1969

Technical Committee 207 /

Comité technique 207

gravel pool, proposed in the preliminary design, uplift loads are

proposed to be taken by tension piles under the foundation.

As described in the previous sections, the site is located in a

densely populated urban zone and there are important

neighboring infrastructures around the plot. In order to

minimize the lateral displacements to be realized during

excavation implication of the proposed top down procedure was

very effective and superior compare to strutted excavation.

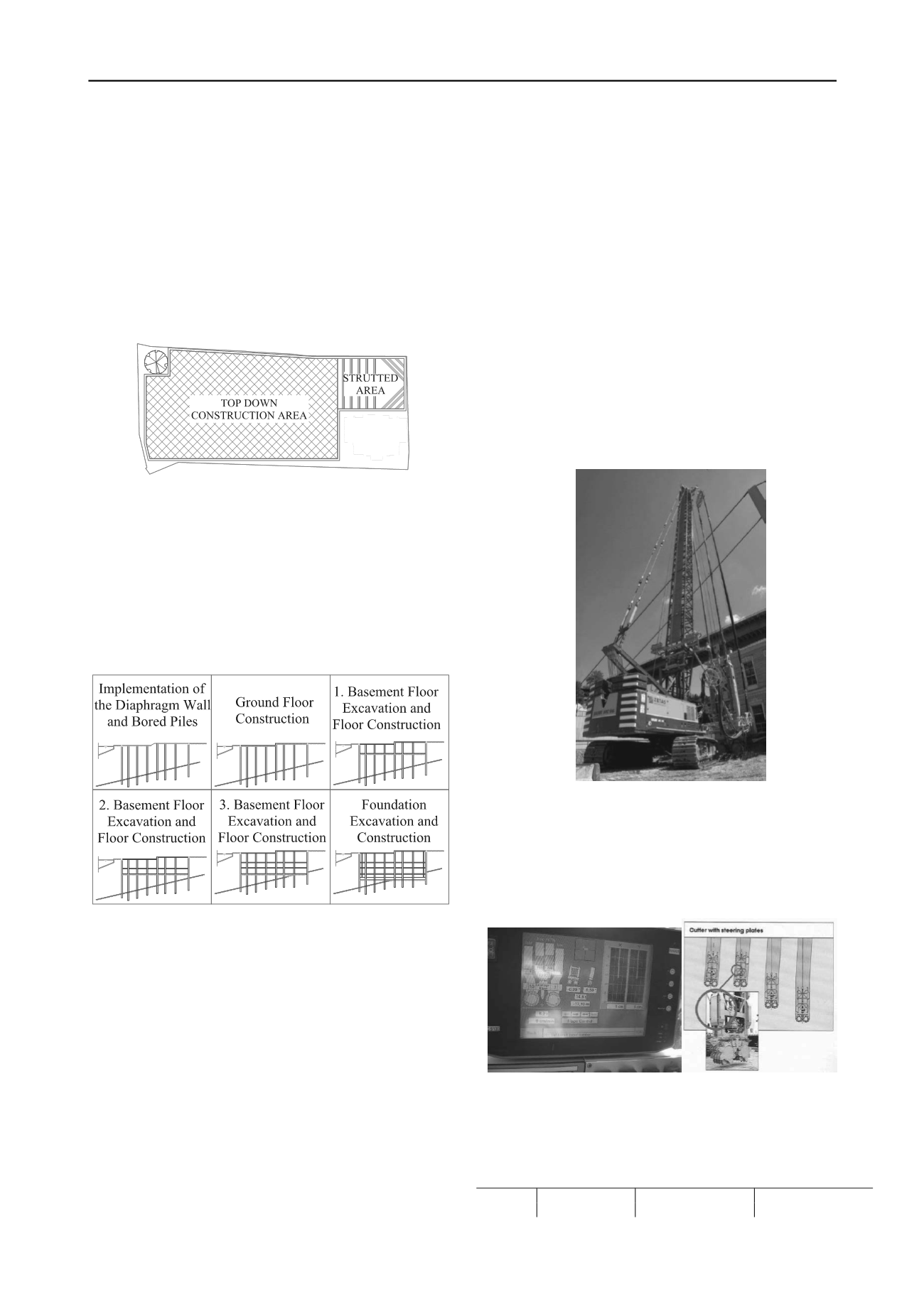

In the proposed top down method permanent diaphragm

walls and piles are to be constructed prior to excavation works.

Later ground level r. c. floor will be constructed except the part

behind the Hatice Sultan residence (Figure 6).

Figure 6. Top Down Construction Area

Soil under the ground level floor will be excavated phase by

phase until the bottom elevation of foundation. In parallel to

excavation works 1st basement r. c. floor will be constructed.

The part of limited excavation plot behind the Hatice Sultan

Residence will be supported with steel struts to provide space

for ramps which will be used for the transportation of the

excavated material. Top down construction steps will continue

similarly as 2nd basement floor 3rd basement floor and

foundation respectively (Figure 7).

Figure 7. Top Down Construction Steps

Groundwater seepage into the excavation site is evaluated

by seepage analysis and optimum socket length in to the

bedrock is determined as 5.0 m. Also settlements due to the

lowering groundwater table are estimated and found to be less

than 18 mm which is considered as tolerable for the existing

structures.

Bored piles are designed to be used as compression and

tension members depending on the loading conditions.

Therefore, piles which will act as permanent columns of the

underground structure are extended into the bedrock having

minimum socket length of 6.0 m basedon the result of pile

tension test conducted at the site in order to satisfy the most

critical tension loading condition under the uplift forces.

Tension capacity of the piles are estimated and taken into

account against uplift forces.

In the top down construction, floor and foundation

reinforcements will be integrated into the permanent diaphragm

wall and piles with the aid of additional link reinforcements

which are already placed in these elements. Details of these link

reinforcements are given in the next section.

After the top down construction steps the limited area

behind the Hatice Sultan Residence will be constructed with

conventional method from bottom to top in parallel to

dissembling the steel struts. Special water-proofing works will

also be implemented under the foundation and on the

constructive inner wall during the down to top construction

steps.

6 CONSTRUCTION STAGE OF DIAPHRAGM WALLS

At the time of paper submission, diaphragm wall construction

was just completed and preparations have been realized to

initiate the piling works. Therefore only diaphragm wall

construction stage would be covered within the paper.

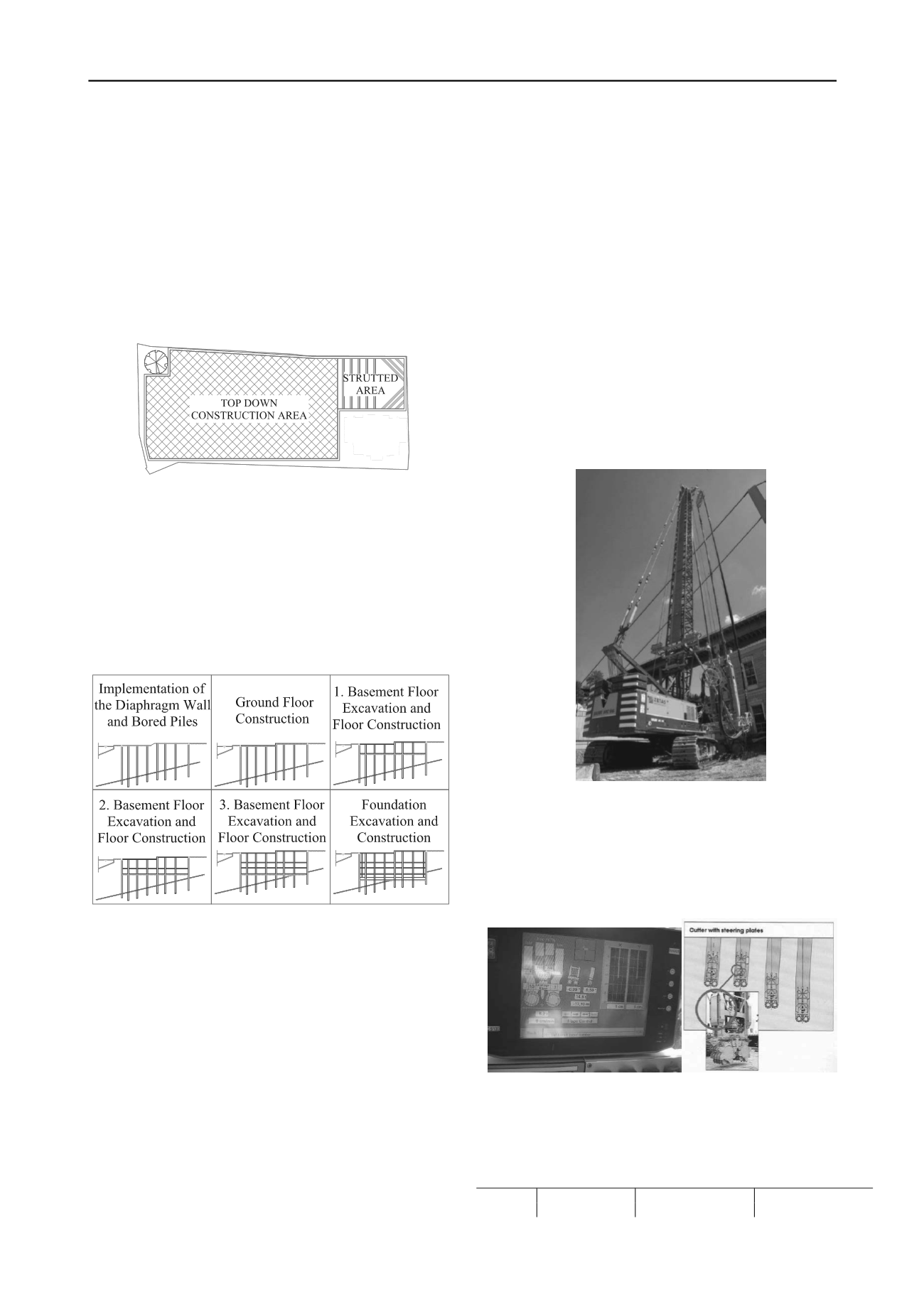

To implement the diaphragm wall in required socket lengths

in the bedrock formation, hydrofraise machine was mobilized

for this project having 81 kNm max. torque per gear box, and 25

rpm max. revolution, with a max cutting depth capacity of 70m

(Figure 8).

Figure 8. Diaphragm Wall Machine, Hydrofraise-Cutter

Another reason of implementing the hydrofraise-cutter

machine was to provide a better verticality control during the

construction of the permanent diaphragm walls. The verticality

was monitored parallel to diaphragm wall excavation and

direction of the cutter controlled with the help of the flaps on

the edges (Figures 9a and 9b).

Figures 9a and 9b. Verticality Control System

During the soil investigations encountered maximum UCS

values of the bedrock are given at the Table 2 below.

Table 2. Unconfined Compression Strength (UCS) values- Mpa

Intrusive Dyke

Sandstone

Shale Sandstone

Min.

Max.

Min.

Max.

Min.

Max.

UCS

Value

0.7

65

3.6

160

1.0

67