311

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

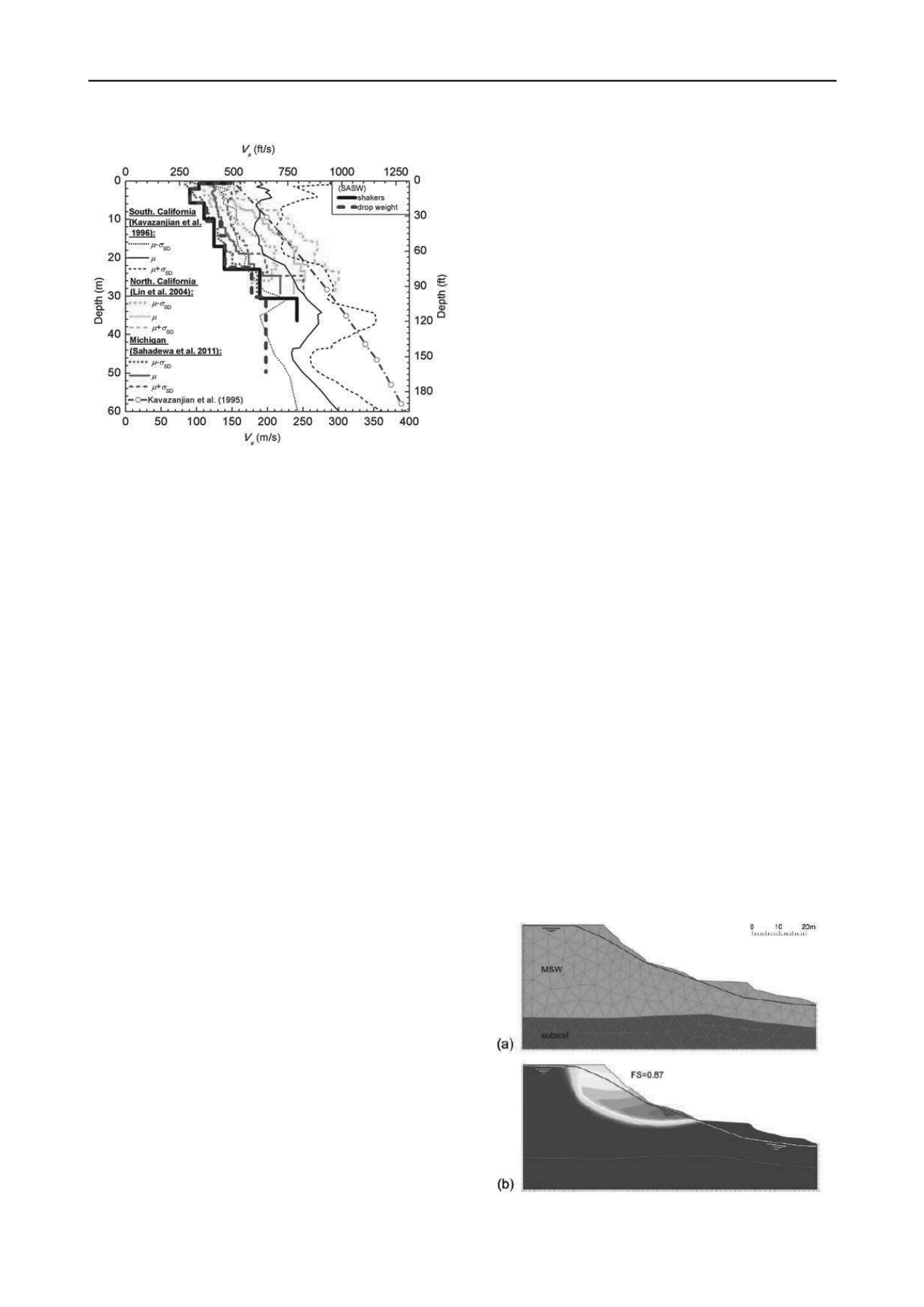

Figure 4. Comparison of V

S0

vs depth profile at Xerolakka landfill with

other published cases of landfills.

5 PROPERTIES OF MUNICIPAL SOLID WASTE

No site specific data was available on the MSW that was

disposed of at the Xerolakka landfill. Thus, for the performance

of the limit equilibrium and finite element stability analyses, the

measured V

S0

was used to guide the selection of MSW

properties. For the performance of the analyses the unit weight,

shear strength, deformation modulus (for the finite element

analyses) and Poisson’s ratio of MSW are required and were

selected as follows:

Unit Weight

: The selection of the MSW unit weight has an

impact on the stability of the waste mass. On the basis of the

available landfill information and the Zekkos et al. (2006)

recommendations, for the 30 m thick waste mass, an average

unit weight value of 12 kN/m

3

was used. This value is also

consistent with the unit weight value used for the design of the

landfill facility (Koronis 1995).

Shear Strength

: The selection of appropriate shear strength

parameters is critical in evaluating the stability of the waste

mass. Bray et al. (2009) recommended a generic MSW shear

strength envelope. The recommended strength envelope was the

mean fit to a large dataset, however, various factors such as

waste composition and unit weight may result in variations from

this envelope. For example, the unit weight has an important

impact on the shear resistance of MSW. As reported by Zekkos

et al. (2010), for waste with the same waste composition, a

reduction in unit weight by 2kN/m

3

results in an approximate

reduction in shear strength by 20%. Considering the absence of

compaction and daily soil cover as well as the particularly low

measured shear wave velocity of the MSW, the shear strength

of the Xerolakka landfill MSW was reduced by 20% from the

shear strength envelope recommended by Bray et al. (2009).

MSW elastic modulus and Poisson’s ratio

: The large-strain

elastic modulus E

ref

is an explicit input parameter in finite

element analysis. The value of E

ref

impacts the calculated

displacements, but does not influence significantly the

calculated factor of safety. In the present study, it was assumed

that the modulus is equal to 1/10 of the small-strain elastic

modulus E

o

, which was calculated from the measured small

strain shear modulus G

o

, whereas the Poisson’s ratio value was

assumed to be equal to 0.1, based on data available in the

literature (Zekkos, 2005).

6 STABILITY ANALYSES

Stability analyses of the Xerolakka landfill slope failure were

performed using both limit equilibrium (Geo-Slope 2007 –

SLOPE/W) and finite element (PLAXIS, 2004) analyses and the

material properties described earlier. Each analysis

methodology has its strengths and limitations. In finite element

analyses, there is no requirement to predefine candidate failure

surfaces; instead, the failure surface with the lowest factor of

safety is identified using the phi-c reduction methodology

(PLAXIS, 2004). Another known advantage of the FEM is its

ability to calculate displacements in every prescribed stage of

calculation as well as its ability to model progressive failure. In

limit equilibrium methodology, the factor of safety for a large

number of failure surfaces is calculated and the one with the

lowest factor of safety is the critical one. For the calculation of

the factor of safety, the Spencer method (Spencer, 1967) is

used. Limit equilibrium methods do not account for the

presence of strain softening materials, since no consideration of

strains or displacements is made.

It is important to note that, in the case of Xerolakka landfill,

it is very difficult to evaluate the actual pore pressure regime

within the waste mass due to the unavailability of field data.

Thus, stability analyses were performed for two cases: complete

absence of leachate table (provided a leachate and gas collection

system was operating properly) and for the case of a high

leachate table resulting from the absence/non operative leachate

and gas collection system. The leachate table used in the

analyses was estimated on the basis of field observations,

namely: 1) the presence of ponding water at the crest of the

landfill (near the waste slide) and 2) observed seepage at the toe

of the waste slide. The high leachate table is intended to account

in a conventional manner for the presence, and possibly flow, of

leachate and more importantly the generation of gas due to

biodegradation. The amount of gas generated can be significant

and for that reason, modern landfill facilities are equipped with

a gas collection system that collects the gas and either combusts

it using a flame or uses it to generate energy. There was no gas

collection system in the active waste disposal area. Gas and

leachate pressures would result in a reduction of the effective

stress in the waste and a subsequent reduction in the factor of

safety.

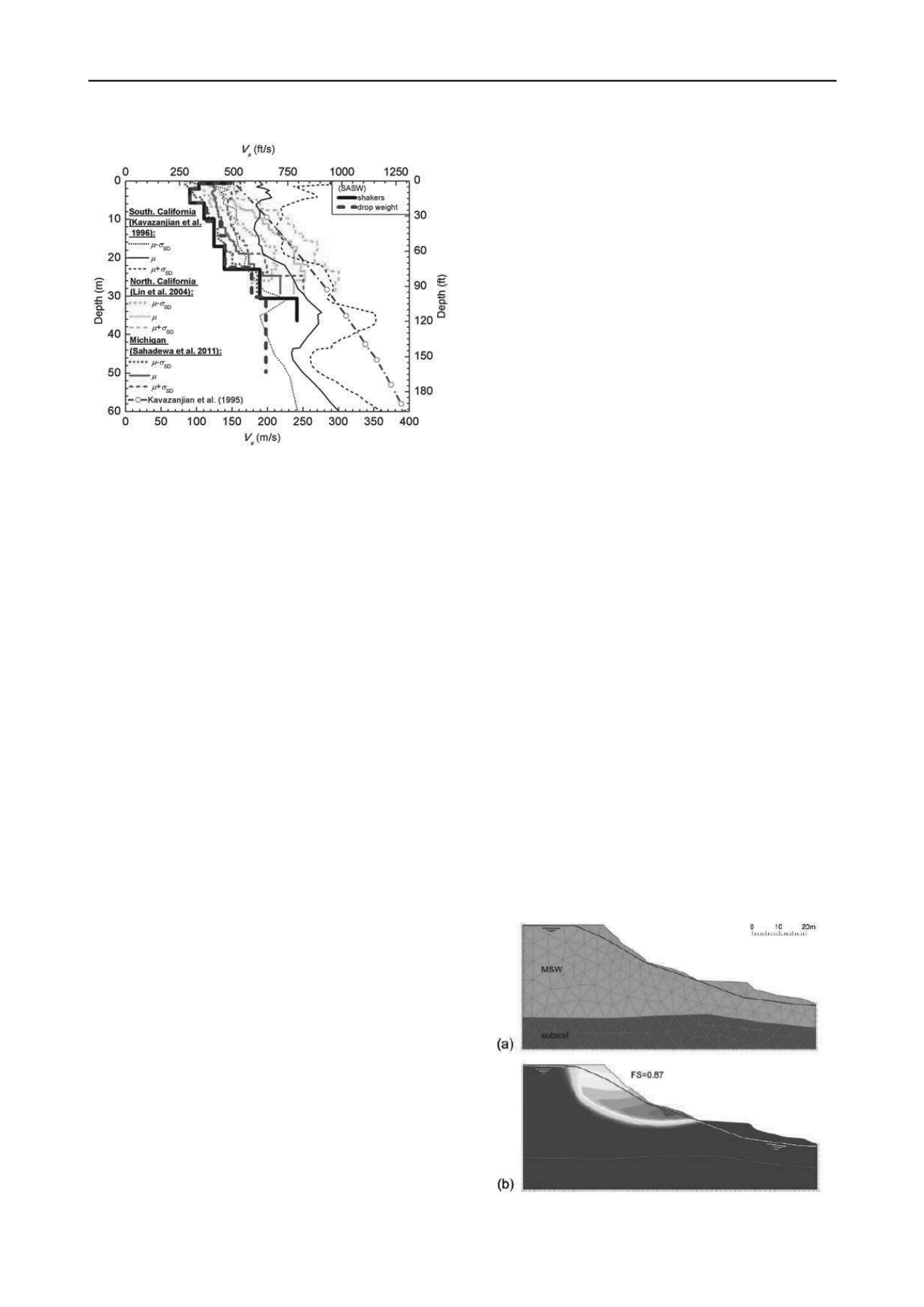

7 RESULTS OF ANALYSES AND DISCUSSION

Analyses were performed for the selected properties and the

cross-section geometry at the location of the failure. The

inclination of the slopes in the upper part of the landfill is as

high as 1.2:1 (horizontal to vertical). In the case of absence of

leachate table and gas pressure (“dry tomb” landfills), the

results of analyses indicate a stable condition with a calculated

factor of safety equal to 1.60, i.e., higher than the 1.50 typically

required. Additional analyses were performed with the assumed

leachate table, as shown in Fig. 5.

Figure 5. Finite element mesh (PLAXIS 8.6) of the critical failure

surface with (a) soil stratigraphy and (b) critical failure surface for the

estimated leachate table.