319

Technical Committee 101 - Session II /

Comité technique 101 - Session II

40 (425 µm) sieve. At this point, the samples were at a water

content much greater than the liquid limit and were therefore

air-dried to reduce the water content. The soil was considered to

be at the desired water content when 23 to 25 blows using a

Casagrande liquid limit cup were required to close the groove

cut in the soil as specified in ASTM D4318-10.

Table 1. Soil index properties.

Soil

Specific

Gravity

LL

PL

PI

Clay-sized

Fraction

Colorado Clay

2.78

42

22

20

23.7

NOVA Clay

2.80

66

28

38

16.8

VBC

2.79

78

26

52

68.9

To perform CD direct shear tests, the test specimens were

formed directly in the direct shear box using a spatula or

“piped” from a pastry bag. Care was taken to form the test

specimens without entrapping air-bubbles. Prior to shearing, the

samples were consolidated under K

o

conditions to vertical

pressures ranging from 24 kPa to 288 kPa. The samples were

then sheared slow enough to allow full dissipation of the pore

pressures generated during shear using the criterion presented in

ASTM D3080-11.

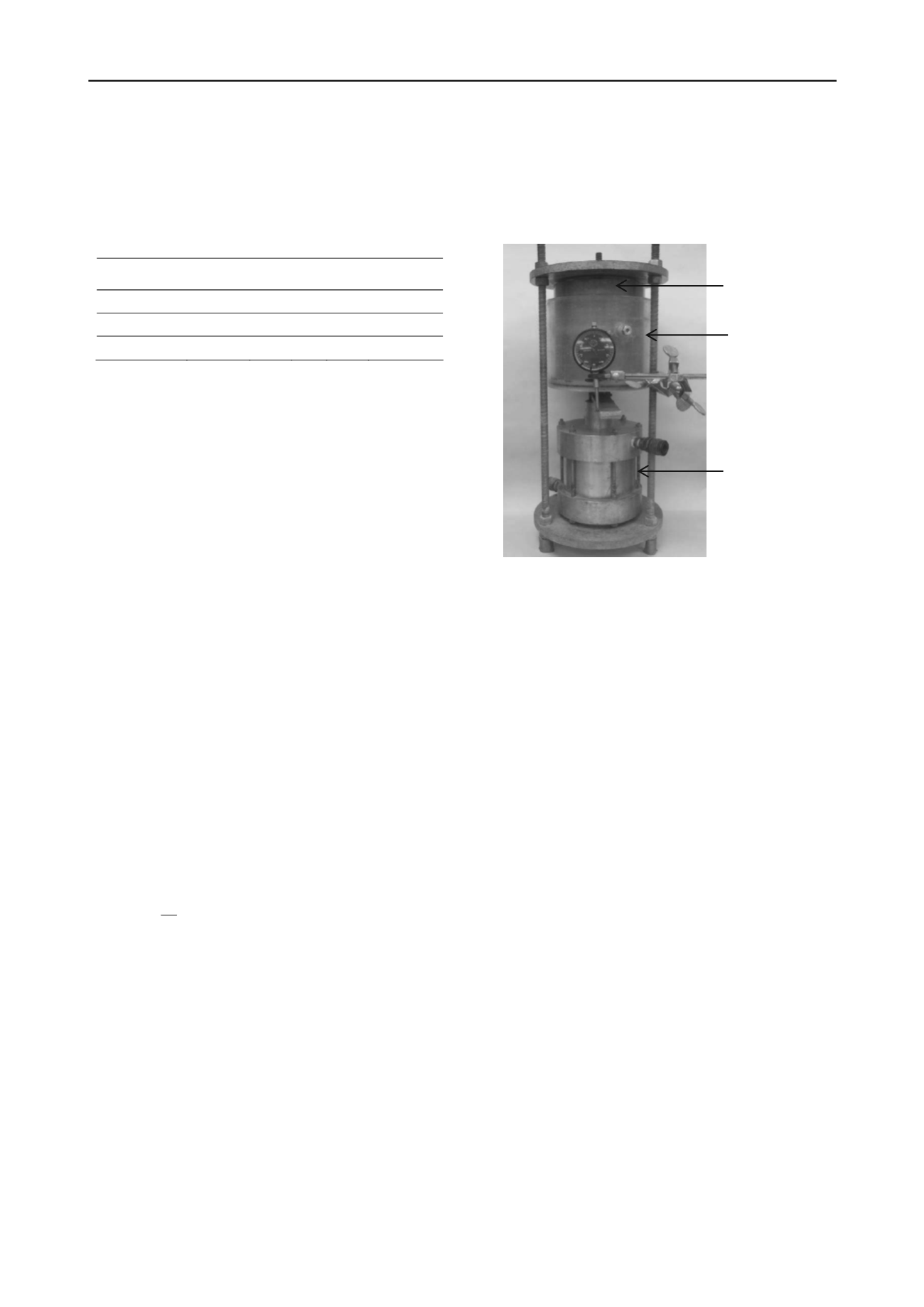

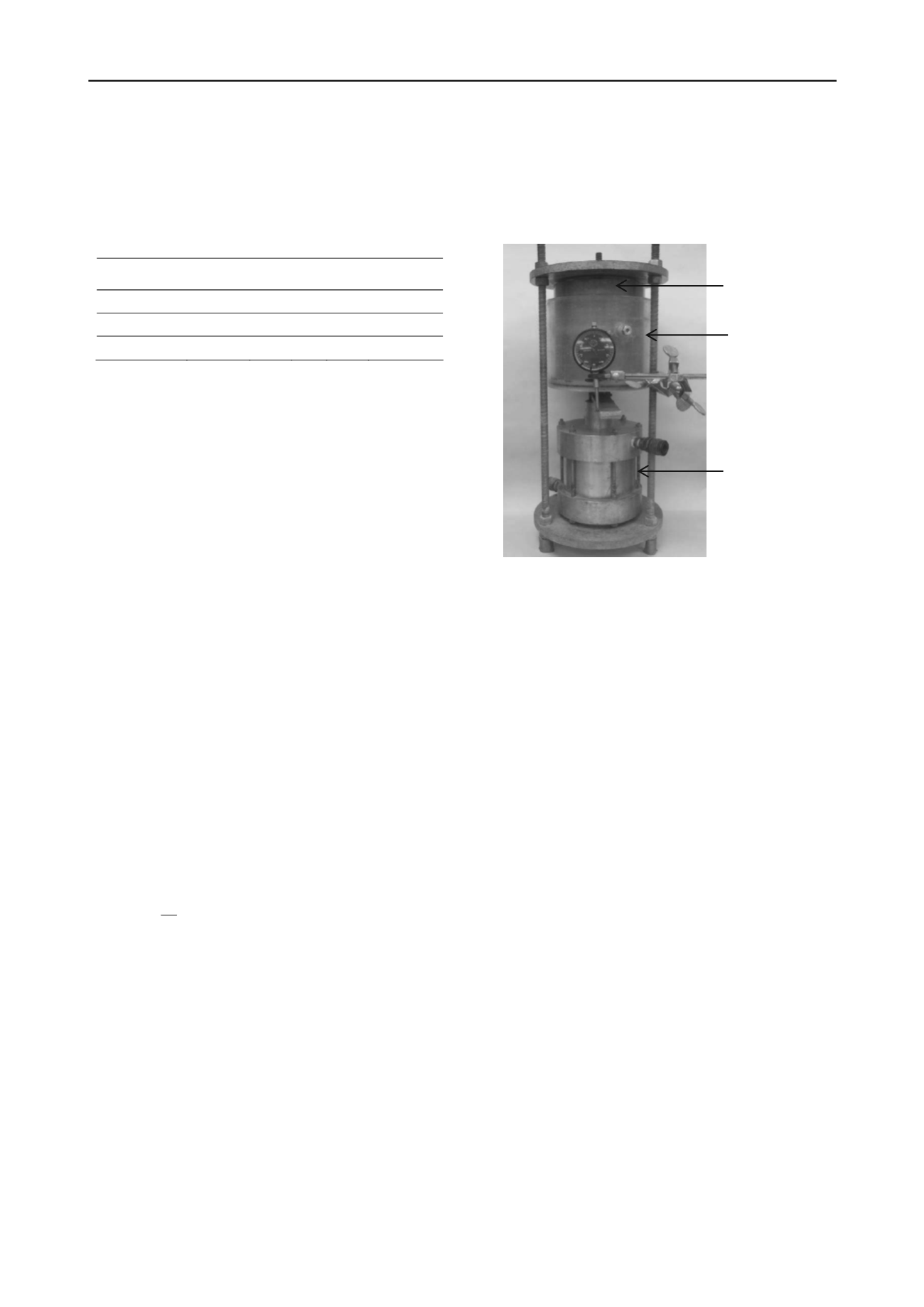

Triaxial test specimens were more difficult to form for tests

at low effective consolidation stresses. At a water content equal

to the liquid limit, the soil does not have the shear strength

required to be formed into triaxial test specimens that can be

installed in a triaxial cell. For this reason, a batch of soil was

first consolidated in a batch consolidometer under K

o

conditions

to a vertical pressure of 38 kPa. The batch consolidometer used

in this investigation is shown in Figure 2. After the batch of soil

reached the end of primary consolidation, the sample was

extruded from the specimen container, and triaxial test

specimens were trimmed. The batch consolidometer formed

samples that had a diameter of 15 cm, which allowed five to six

3.6 cm diameter test specimens to be trimmed. The triaxial test

specimens were then installed in a triaxial cell, back pressure

saturated, and consolidated to an all-around pressure ranging

from 48 kPa to 483 kPa prior to shearing. The samples were

sheared slow enough to allow equilibration of the pore pressures

according to the criterion presented by Head (1986).

The results from the triaxial and direct shear tests performed

on remolded samples are presented in Figure 3. The envelopes

were clearly non-linear, and a power function was fit to the test

results. The power function used was consistent with the format

described by Lade (2010) (see Eq. 1).

b

a

a

'

a p

p

(1)

with:

′

= normal effective stress on the failure plane

p

a

= atmospheric pressure in the same units as

′.

a and b = curve fit parameters.

The results show that no significant differences were

obtained in the failure envelope determined with the direct shear

device and triaxial device for these remolded samples.

4 DISCUSSION

The difference in the results of the triaxial and direct shear tests

on undisturbed and remolded samples can be explained, in part,

by the difference in soil structure. The undisturbed tests

specimens obtained from the greater New Orleans area were

lacustrine and riverine alluvial deposits. These soils were

deposited in horizontal layers, and could be expected to have a

preferential structure. Upon visual inspection, the New Orleans

soils appear to be relatively homogenous. Distinct layering is

often not discernible. Shown on the left side of Figure 5 is a

section cut through an undisturbed New Orleans sample. The

right side of Figure 5 shows the same sample after drying. The

horizontal layers, which can represent planes of weakness,

become evident after drying.

Specimen

Container

Water Bath

Pneumatic

Piston

Figure 2. Batch consolidometer.

This horizontal layering can influence the shear strength

measured using the direct shear device. In the direct shear

device, the failure plane is horizontal. This forced failure plane

can sometimes coincide with the natural layering or planes of

weakness. In the triaxial device, the failure plane is not

predetermined by the configuration of the device and horizontal

planes of weakness would not be expected to control the

measured shear strength. The difference in shear strength as a

function of failure plane orientation has been documented by

many investigators (Duncan and Seed 1966a; b; Filz et al.

1992).

Remolding soil destroys any previous layering or structure

that might have been present, and the resulting sample is more

or less homogenous. The influence of the failure plane

orientation should be much less prevalent as compared to

undisturbed samples. This suggests that fully softened shear

strength (i.e. remolded normally consolidated peak shear

strength) might be less dependent on the choice of the test

apparatus than undisturbed shear strength.

5 CONCLUSIONS

The choice of using direct shear tests or triaxial tests to

determine drained shear strength parameters can be important

for natural soil deposits. Although these two different test

methods can often provide similar results in some soil deposits,

there is considerable evidence that direct shear tests provide

much lower friction angles in riverine and lacustrine alluvial

deposits than triaxial tests. A comparison of numerous CD

direct shear and CU triaxial test results conducted on alluvial

soils from the greater New Orleans area show that the friction

angle determined from the direct shear apparatus is normally

about 2 to 5 degrees lower than that determined using the

triaxial apparatus. This can be attributed to the anisotropic

shear strength characteristics of the alluvial soils.

The difference in the results of the two test devices is much

less when remolded test specimens are used. The remolding

process destroys the anisotropic fabric, and the shear strength

parameters are not as dependent on the orientation of the failure

plane. When fully softened shear strength parameters are

desired, direct shear and triaxial test apparatuses appear to

provide comparable results.