1961

Technical Committee 207 /

Comité technique 207

predictions (Damians et al. 2013). This value was adopted in the

current study.

3.1.2

Reinforcement loads

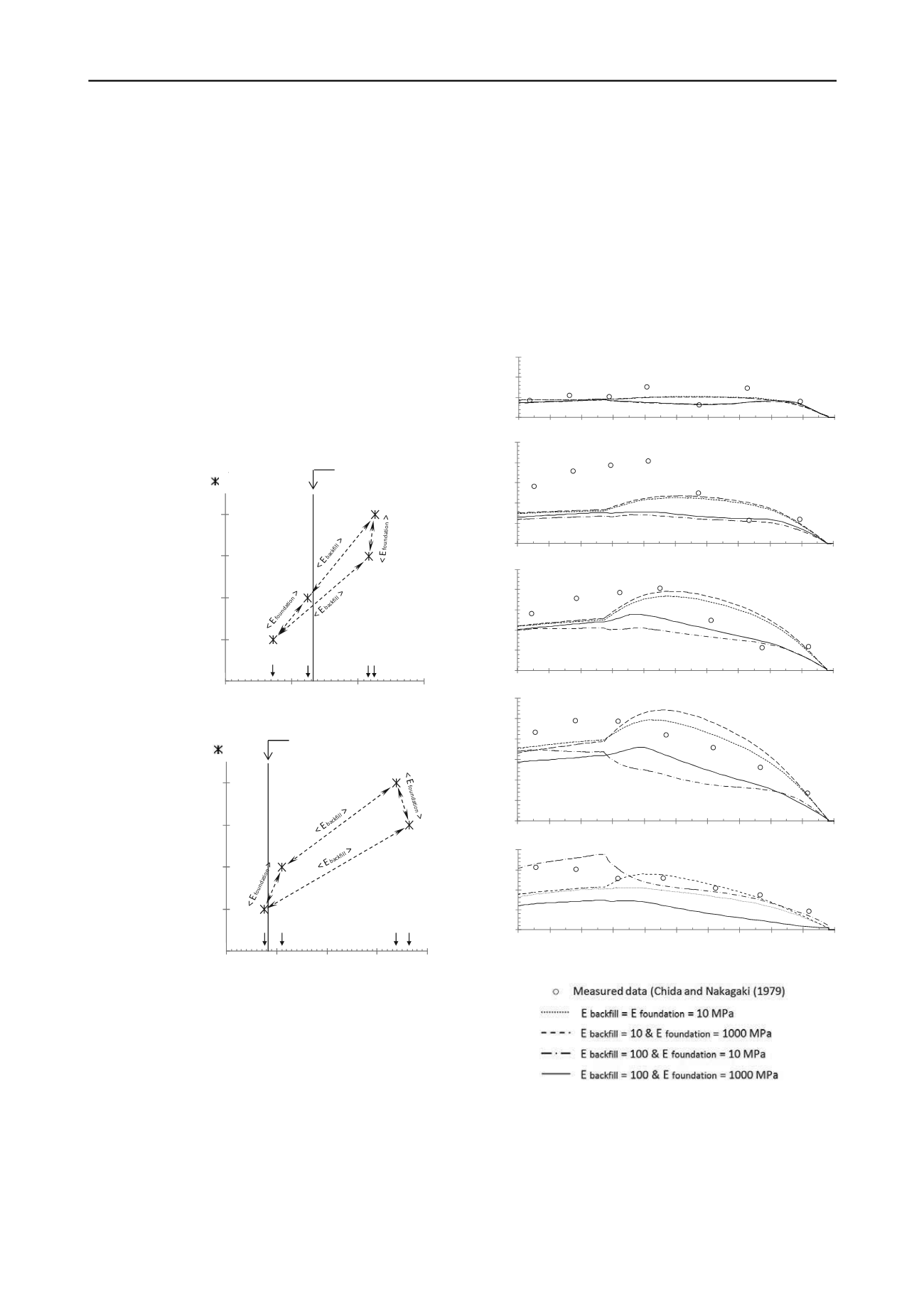

In Figure 3 are shown the results of the reinforcement tensile

loads obtained from numerical modelling and comparison with

measured data for selected strips at different elevations. The

reinforcement length considered in this study is 0.6 – 0.7 times

the total wall height. Steel strips with lengths from 4.0 to 5.0 m

were used in the reference case study, so all locations along any

reinforcement layer are normalized with the respect to the layer

length.

The presented results show good agreement between the

numerical model results and measured data. The backfill-

foundation stiffness combination results give different tensile-

load distributions in the reinforcement layers. The effect of the

less-compacted soil near the facing can be clearly detected with

the discontinuity at a normalized distance from 0 to 0.25.

a) R

i

= 0.3

b) R

i

= 0.6

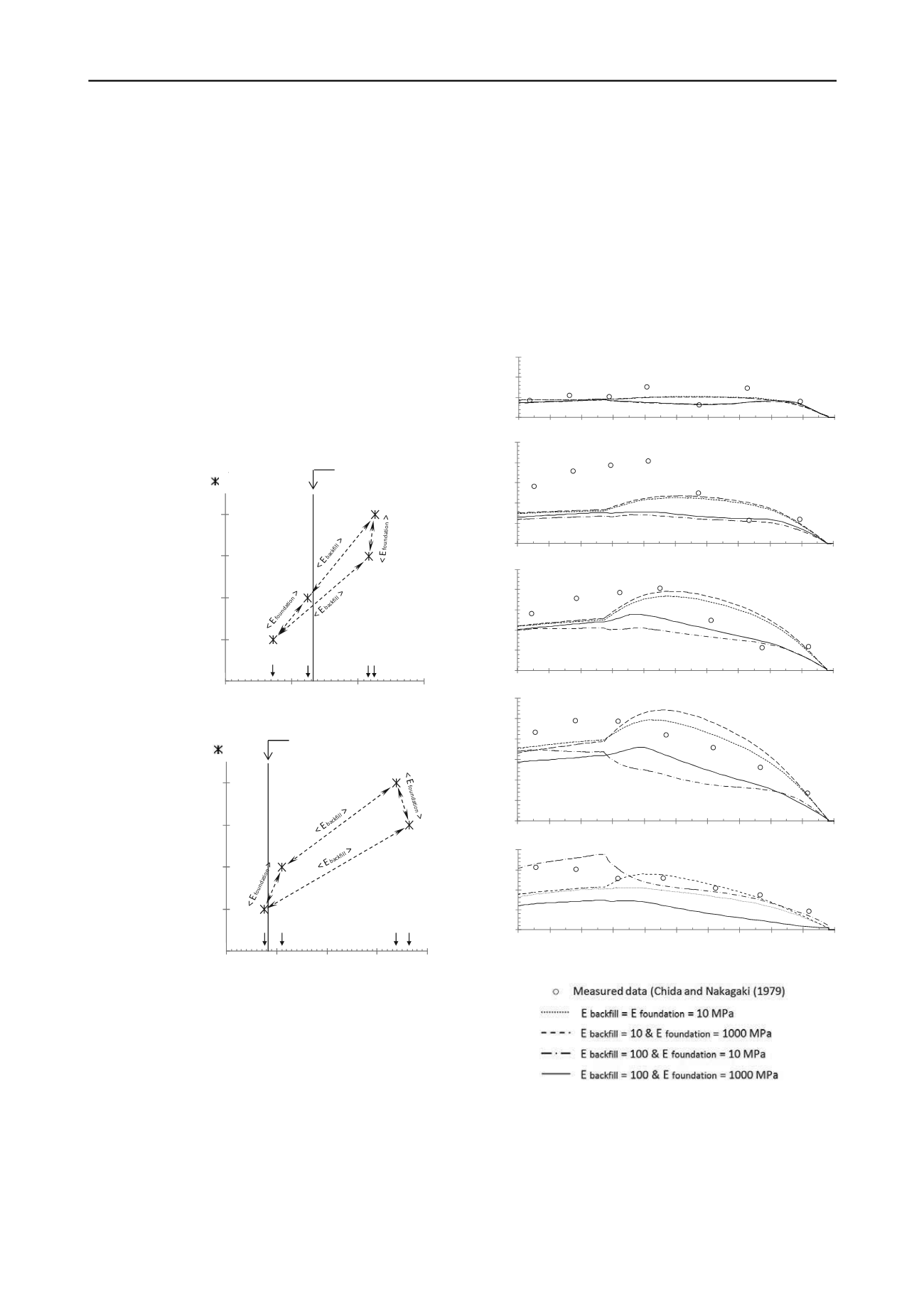

Figure 2. Total vertical loads under the facing assuming soil-facing

interface reduction factor R

i

= 0.3 (a), and R

i

= 0.6 (b)

3.2

Influence of vertical facing stiffness

As noted earlier, the vertical facing stiffness was modified by

changing the number of horizontal joints along the facing height

of the wall. The reported case (base-case) had three horizontal

joins (four panels of 1.5 m-height). Three other cases were

considered to investigate the effect of the vertical facing

stiffness (see Figure 4).

Figure 5 shows the numerical model reinforcement tensile-

loads with respect to the number of horizontal joints. The values

correspond to the maximum load (T

maximum

) of all the

reinforcement strips, its related strip, and the normalized

distance of T

max

to the facing in the strip. Reported values

obtained from Chida and Nakagaki (1979) are also shown.

First, it can be noted that there is little difference in the

predicted T

max

value with respect to the backfill and foundation

stiffness combinations (less than 4 kN/m in the case with more

divergence, i.e. E

backfill

= 100 MPa and E

foundation

=10 MPa

combination). All the T

max

values (numerical and measured) are

located at the bottom zone of the wall (all at the layer located at

1.13 m, except the numerical case with E

backfill

= 100 MPa and

E

foundation

=10 MPa). With respect to their location in the

reinforcement (normalized distance from the facing), all the

T

max

values are located between 0.3 and 0.5.

0

5

10

15

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

1

0

5

10

15

20

25

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

1

0

5

10

15

20

25

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

1

0

5

10

15

20

25

30

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Figure 3. Tensile-load distribution of the wall reinforcements at the end

of construction. (Normalized distance = distance to the facing of a stress

i-point / total length of the reinforcement)

0

1

2

3

4

5

40

50

60

70

Vertical facing load (kN/m)

E

backfill

=

10 MPa

&

E

foundation

=

10 MPa

E

backfill

=

10 MPa

&

E

foundation

=

1000 MPa

E

backfill

=

100 MPa

&

E

foundation

=

1000 MPa

E

backfill

=

100 MPa

&

E

foundation

=

10 MPa

Measuredvalue

(Chida & Nakagaki 1979)

Numerical‐model cases

( )

0

1

2

3

4

5

45

55

65

75

85

Vertical facing load (kN/m)

E

backfill

=

10 MPa

&

E

foundation

=

10 MPa

E

backfill

=

10 MPa

&

E

foundation

=

1000 MPa

E

backfill

= 100 MPa

&

E

foundation

=

1000 MPa

E

backfill

=

100 MPa

&

E

foundation

=

10 MPa

Measuredvalue

(Chida & Nakagaki 1979)

Numerical‐model cases

( )

1

0

5

10

15

20

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Normalized distance to the facing

1

Reinforcement tensile loads (kN/m)

Strip location:

h = 4.94 m (layer 7)

h = 3.42 m (layer 5)

h = 1.9 m (layer 3)

h = 1.13 m (layer 2)

h = 0.38 m (layer 1)