851

Technical Committee 103 /

Comité technique 103

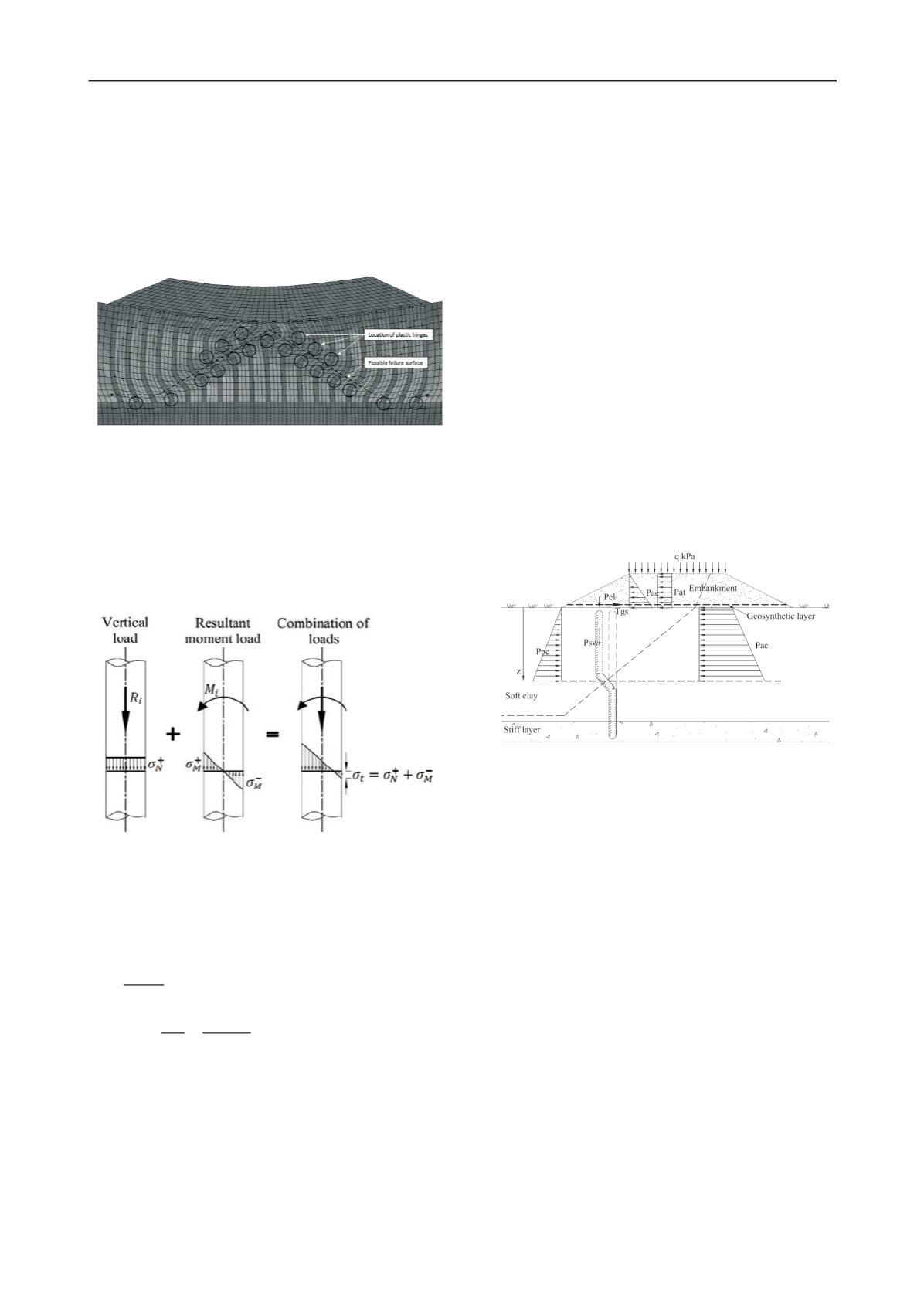

The bending failure mode mainly depends on the tensile

strength of DCM columns. According to Figure 4, axial loads

acting on columns induce compressive stresses within the

column cross section, while the moment load induces both

compressive and tensile stresses. Therefore, stress distribution

within the column cross section may experience tensile stresses,

depending on the magnitude of bending and axial stresses acting

on columns. DCM columns fail when the resultant tensile stress

exceeds the tensile strength of columns.

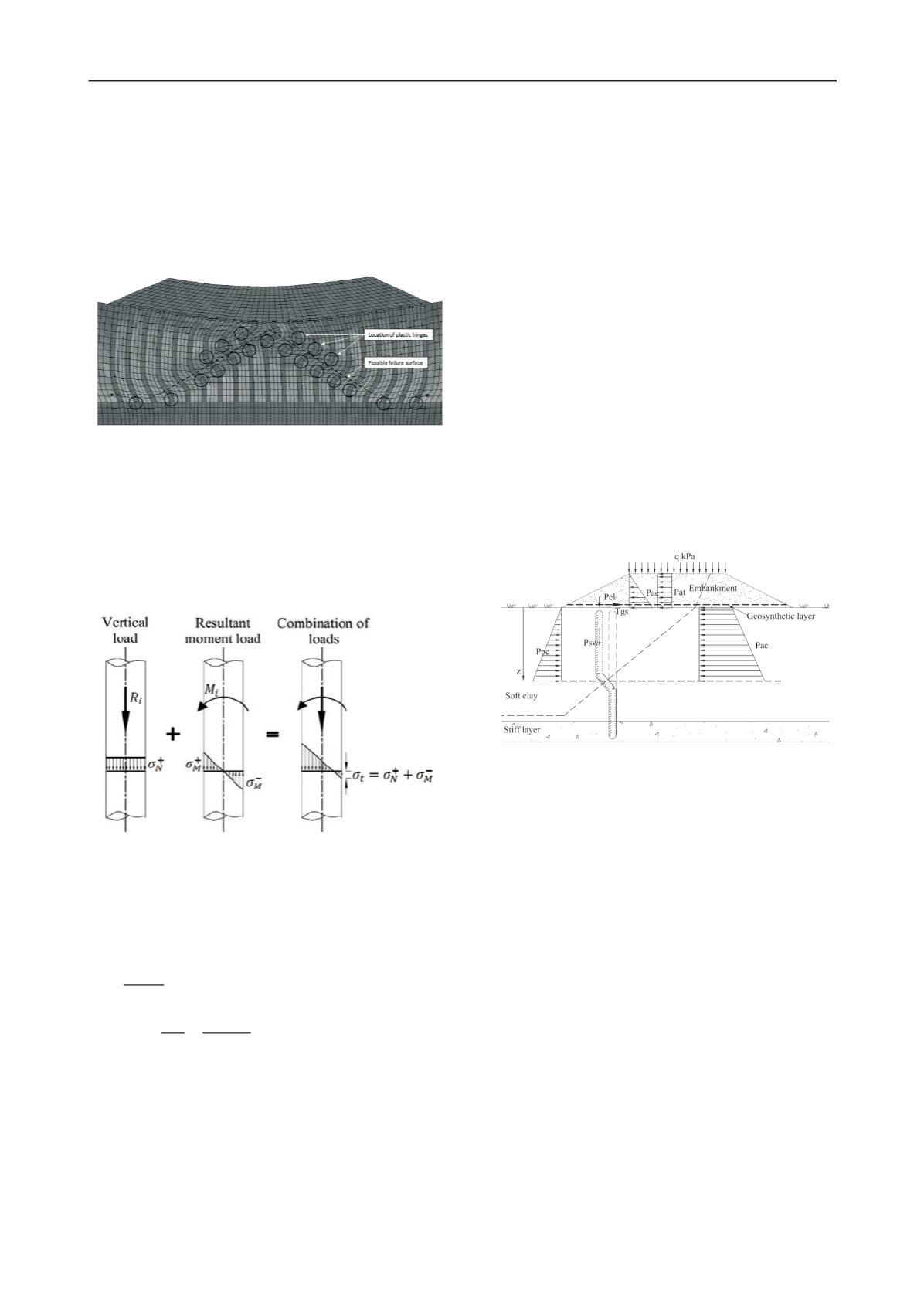

Figure 3. Deformed shape of the finite element model.

According to Broms (2004), the tensile strength of DCM

columns are typically 10 to 20% of the unconfined compressive

strength. However EuroSoilStab (2002) recommended that the

columns created by dry method should not be subjected to

tensile stresses due to the uncertainty in the tensile strength of

DCM columns. Navin (2005) also recommended that the

columns should be designed to satisfy the zero tensile stress

condition at any point across the column cross section.

Figure 4. Induced stress distribution in DCM columns.

To avoid negative stress conditions;

+

> 0

1

and

can be defined as follows.

=

4⁄

2

=

=

=

32⁄

3

where

R

i

is vertical load and

M

i

is resultant moment applied on

columns.

The bending strength or the resistance against bending is

mainly governed by the tensile strength of DCM columns.

Numerical results show that the axial load is low for the

columns closer to the toe of the embankment compared to

middle columns. Therefore bending failure of columns is likely

to initiate closer to the toe of the embankment. The geosynthetic

reinforcement provides a resisting moment against the moment

induced by the lateral earth pressure to reduce the tensile stress

developed within the columns. Therefore, the geosynthetic

reinforcement plays a significant role in resisting the bending

failure of columns. Additionally, closer column spacing, larger

diameter columns, or reinforcing the columns with steel bars or

cages, can be used to withstand the tensile stresses developed

within the DCM columns and thereby to protect columns

against bending failure (Wong and Muttuvel 2011).

Kitazume (2008) proposed a simple stability calculation to

assess embankments over improved grounds against ultimate

bending failure. However, he has not considered the traffic load

over the crest and the tension developed within the geosynthetic

layer. He assumed that the envelope of failure plane of columns

is horizontal. However, the failure plane is an inclined plane as

shown in Figure 3. Therefore, a new stability equation should be

developed against the bending failure considering the inclined

slip surface. In that equation, the active earth pressure due to the

embankment load,

P

ae

,

soft clay,

P

ac

,

and the traffic load,

P

at

,

should be considered as shown in Figure 5 to calculate the

driving moment. Resisting moment should consist of the

contributions from passive earth pressure of the soft clay,

P

pc

,

embankment and traffic load over the columns,

P

el

, self-weight

of columns,

P

sw

, tension in the geosynthetic,

T

gs

, the skin

friction mobilized along the surface of columns and the shear

strength of clay between columns as shown in Figure 5. The

resultant of driving and resisting moments due to loads applied

on columns should not exceed the bending strength of DCM

columns.

Figure 5. Load distribution over columns for embankment in

consideration for the bending failure analysis.

It is important to determine how the gradient of this failure

line varies with geometry and material properties of the

embankment. To achieve this, a detailed parametric study needs

to be carried out before developing analytical equations for the

stability calculation against bending failure.

4.2 Punching failure of fill layers

It is important to investigate the failure modes related to

embankment fill layers such as punching, slip circle or lateral

spreading. However, only punching failure is discussed in this

paper.

The punching failure can be categorized into two types:

local punching failure and overall punching failure. When

column heads are considered, the clay in between columns

settles more than the columns. Therefore, it is possible for

column heads to penetrate into the fill layers, which is known as

the local punching shear failure. If overall punching shear

failure occurs, it is clearly visible at the crest of the

embankment, developing an irregular surface with “humps” at

the column locations and “depressions” in between columns.

Punching failure can be identified from the excessive shear

strains above the columns, and excessive differential settlements

at the base of the embankment in numerical modelling.

To identify these failure modes, two different numerical

analyses were carried out with two different embankment height