1981

Technical Committee 207 /

Comité technique 207

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

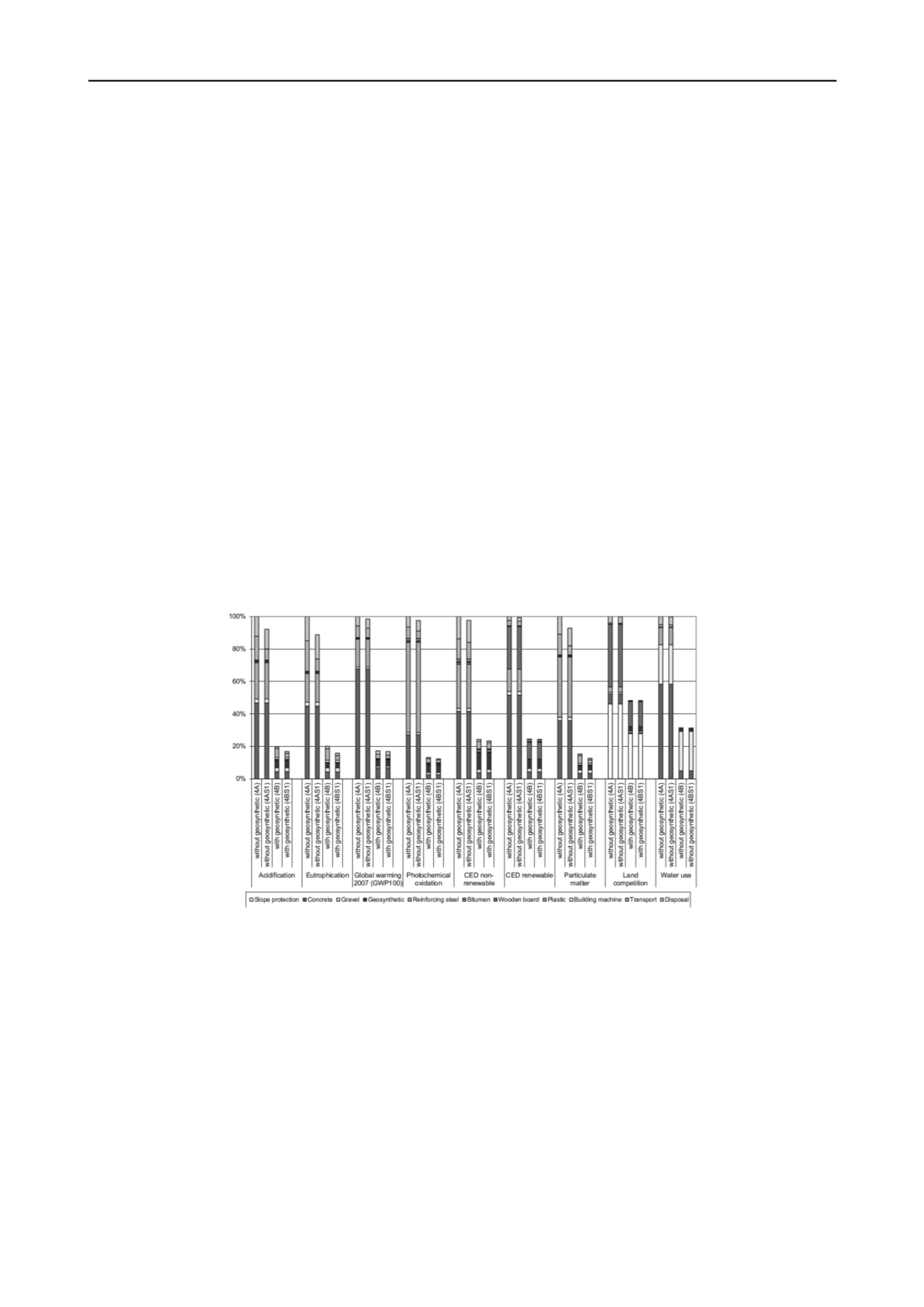

Concrete, the geosynthetic and transportation mostly cause

the highest burdens of the life cycle of the GRRW (4B). The

share of the geogrid to the overall impacts is relatively high

because on one hand several layers, and thus a considerable

amount of geogrid, are required. On the other hand most

materials used in the construction of the slope retention are

available on-site and thus do not cause substantial

environmental impacts (compare Tab. 1). The disposal gains

importance in the categories eutrophication and global

warming. The global warming impacts of disposal are caused

by burning geogrids in waste incineration plants, which leads

to fossil CO

2

emissions. Gravel dominates the water use

indicator and the direct land use of the slope retention wall

during its use is dominating land competition.

of GRRW (4B). The cumulative greenhouse gas emissions

amount to 1.3 t CO

2

-eq in case of the CRRW (4A) and 0.2 t

CO

2

-eq in case of the GRRW (4B). Correspondingly, the

cumulative greenhouse gas emissions of 300 m CRRW (4A)

are 400 t and 70 t in case of GRRW (4B).

The most relevant aspects concerning the environmental

impacts of the life cycle of the CRRW (4A) are concrete,

reinforcing steel, transportation and disposal. This order of

relevance changes depending on the impact category

indicators. The high share of concrete in the global warming

indicator can be explained by the production process of

clinker. During its calcination process geogenic CO

2

emissions arise. Reinforcing steel consists of 63 % primary

steel and 37 % recycled steel. Most environmental impacts of

the reinforcing steel arise from the fuel consumption and the

emissions during the sinter and pig iron production in the

supply chain of the primary steel. Disposal includes the

disposal as well as transports from the construction site to the

disposal site in case the material is not recycled. Impacts of

disposal are dominated by the high amount of concrete which

is landfilled. While direct emissions of landfilling concrete

are negligible, the construction of the landfill and the

transport of concrete to the landfill site are important. The

land competition indicator is strongly influenced by the direct

land use of the slope retention as well as by the wooden board

used in the formworks. Gravel is responsible for a con-

siderable share of the total amount of water used because

substantial amounts of water are needed in gravel production.

The main driving forces for the difference between CRRW

(4A) and GRRW (4B) are the higher amount of concrete used

in CRRW (4A) as well as the use of reinforcing steel, which

additionally leads to higher transport expenditures. With

regard to CED renewable and land competition the wooden

board additionally increases the difference in total impacts

because wood is a renewable resource with a high direct land

occupation. Direct land competition is lower for the GRRW

(4B) because the sprayed concrete lining is thinner than the

CRRW (4A) and the embankment and backfilling area is not

considered as occupied land.

The share of the geosynthetic material on the overall

environmental impacts is between 3 % and 44 % (water use

and CED non-renewable, respectively).

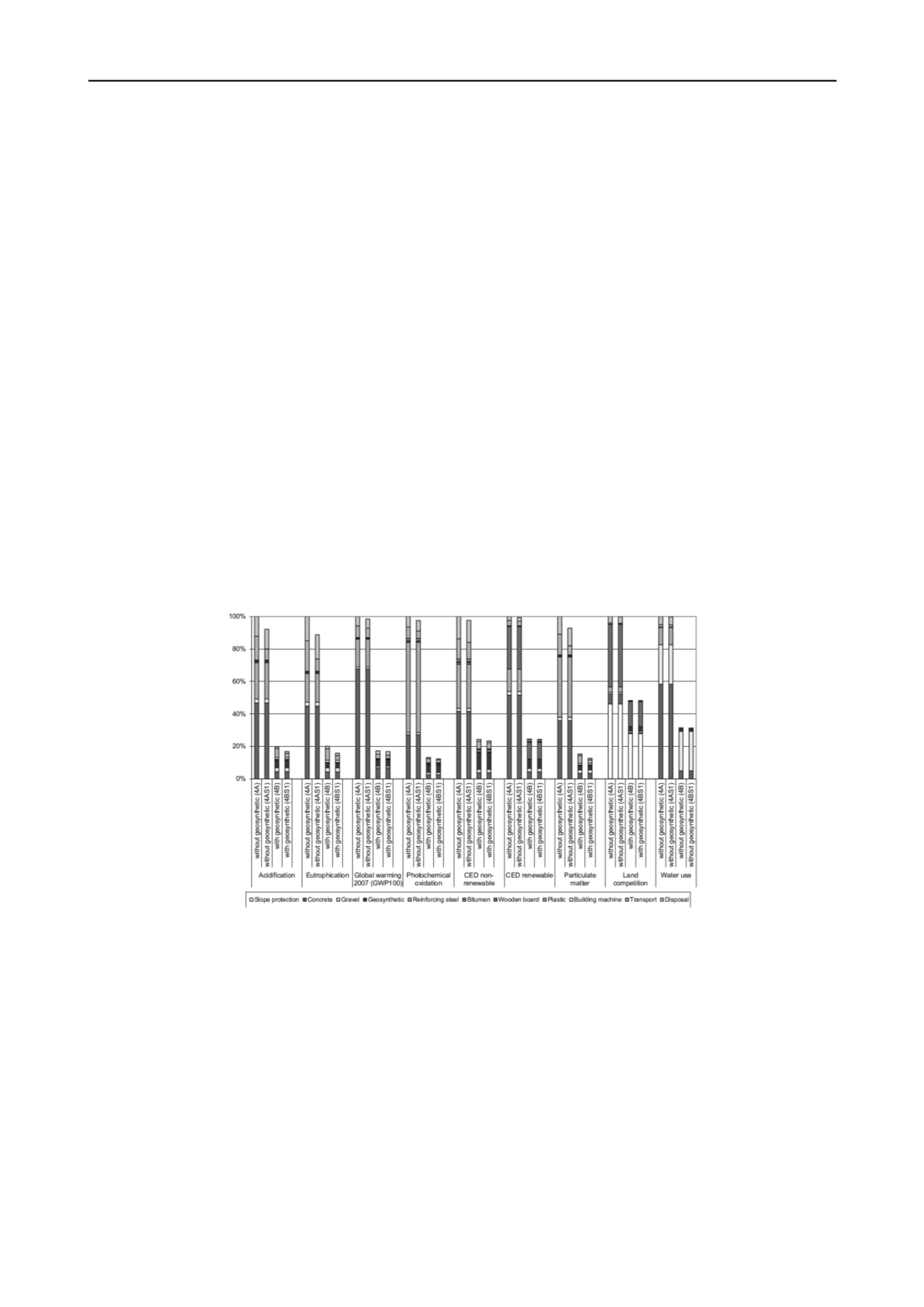

Figure 2. Sensitivity analysis: Environmental impacts of the life cycle of 1 m conventional (4A) and geosynthetic retaining wall (4B). 4AS1 and 4BS1

refer to the sensitivity analysis with a Euro5 lorry transportation. For each indicator, the case with highest environmental impacts is scaled to 100°%.

4.1

Sensitivity analysis

4.2

Contribution Analysis Geosynthetic Production

In a sensitivity analysis, it is analysed how the results of the

slope retention change, when a Euro5 lorry (>32 t) is used for

the transportation of the materials to the construction site

instead of an average European lorry (>16 t).

In this section the environmental impacts of 1 kg geogrid are

evaluated. The life cycle includes the provision and use of

raw materials, working materials, energy carriers, infrastruc-

ture and disposal processes. The category geosynthetic in Fig.

3 comprises the direct burdens of the geosynthetic production.

This includes land occupied to produce the geosynthetic as

well as process emissions (e.g. NMVOC, particulate and

COD emissions) from the production process but not

emissions from electricity and fuel combustion which are

displayed separately. The environmental impacts of the

geogrid are shown in Fig. 3. The cumulative greenhouse gas

emissions amount to 3.4 kg CO

2

-eq per kg.

Fig. 2 reveals that if a Euro5 lorry with lower exhaust

emissions is used for the transportation, the environmental

impacts of the GRRW (4BS1) are reduced between 0.1 % and

22.8 % (land competition and eutrophication respectively),

whereas the environmental impacts of the CRRW (4AS1) are

decreased between 0.2 % and 13.2 % (land competition and

eutrophication respectively). The use of a Euro5 lorry leads

among others to lower NO

X

emissions, which influences

eutrophication. Land competition is obviously not influenced

much by using another type of lorry.

Environmental impacts are mostly dominated by the raw

material provision and electricity consumption. Raw material