1980

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

strengths. Retaining walls can be reinforced with concrete or

geogrid made of geosynthetics.

The functional unit is defined as the construction and

disposal of 1 m slope retention with a 3 meters high wall,

referring to a standard cross-section. Thus, the functional unit

is independent of the length of the wall.

Polyethylene and PET granules are used as basic material of

the geogrid. The geogrid has to achieve a long-term strength

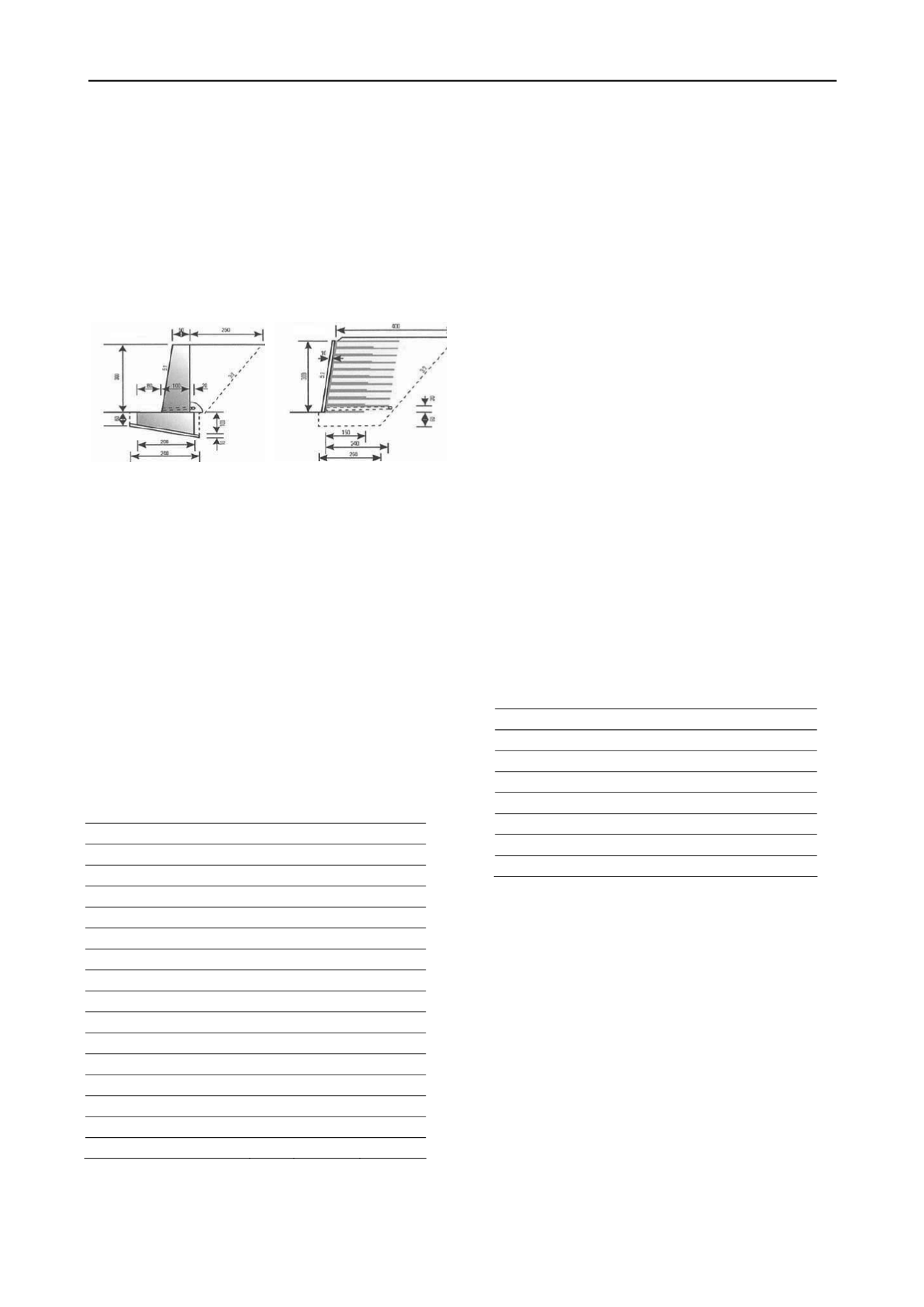

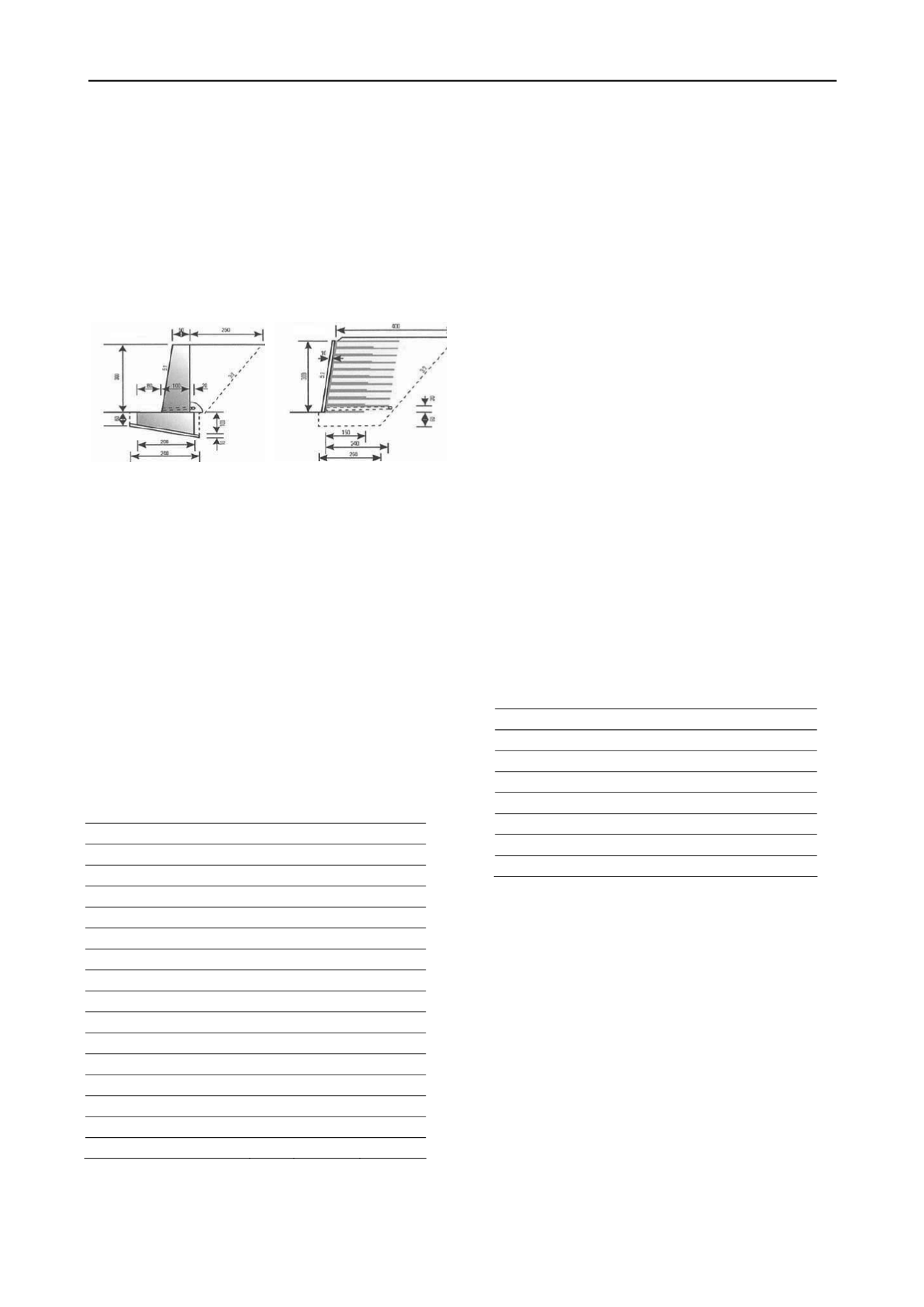

of 14 kN/m. A scheme of both types of retaining walls are

shown in Fig. 1.

Figure 1. Scheme of the concrete reinforced retaining wall (CRRW,

left) and the geosynthetics reinforced retaining wall (GRRW, right)

Some important key figures of the construction of a

reinforced retaining wall are summarized in Tab. 1. The

information refers to one meter of slope retention infra-

structure and a time period of 100 years. Diesel is used in

building machines for the excavation of the foundation and

the compaction of the ground. The NMVOC emissions shown

are released from the bitumen used to seal the concrete wall.

The use of recycled gravel is not considered, since usually no

onsite recycled gravel with specific properties is available

when building reinforced retaining wall for the first time.

Tab. 1 shows specific values of the retaining walls for

both alternatives. The material on site is used as fill material,

wall embankments and cover material in case of a GRRW. A

drainage layer made of gravel with a thickness of at least 30

cm behind the concrete lining is necessary. To be consistent

with the CRRW, a gravel layer thickness of 80 cm is assumed

in both cases. Round gravel is used for drainage purposes .

Table 1. Selected key figures describing the two constructions of one

eter reinforced retaining wall

m

Unit

CRRW

GRRW

Concrete

m

3

/m

1.60

-

Lean mix concrete

m

3

/m

0.24

-

Structural concrete

m

3

/m

2.10

0.31

Reinforcing steel

kg/m

153

-

Gravel

t/m

4.3

4.3

Bitumen

kg/m

2.84

-

Three layered laminated board m

3

/m

0.01

-

Geosynthetic

m

2

/m

-

39.2

Polystyrene foam slab

kg/m

0.25

-

Polyethylene

kg/m

1.74

2.02

Diesel in building machine

MJ/m

11.6

53.9

Transport, lorry

tkm/m 701

265

Transport, freight, rail

tkm/m 33.2

6.9

Land use

m

2

/m

1.0

0.6

NMVOC

g/m

20

-

The difference between the CRRW and GRRW lies in the

amount of concrete, steel and bitumen used, the energy con-

sumption that is related to the slope retention used (material

transportation, excavation etc.), and the use of geosynthetics.

In a sensitivity analysis, it is analysed how the results of the

slope retention change, when a low emission Euro5 lorry

(>32 t) is used for the transportation of the materials to the

construction site instead of an average European lorry (>16 t).

3 MANUFACTURING OF THE GEOGRID

Data about geosynthetic material production are gathered at

the numerous companies participating in the project using

pre-designed questionnaires. The company specific life cycle

inventories are used to establish average life cycle inventories

of geosynthetic material.

The data collected include qualitative information of system

relevant products and processes from the producer,

information from suppliers of the producer (where possible)

as well as data from technical reference documents (e.g.

related studies, product declarations, etc.). Average LCI are

established on the basis of equally weighted averages of the

environmental performance of the products manufactured by

the participating companies.

The primary source of background inventory data used in this

study is the ecoinvent data v2.2 (ecoinvent Centre 2010),

which contain inventory data of many basic materials and

services.In total, data from 5 questionnaires concerning the

production of geosynthetic geogrids used in slope retention

applications are included. The quality of the data received is

considered to be accurate. The level of detail is balanced in a

few cases before modelling an average geosynthetic layer.

Tab. 2 shows important key figures of the production of an

average geosynthetic geogrid

Table 2. Selected key figures referring to the production of 1 kg

eosynthetic layer used in slope retention

g

Unit

Value

Raw materials

kg/kg

1.02

Water

kg/kg

0.86

Lubricating oil

kg/kg

7.30*10

-5

Electricity

kWh/kg

0.73

Thermal energy

MJ/kg

1.24

Fuel for forklifts

MJ/kg

0.13

Building hall

m

2

/kg

6.32*10

-6

4 LIFE CYCLE IMPACT ASSESSMENT

In this section the environmental impacts of 1 m slope

retention with a height of 3 m over the full life cycle are

evaluated. The life cycle includes the provision of raw

materials as well as the construction and disposal phases.

In Fig. 2 the environmental impacts over the full life cycle of

the slope retention are shown. The environmental impacts of

the case with the highest environmental impacts are scaled to

100 %. The total impacts are divided into the sections wall,

raw materials (concrete, gravel, geosynthetic layers,

reinforcing steel, bitumen, wooden board), building machine

(construction requirements), transports (of raw materials to

construction site) and disposal of the wall (includes transports

from the construction site to the disposal site and impacts of

the disposal of the different materials).

The GRRW (4B) causes lower environmental impacts

compared to the CRRW (4A) in all impact categories

considered. The non-renewable cumulative energy demand of

the construction and disposal of 1 meter CRRW (4A) with a

height of 3 meters is 12’700 MJ-eq and 3’100 MJ-eq in case