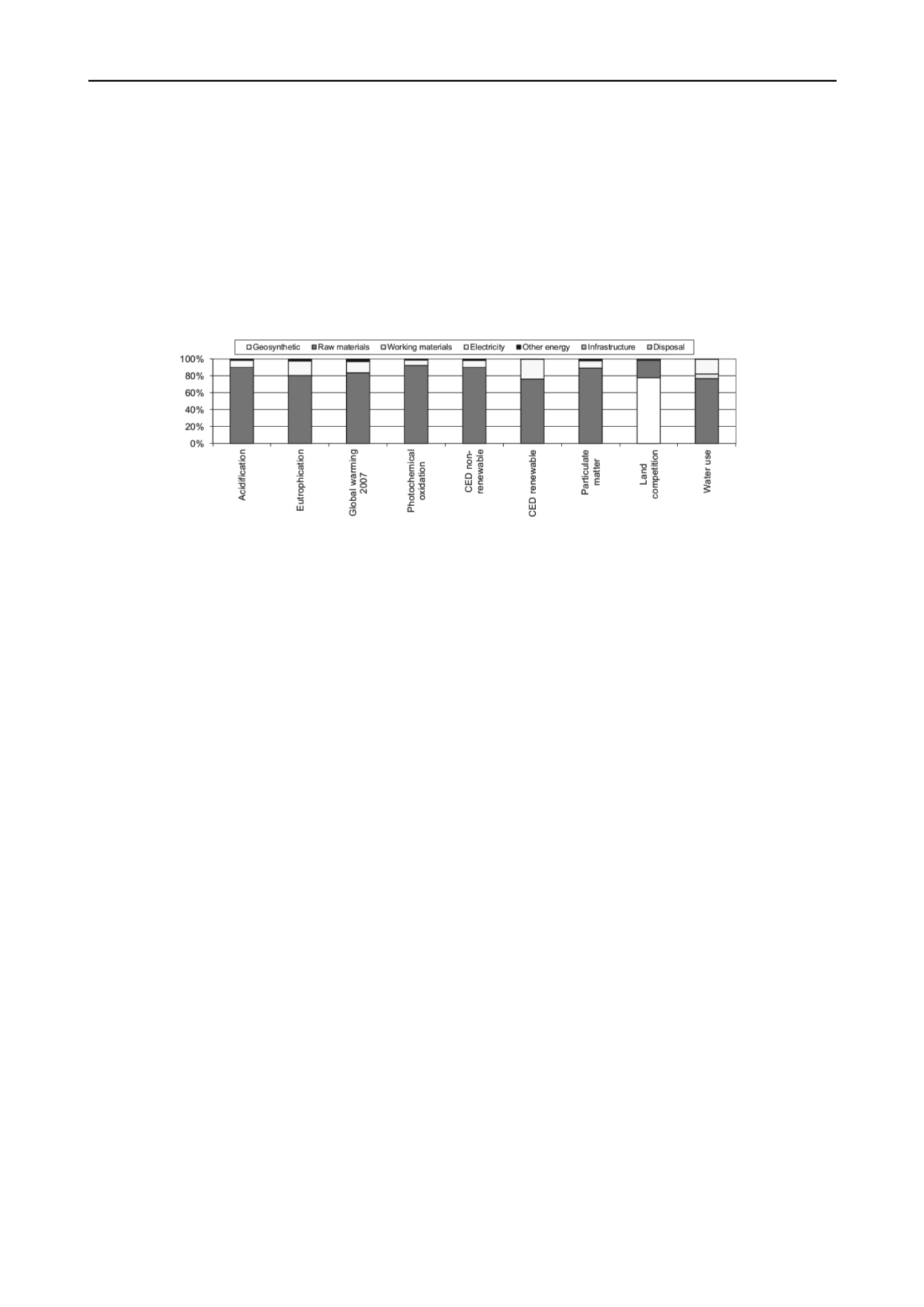

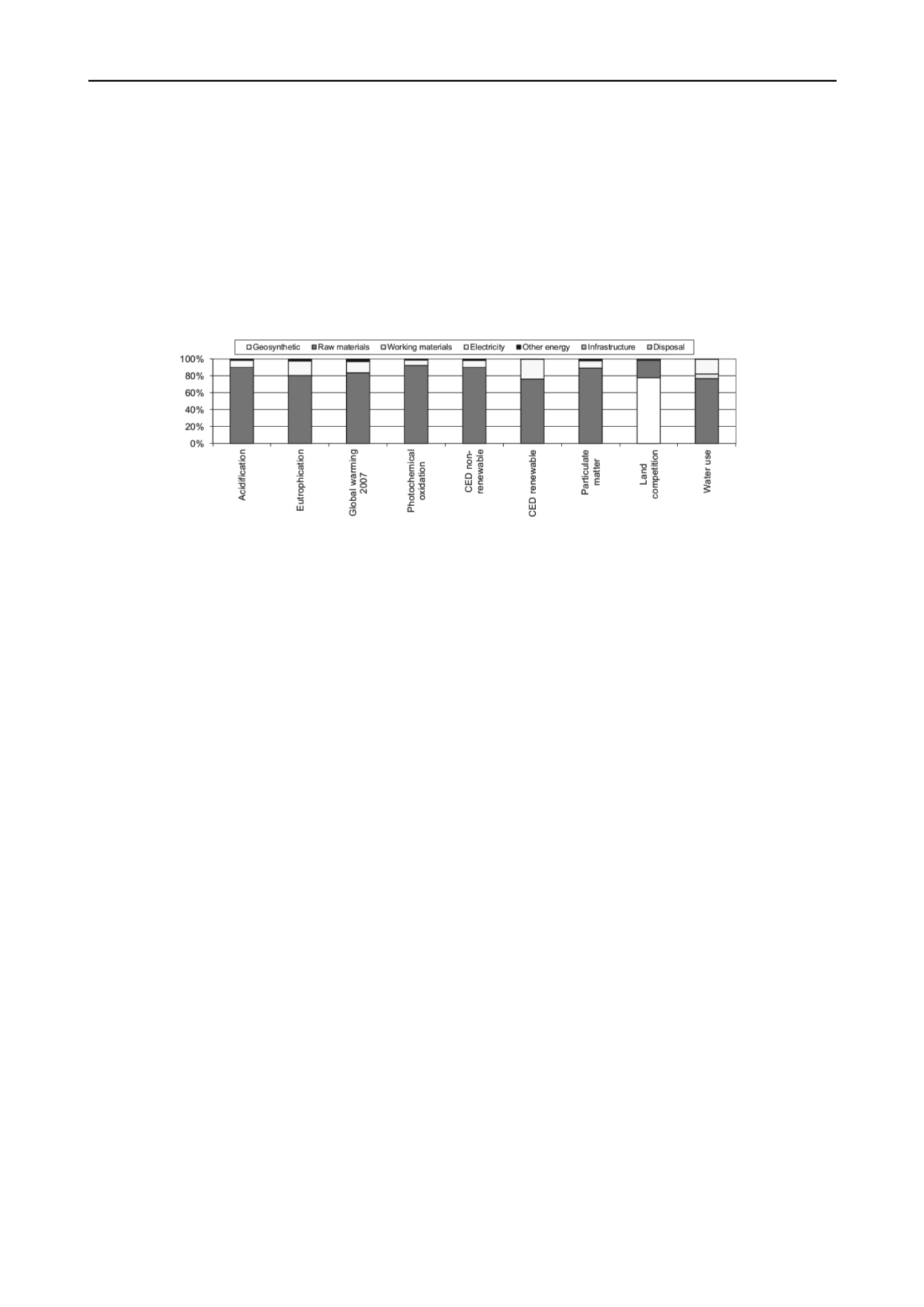

includes different types of plastics. Country-specific

electricity mixes are modelled for each company and thus

impacts of electricity consumption depend not only on the

amount of electricity needed but also on its mix. The higher

share of electricity in CED renewable can be explained by the

use of hydroelectric power plants in the electricity mixes of

several factories. And the relatively high share in

eutrophication is mainly due to electricity from lignite.

The share of heating energy and fuel consumption for

forklifts is between 0.01 % (land competition) and 2.8 %

(global warming) and is thus not considered to be of primary

importance. With regard to land competition the geosynthetic

production plays an important role. The impacts are

dominated by the direct land use, i.e. land which is occupied

by the manufacturer plant in which the geosynthetic is

produced. Indirect land uses, i.e. land occupation stemming

from upstream processes, are significantly lower because no

land occupation is reported in the inventories of plastic

feedstock and no land intensive products such as wood are

used in considerable amounts. Water consumption is included

in the working materials. As a consequence, this category

bears about 5 % of the total amount of water used.

Figure 3. Environmental impacts of the life cycle of 1 kg geogrid. Geosynthetic includes direct burdens of the geosynthetic production. Raw materials

include plastic, extrusion if necessary and additives, working materials include water (tap and deionised) and lubricating oil, other energy includes

thermal energy and fuels, infrastructure covers the production plant and disposal comprises wastewater treatment and disposal of different types of

waste.

5 DISCUSSION AND CONCLUSION

The use of geosynthetics leads to lower environmental impacts

of slope retention in all indicators investigated. The specific

climate change impact of the construction of the slope retention

(1 m slope retention with a 3 meters high wall) using

geosynthetics is about 1 ton CO

2

-eq per meter lower compared

to a conventional alternative. This difference is equal to about

84 % of the overall climate change impact of the construction

and disposal efforts of an entire conventional slope retention

system during its 100 years lifetime.

If a Euro5 lorry with lower exhaust emissions than an average

fleet lorry is used for the transportation of materials, the

environmental impacts of both cases are somewhat reduced

regarding some indicators. However, this does not affect the

overall conclusions of the comparison.

Slope retentions are individual solutions in a particular

situation. The height of slope retention walls and the horizontal

loads on it may differ, which may lead to differences in

thickness and reinforcement. Thus, generalising assumptions

were necessary to model a typical slope retention. Data about

on-site material used, gravel extraction, concrete and the use of

building machines are based on generic data and knowledge of

individual civil engineering experts.

Based on the uncertainty assessment it can be safely stated that

the geosynthetics reinforced slope retention shows lower

environmental impacts than the concrete wall. Despite the

necessary simplifications and assumptions, the results of the

comparison are considered to be significant and reliable.

A geosynthetic reinforced wall used for slope retention

constitutes a different system compared to a concrete reinforced

wall. Nevertheless, both systems provide the same function by

enabling the build-up of steep walls. Compared to the

conventional slope retention, the geosynthetic reinforced wall

substitutes the use of concrete and reinforcing steel, which

results between 63 % and 87 % lower environmental impacts.

6 REFERENCES

ecoinvent Centre (2010) ecoinvent data v2.2, ecoinvent reports No. 1-

25. Swiss Centre for Life Cycle Inventories, Duebendorf,

Switzerland, retrieved from:

.

Frischknecht R., Jungbluth N., Althaus H.-J., Bauer C., Doka G., Dones

R., Hellweg S., Hischier R., Humbert S., Margni M. and Nemecek

T. (2007) Implementation of Life Cycle Impact Assessment

Methods. ecoinvent report No. 3, v2.0. Swiss Centre for Life Cycle

Inventories, Dübendorf, CH, retrieved from:

.

Goedkoop M., Heijungs R., Huijbregts M. A. J., De Schryver A., Struijs

J. and van Zelm R. (2009) ReCiPe 2008 - A life cycle impact

assessment method which comprises harmonised category

indicators at the midpoin and the endpoint level. First edition.

Report I: Characterisation, NL, retrieved from: lcia-recipe.net/.

Guinée J. B., (final editor), Gorrée M., Heijungs R., Huppes G., Kleijn

R., de Koning A., van Oers L., Wegener Sleeswijk A., Suh S., Udo

de Haes H. A., de Bruijn H., van Duin R., Huijbregts M. A. J.,

Lindeijer E., Roorda A. A. H. and Weidema B. P. (2001a) Life

cycle assessment; An operational guide to the ISO standards; Part

3: Scientific Background. Ministry of Housing, Spatial Planning

and Environment (VROM) and Centre of Environmental Science

(CML), Den Haag and Leiden, The Netherlands, retrieved from:

.

Guinée J. B., (final editor), Gorrée M., Heijungs R., Huppes G., Kleijn

R., de Koning A., van Oers L., Wegener Sleeswijk A., Suh S., Udo

de Haes H. A., de Bruijn H., van Duin R., Huijbregts M. A. J.,

Lindeijer E., Roorda A. A. H. and Weidema B. P. (2001b) Life

cycle assessment; An operational guide to the ISO standards; Parts

1 and 2. Ministry of Housing, Spatial Planning and Environment

(VROM) and Centre of Environmental Science (CML), Den Haag

and

Leiden,

The

Netherlands,

retrieved

from:

.

PRé Consultants (2012) SimaPro 7.3.3, Amersfoort, NL, retrieved from:

.

Solomon S., Qin D., Manning M., Alley R. B., Berntsen T., Bindoff N.

L., Chen Z., Chidthaisong A., Gregory J. M., Hegerl G. C.,

Heimann M., Hewitson B., Hoskins B. J., Joos F., Jouzel J., Kattsov

V., Lohmann U., Matsuno T., Molina M., Nicholls N., Overpeck J.,

Raga G., Ramaswamy V., Ren J., Rusticucci M., Somerville R.,

Stocker T. F., Whetton P., Wood R. A. and Wratt D. (2007)

Technical Summary. In: Climate Change 2007: The Physical

Science Basis. Contribution of Working Group I to the Fourth

Assessment Report of the Intergovernmental Panel on Climate

Change (IPCC), Cambridge University Press, Cambridge, United

Kingdom and New York, NY, USA.

Stucki M., Büsser S., Itten R., Frischknecht R. and Wallbaum H. (2011)

Comparative Life Cycle Assessment of Geosynthetics versus

Conventional

Construction

Material.

ESU-services

Ltd.

commissioned by European Association for Geosynthetic

Manufacturers (EAGM), Uster and Zürich, CH.