1989

Technical Committee 207 /

Comité technique 207

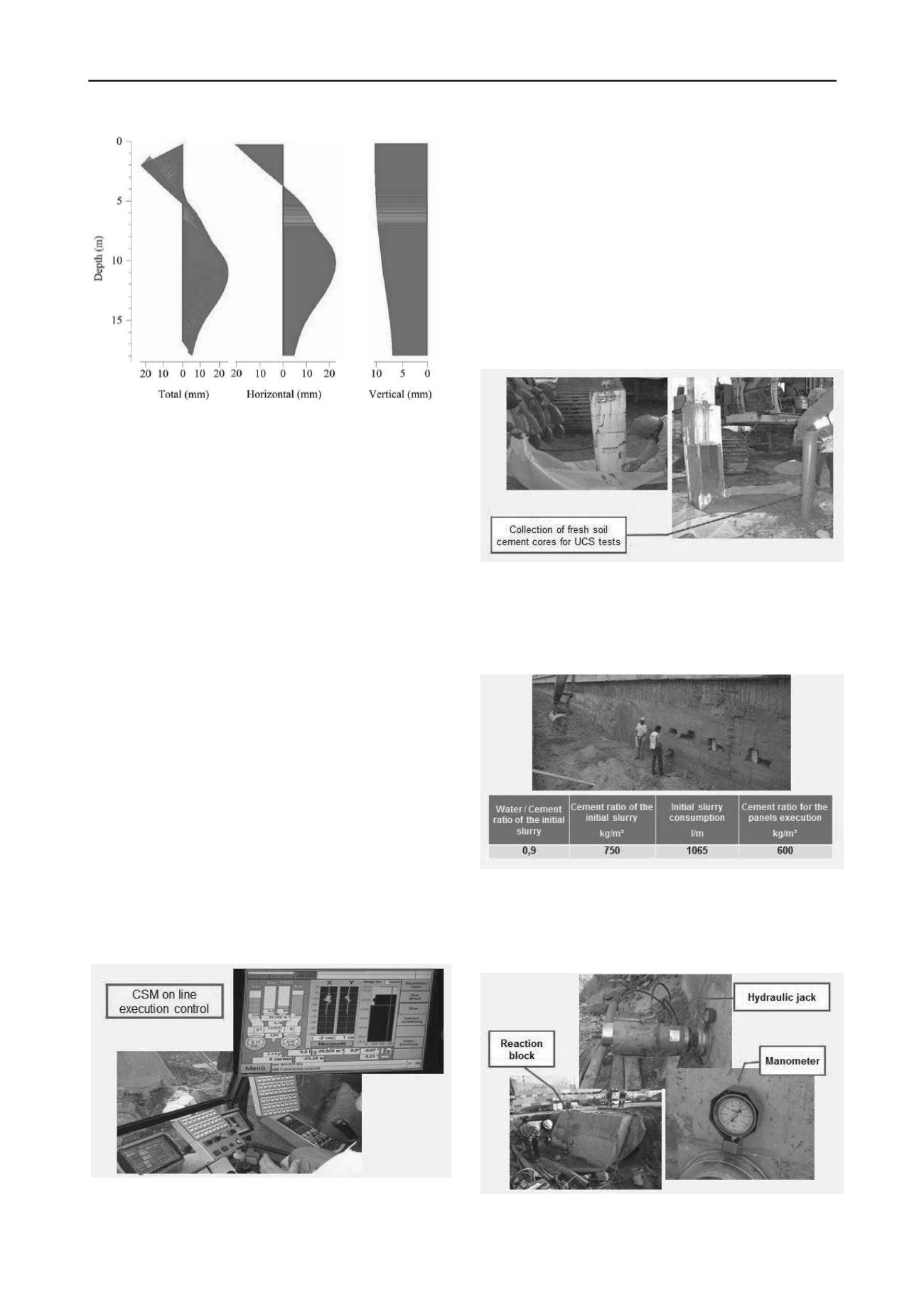

Figure 4. Displacement diagrams.

For the verification of the ultimate limit states was assumed

a simplified approach. Thus, it was considered that the strength

capacity is the individual combination of the strength resistance

of the CSM panels, the IPE270 profiles and the reinforced

concrete lining wall.

Summarising the main results obtained are the following:

- M

Rd

(resistant bending moment) = 167 kNm/m > 1.5

M

ed

(maximum acting bending moment) = 119 kNm/m;

- V

Rd

(resistant shear force) = 251 kN/m > 1.5 V

Ed

(maximum acting shear force) = 207 kN/m;

-

Rd

(resistant compression stress of CSM) = 2 MPa

(with FS=2) > 1.5

Ed

(maximum acting normal stress)

= 1.1 MPa;

- S

H

(maximum horizontal displacement) = 22.7 mm at

about 10m depth.

Based in these results the following design criteria were

established: take into account the resistance and stiffness of

both the steel profiles and the reinforced concrete lining

wall. The contribution of the CSM panels was considered in

order to protect and confine the steel profiles (exploration

phase) and to perform as preliminary ground improvement,

allowing the execution of the excavation works without any

restriction, in each level.

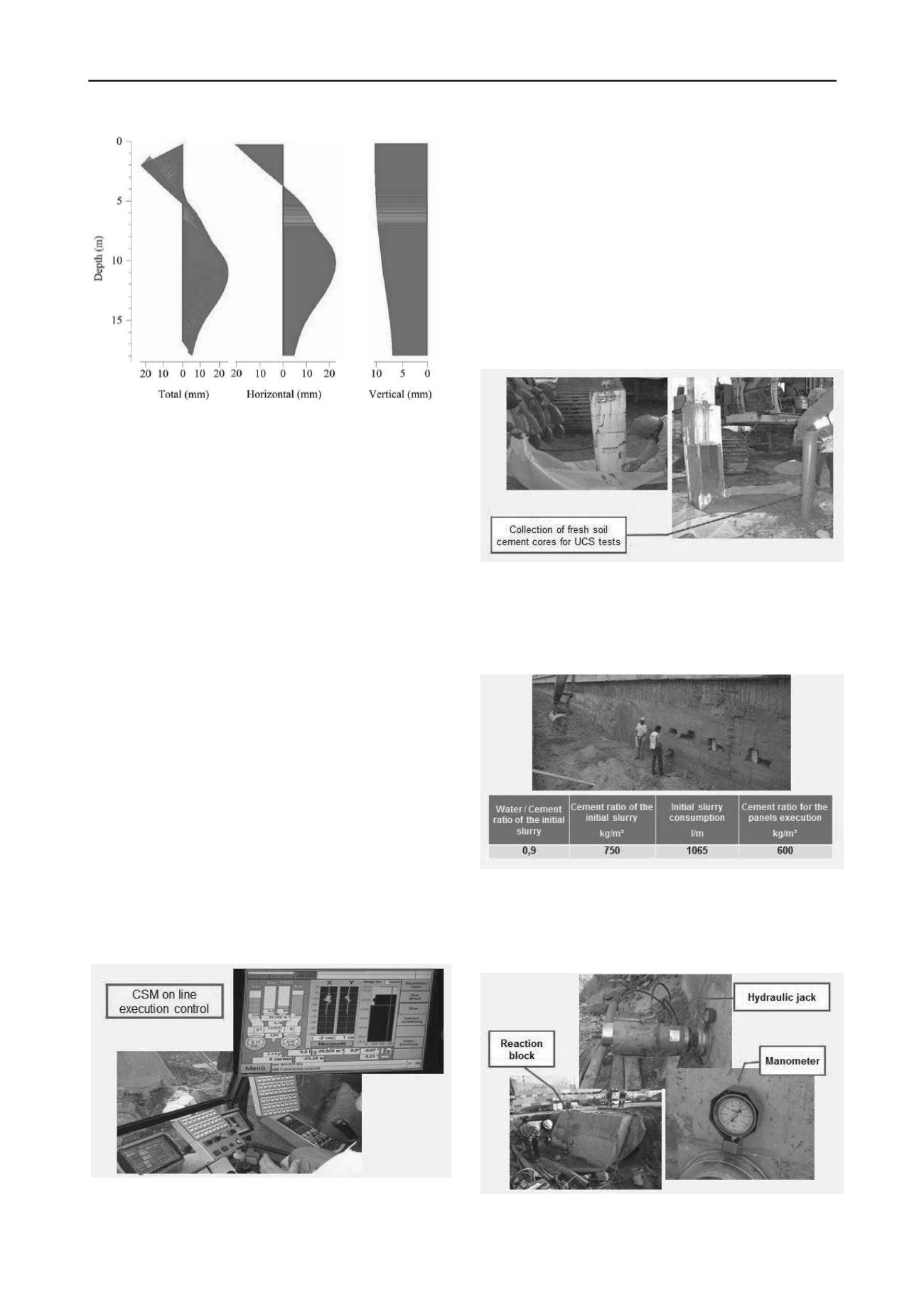

4 QUALITY CONTROL / QUALITY ASSURANCE

4.1

Control of production parameters

One of the major issues of the CSM technology is the high

quality control and quality assurance (QC/QA), allowing on real

time the monitoring and correction of important parameters,

such as: depth, inclination, speed of mixing tools, pressure

(ground and binder slurry) on cutter wheels, rate and total

volume of pumped slurry (Figure 5).

Figure 5. CSM on line execution control

.

4.2

Control of mechanical soil-cement properties

The execution control is complemented by a tight quality

control and quality assurance, allowing the confirmation of both

the main resistance, homogeneity and deformability of the soil-

cement (soil–binder) parameters. For this purpose, samples

from fresh material (before on suitability tested panels and

during construction) and cores from the executed panels (after a

certain curing age ranging from 7 to 28 days) were collected in

order to access the material homogeneity, as well as to perform

laboratorial tests with different ages, mainly unconfined

compression strength (UCS) and Modulus (Es50 – secant

modulus at 50% of maximum stress of UCS). The results

obtained confirm an UCS minimal of 4MPa and a Es50 not

lesser than 1GPa, satisfying the design criteria (Figure 6).

Figure 6. Collection of soil - cement fresh cores

.

Taking into account the results of the UCS load tests, mainly

on the suitability test panels, the following parameters were

adopted for the execution of the CSM panels are presented on

Figure 7.

Figure 7. Adopted values for the CSM panels execution parameters

.

Regarding the QC/QA of the solution, it should also be

pointed out the execution of suitability and reception tests for all

the permanent ground anchors, allowing the optimization of the

anchors grout body length (Figures 8 and 9).

\

Figure 8. Permanent ground anchor suitability test

.