845

An elastic-viscous-plastic modeling of time-dependent behaviors of

overconsolidated clays

Un modèle élasto-visco-plastique pour les argiles surconsolidés

Yao Y.P., Kong L.M.

School of Transportation Science and Engineering, Beihang University

ABSTRACT: The instant normal compression line is proposed by analyzing the existing theories and experimental results. Based on

the creep law, the relationship between the aging time and the overconsolidation parameter is built. With the reloading equation of the

UH model used to calculate the instant compression deformation, a one-dimensional stress-strain-time relationship is proposed.

Furthermore, the characteristic rate that is a function of the overconsolidation parameter is defined. Then a three-dimensional elastic-

viscous-plastic constitutive model is suggested by incorporating the equivalent time into the current yield function of the UH model.

The proposed model can describe not only creep, rate effect and other viscous phenomena, but also shear dilatancy, strain softening

and other behaviors of overconsolidated clays. Besides, it needs only one additional parameter (the coefficient of secondary

compression) to consider the creep law compared with the modified Cam-clay model.

RÉSUMÉ : Une ligne de compression normale instantanée est proposée en se basant sur les théories existantes et sur les résultats

expérimentaux. Basée sur la loi de fluage, la relation entre le temps de vieillissement et le paramètre de surconsolidation est établie.

En utilisant l'équation de rechargement du modèle UH pour calculer la déformation de compression instantanée, on propose une

relation contrainte-déformation-temps unidimensionnelle. Par ailleurs, on définit le taux caractéristique qui est fonction du paramètre

de surconsolidation. Ensuite, un modèle tridimensionnel visco-élasto-plastique est proposé en intégrant un temps équivalent dans la

fonction de charge actuelle du modèle UH. Le nouveau modèle peut décrire non seulement l'effet de fluage, l’effet de taux et d'autres

phénomènes visqueux, mais également dilatance, adoucissement et d'autres comportements d'argiles surconsolidés. En outre, il n’y a

besoin que d'un seul paramètre supplémentaire (le coefficient de compression secondaire) dans la loi de fluage par rapport au modèle

Cam-clay modifié.

KEYWORDS: creep, viscoplasticity, stress-strain, overconsolidation, three-dimensional.

1 INTRODUCTION

Viscosity refers to the time-dependency of stress-strain

relationship of clays. The phenomena related to viscosity

include creep and rate effect which would change the

engineering properties of clays and result in such engineering

problems as ground settlements and landslides. Therefore,

numerous studies on viscosity have been conducted and large

numbers of constitutive models have been developed. The

models considering viscosity could be built with the empirical

method, the viscoelastic method or the viscoplastic method.

However, the empirical models are strictly limited to the

specific boundary and loading conditions, and the linear

viscoelastic models are not well valid for the behaviors in the

range of large strains. Hence, more and more studies are

focusing on the viscoplastic models (e.g., Kutter and

Sathialingam 1992, Yin and Graham 2002, Yin et al. 2010).

Nevertheless, most of the models proposed so far are only

applicable to normally consolidated (NC) and slightly

overconsolidated (OC) clays. Although a few viscoplastic

models have been extended to describe viscosity of OC clays

(e.g., Kutter and Sathialingam 1992), they are all complex and

have plethoric parameters. Hence it is necessary to build a new

elastic viscoplastic model for OC clays.

2 UH MODEL

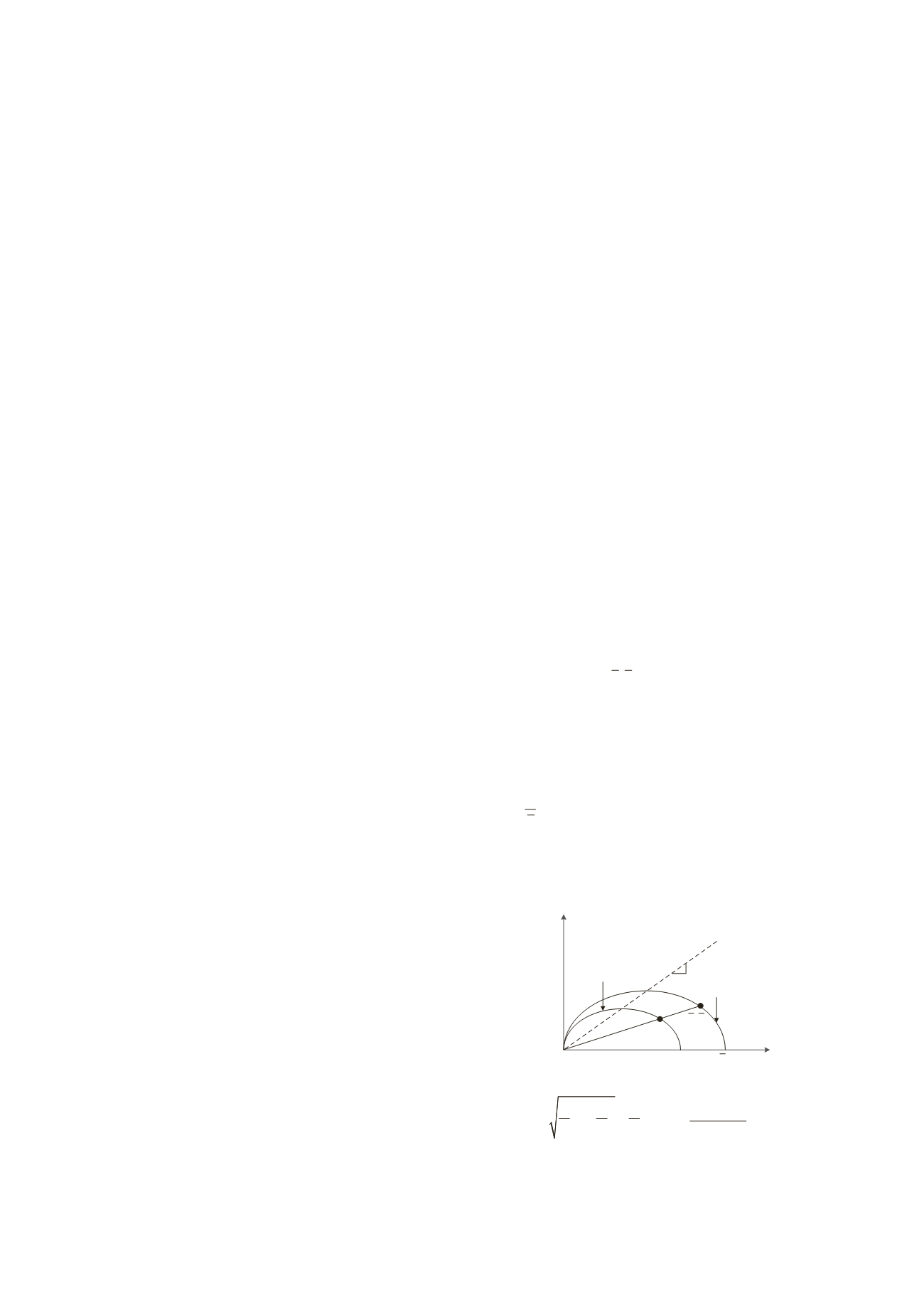

The UH model (Yao et al. 2009) is a constitutive model for OC

clays based on the modified Cam-clay model (MCC). As shown

in Figure 1, there are two yield surfaces in the UH model, i.e.,

the current yield surface and the reference yield surface. The

current yield surface is the one where the current stress point (

p

,

q

) lies.

p

is the mean effective stress and

q

the generalized

deviatoric stress. The reference yield surface passes the

reference stress point

( , )

p q

which is the corresponding point of

(

p

,

q

) at the same stress ratio

η

(

η

=

q

/

p

). The UH model defines

the overconsolidation parameter

R

to reflect the degree of

overconsolidation of clays.

R

is the ratio of the current stress to

its corresponding reference stress. A smaller value of

R

corresponds to a larger OCR (overconsolidation ratio). The

expression of

R

is

p R

p

(1)

In the UH model, the potential failure stress ratio M

f

is

suggested to reflect the strength of OC clays. M

f

is expressed as

follows (Yao et al. 2012).

,

p q

,

p q

x

p

x

p

Figure 1. Current and reference yield surfaces of the UH model.

f

M 6 1

R R R

2

M =

12(3 M)

(2)

where M is the stress ratio at the critical state. Based on the

concept of the potential failure ratio, the UH model changes the