313

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1

Shear Strength and Deformation Modulus of Tailing Sands under High Pressures.

Résistance au cisaillement et module de déformation de sables de rejets sous hautes pressions.

Campaña J., Bard E.

ARCADIS Chile

Verdugo R.

CMGI Chile

ABSTRACT: This article discusses the results obtained for 4 different tailing sands from copper mines located in Chile and Peru,

which were subjected to triaxial tests performed in drained and undrained conditions (CID and CIU), applying confining pressures up

to 3 MPa. The evolution of the deformation moduli, static and cyclic shear strength under drained and undrained paths for a wide

range of confining pressure, densities and fines content have been obtained. Also, the tests results have been interpreted, analyzed,

and compared with those reported for natural sands in the international literature, highlighting the differences in the mechanical

behavior resulting from the difference in genesis among these materials

.

RÉSUMÉ : Le comportement mécanique de 4 sables de rejets différents, provenant de mines de cuivre situées au Chili et au Pérou, a

été analysé à l’aide d’une série d’essais triaxiaux effectués en conditions drainées et non drainées (CID et CIU), en appliquant des

pressions de confinement jusqu’à 3 MPa. Les essais, pratiqués sur des échantillons avec différentes densités initiales et contenus de

particules fines, ont permis de suivre l’évolution du module de déformation et de la résistance au cisaillement statique et cyclique,

drainée et non drainée, pour une large gamme de pression de confinement. Ces résultats ont été interprétés, analysés et comparés à

ceux rapportés dans la littérature internationale pour des sables naturels, mettant en évidence les différences dans le comportement

mécanique résultant de la genèse différente de ces matériaux

.

KEYWORDS: tailing sands, high pressure, deformation modulus, copper tailing, triaxial, shear resistance.

1 INTRODUCTION.

Currently, both the important increase of production in the

copper mining industry and the decrease of available space for

the construction of tailing deposits have led to the design of

dam walls having unprecedented heights (above 250 m). This

situation requires that the geotechnical properties of the coarse

sands used for the dam construction be determined adequately

and rigorously. Also, the evolution of the deformation modulus

and shear strength due to changes in the compaction density and

in the fines content, among other characteristics, needs to be

assessed to feed the numerical modeling of these structures,

which is required to predict their behavior in the short and long

term as well as when faced with extreme seismic events. In the

technical literature, there is scarce information about the

evolution of non-drained shear strength as well as about the

cyclic shear stress and deformation modulus of tailing sands,

particularly under high confining pressures.

Results of tests performed on 4 types of cycloned copper

tailings sands, under high confining pressures, with a wide

range of confining pressures, densities, and fines contents are

presented. These tests include: grain size, index properties,

compaction, static triaxial (drained and undrained), cyclic

triaxial, small deformations and resonant column triaxial tests.

2 SANDS TESTED

The sands tested come from 4 copper mining processes (in

operation and projects). The “Arenas Tórtolas” (S1) come from

the Las Tórtolas Tailings Impoundment, from the Los Bronces

Mine (Anglo American Chile); of the remaining samples (S2 to

S4), two correspond to mines in Chile (2) and one in Peru (1).

The main mineral that makes up the sands tested is quartz (45%

to 60%), then sericite / sericite-muscovite (15% to 30%) and

other minerals (Campaña, 2011). The index properties of the

samples tested are summarized in Table 1. All the sands classify

as silty sands (SM), of low plasticity with a PI<7 (Plastic

Index).

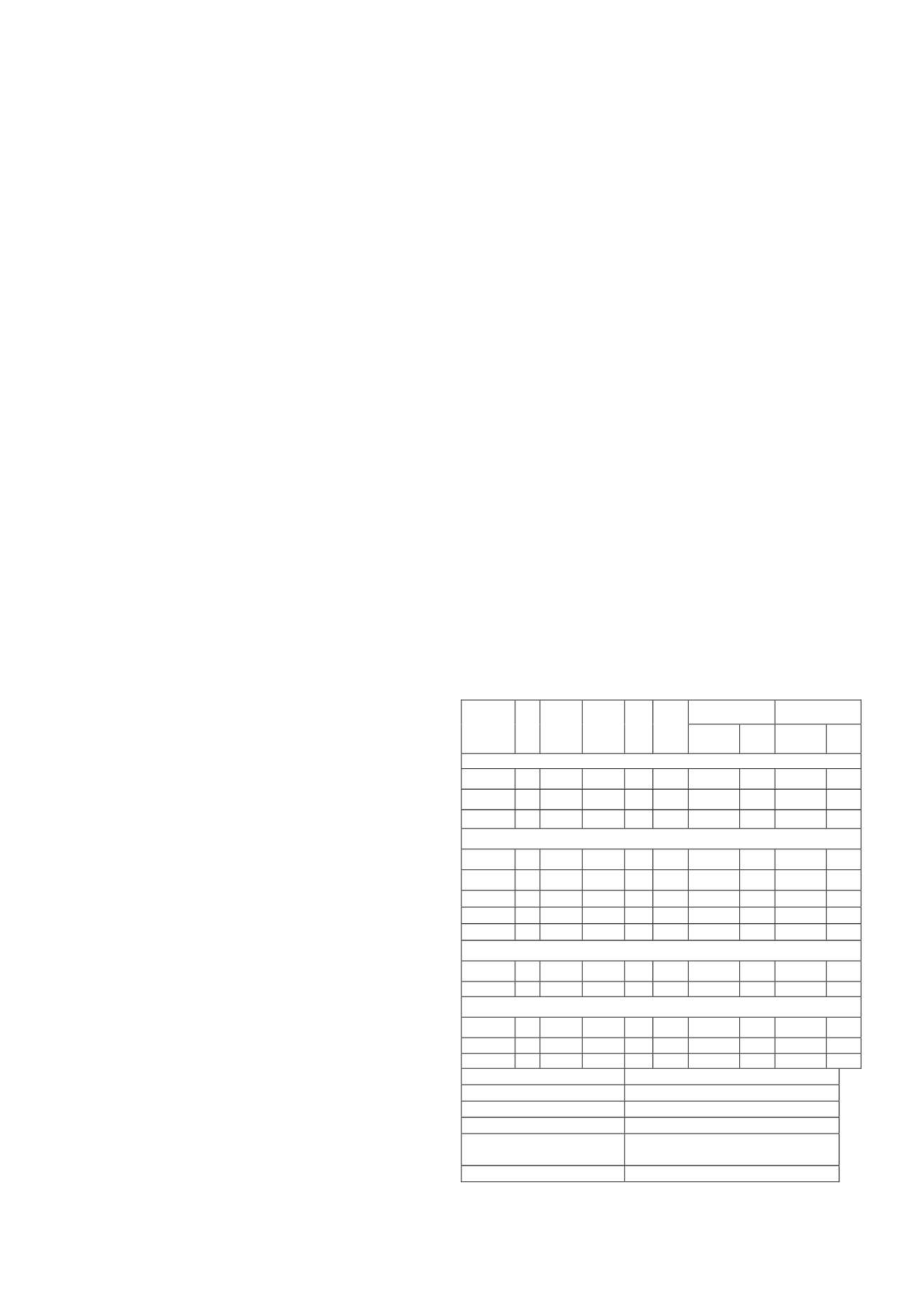

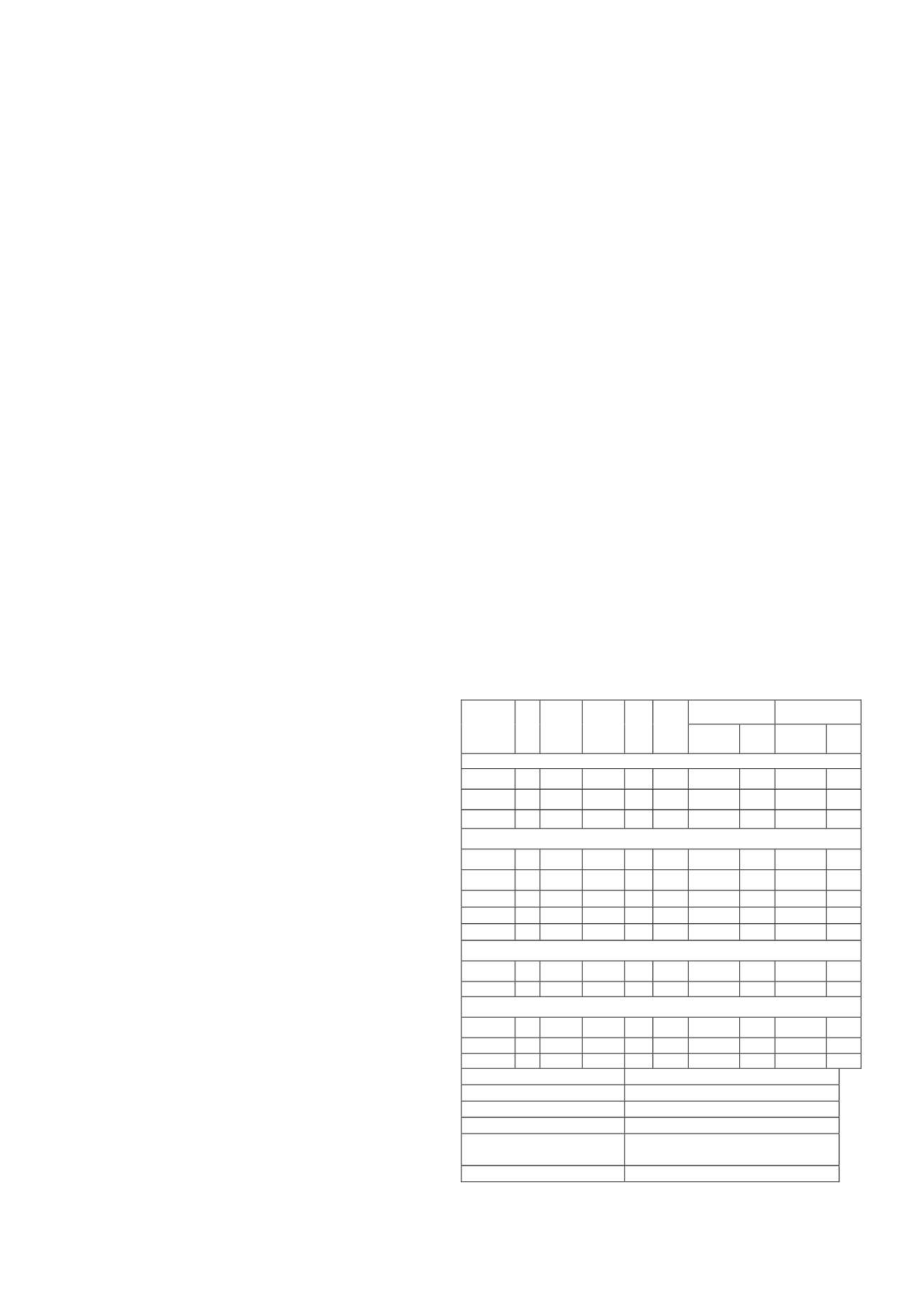

Table 1. Index Properties of Tested Sands (Campaña, 2011)

MP

SP

USCS

Classif.

%

F

e

max

e

min

Cc Cu

MDD

(kN/m

3

)

w

opt

(%)

MDD

(kN/m

3

)

w

opt

(%)

Sand S1 - Las Tórtolas (Gs=2.73)

SM

15 1.100 0.460 1.4 3.3

16.78 14.0 15.89 18.0

SM

18 1.068 0.444 1.5 3.6

16.97 14.0 16.38 16.0

SM

21 1.084 0.414 1.0 4.0

17.36 12.5 16.38 16.0

Sand S2 (Gs=2.67-2.75. Gs average=2.72)

SM

15 1.310 0.647 1.2 1.7

16.68 10.0 15.30 14.0

SM

(§)

15 1.068 0.517

-

-

17.07 12.8

-

-

SM

(§)

18 0.992 0.537

-

-

16.88 13.8

-

-

SM

21 1.331 0.571 1.2 1.8

16.87 11.0 15.99 18.0

SM

Sand S3 (Gs=2.70)

SM

12 0.942 0.525 1.2 4.2

17.46 13.5 16.48 15.5

SM

18 0.956 0.484 3.1 12.9 18.25 11.0 16.77 14.5

Sand S4 (Gs=2.69)

SM

24 0.915 0.406 2.7 165

18.84

8.0

17.36

8.5

SM

20 1.280 0.601 1.2 4.2

16.48 15.0 15.40 18.0

SM

30 1.280 0.592 3.1 12.9 17.85 11.5 16.87 14.0

% F: particles <0,074 mm

MDD: Maximum Dry Density

Gs: Specific gravity

MP: Modified Proctor Test

e

max

: Maximum void ratio

SP: Standar Proctor Test

e

min

: Minimum void ratio

w

opt

: Optimum water content

Cu:

Coefficient

of

uniformity

(§) Tested at low pressures,

’

3

<0.8MPa

Cc: Coefficient of curvature

USCS: Unified Soil Classif. System