315

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

a function of the confining pressure (

’

3

) and the void ratio (e)

ma be defined by the following expression:

y

E

i

=A

.

'

3

n.

e

-1

(1)

where A, n are constants that depend on the type of soil (Biarez

et al., 1993; Bard,1993).

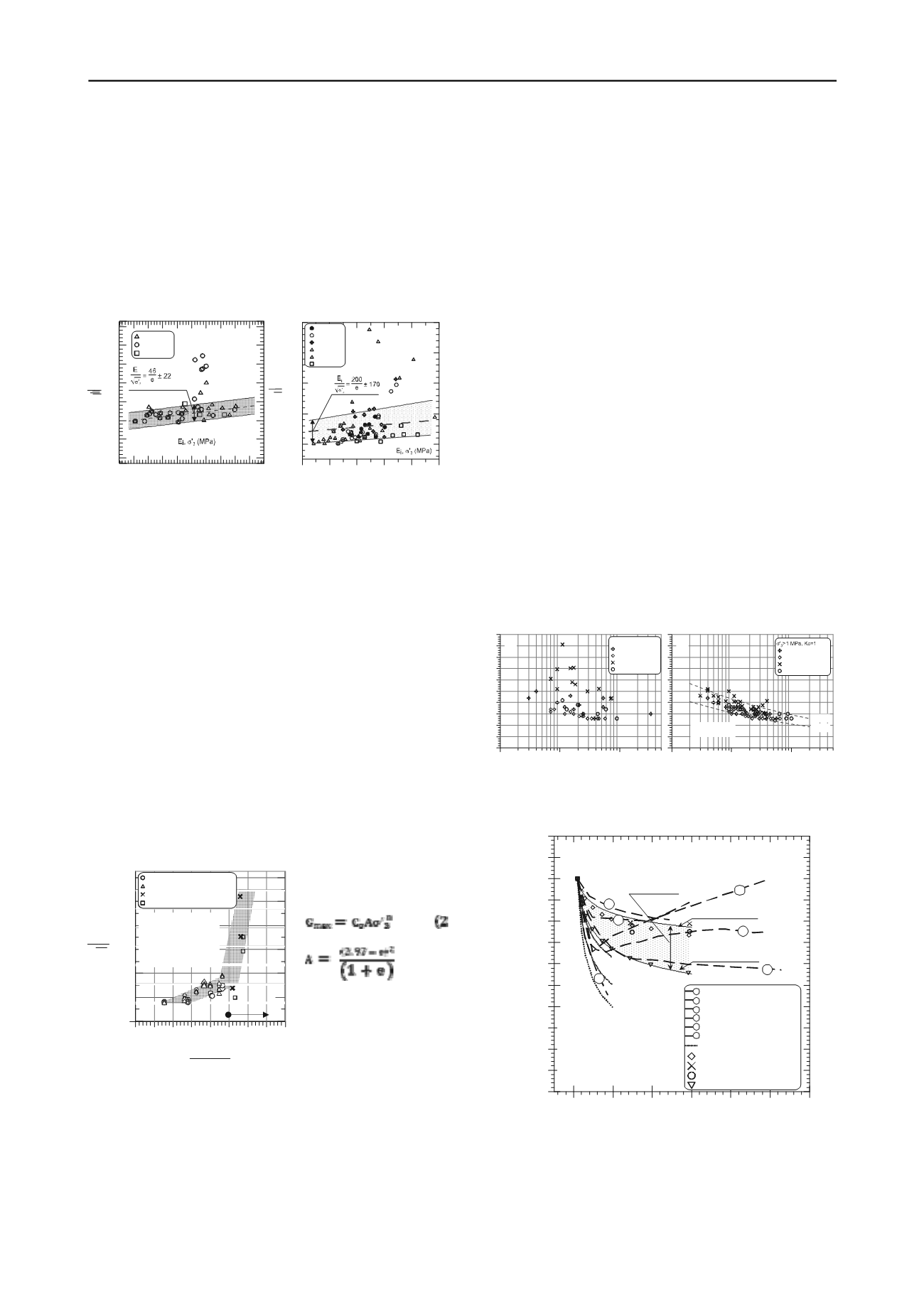

Figures 5a and 5b present the values of E

i

obtained through

the hyperbolic adjustment of the stress-deformation curves, for

the tests performed at different initial densities and different

fines contents in drained and undrained conditions (large

deformations).

1

1.2

1.4

1.6

1.8

2

1/e

-200

0

200

400

600

800

1000

E

i

'

3

18- 21% F

15% F

30% F

E

i

'

3

=

148

e ± 70

E

i

= Módulo Tangente Inicial

E

i

y

' 3 (kg/cm

2

)

-50

50

100

150

200

25

300

i

'

3

a)

1

1.2 1.4 1.6 1.8

2

1/e

0

500

1000

1500

2000

E

i

'

3

12% Fines

15% Fines

18% Fines

21% Fines

20% Fines

30% Fines

b)

Figure 5. Normalized E

i

variation. All the sands tested: a) drained case,

b) undrained (Campaña, 2011).

In case of the drained tests, the resulting values of E

i

are all

practically contained in a narrow band, even when the range of

fines content of the sample vary between 15% to 30%. In the

case of the undrained tests, a significant dispersion was

observed which may be explained by the variation of the pore

pressure according the initial value of

'

3

and density (e). The

lower values of E

i

correspond to 30% fines and the higher

values correspond to fines between 15% and 21%.

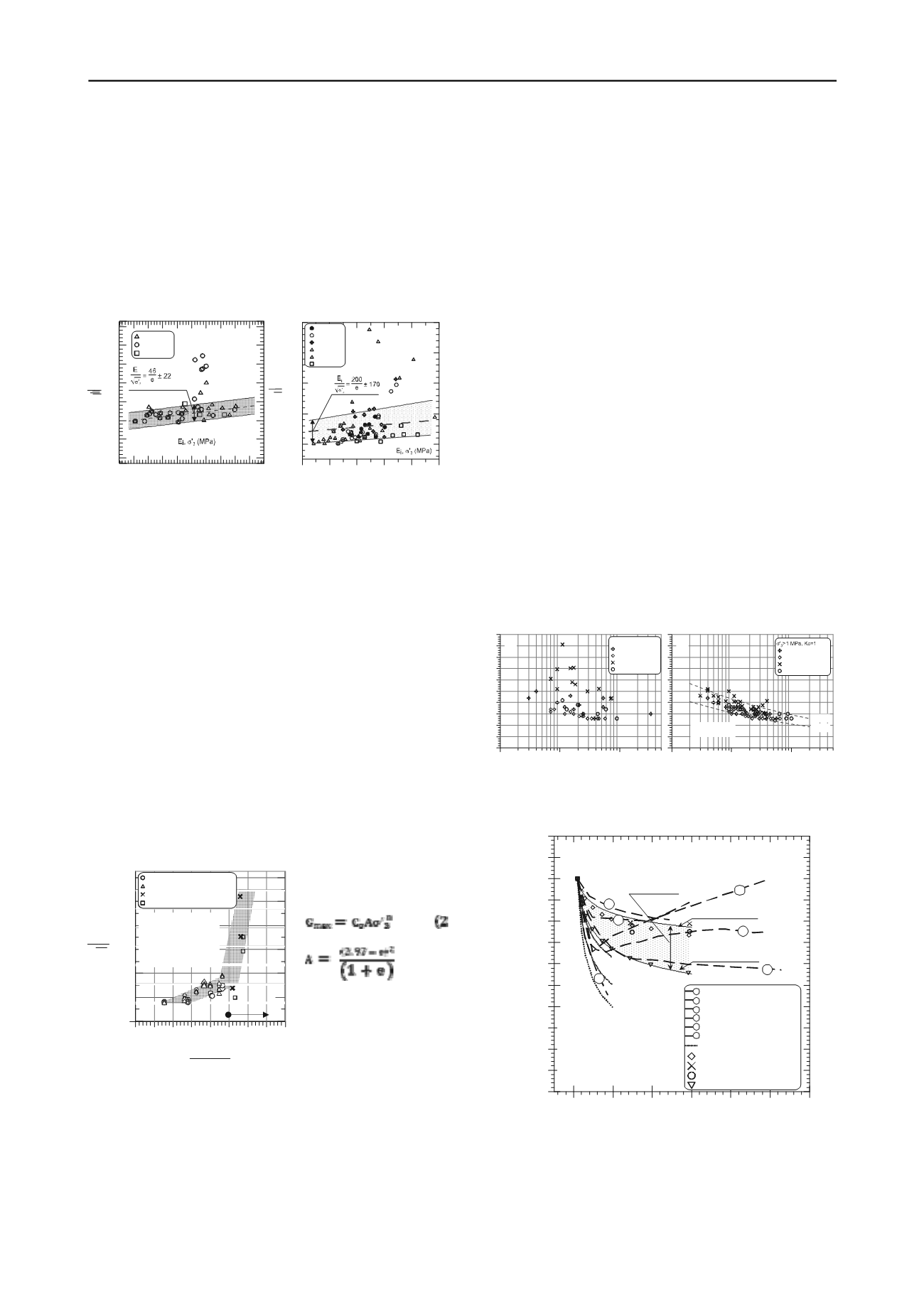

7 SHEAR MODULUS G

MAX

(

<10

-5

)

According to Hardin & Drnevich (1972), the variation of the

shear modulus at small deformations (G

max

) as a function of the

confining pressure

(

’

3

) and the void ratio

(e) may be expressed

as indicated by equation (2), where C

0

and n are constants of the

material. Plotting the results of the tests (triaxial at small

deformations in Sands S1 and S2; resonant column for S3) in

one graph to determine the values of C

0

and n of equation (2), it

was observed that, for the range of pressures and densities

tested, the tendency of expected variation for confining

pressures

'

3

<1 MPa is reproduced, which does not occur for

'

3

>1 MPa (Figure 6).

0

200

400

600

800

1000

1200

G

MAX

��

'

3

2.5

3

3.5

4

4.5

(2,97-e)

2

(1+e)

0

500

1000

1500

2000

2500

3000

3500

4000

'

0

18%F, Triaxial (S3)

18%F,C.Resonante(S3)

15%F, Triaxial (S1)

21%F, Triaxial (S1)

= [10 -6 - 10-5 ]

e=[0.52 - 0.73]

'

0

= [1 - 30 kg/cm

2

]

�

= [10 -

6

- 10-

5

]

e = [0.52 - 0.73]

�

'

3

= [0.1 to 2.94 MPa]

18 Fines, Sand S3 (triaxial test)

18 ines, Sand S3

(ResonantColumn)

15 Fines, Sand S3 (triaxial test)

21 Fines, Sand S3 (triaxial test)

Hardin & Drnevich (1972)

Figure 6. Results of resounding column and triaxial at small

deformations tests (Campaña, 2011).

8 CYCLIC SHEAR RESISTANCE (CSR)

The cyclic triaxial tests were carried out on reconstituted

samples with a nominal diameter of 5 cm (S1, S2 and S4) and

7 cm (S3) and nominal heights of 10 cm and 15 cm,

respectively. In all cases, parameter B at the end of the

applied according to the magnitude of isotropic confining

pressure: 0.3 MPa for Sands S1, S2, and S4 and up to 0.9 MPa

for Sand S3. A uniform sinusoidal cyclic load was applied with

a frequency of 0.1 Hz for Sand S4 and of 0.05 Hz for Sands S1,

S2, and S3. Test results are summarized in several graphs,

differentiated by the fines content, confining pressure, and

density achieved at the end of the consolidation stage (see

Campaña 2011). The results of this tests confirm the tendency

reported by Verdugo (1983) for lower confining pressures

(

’

3

≤ 0.5 MPa), related to the decrease of the required CSR to

produce liquefaction when the non-plastic fines content

increases. However, this tendency disappears for confining

pressures greater than 0.5 MPa where the CSR practically is a

constant. To strengthen this important detection, all the results

obtained have been plotted separately on Figure 7a for

’

3

≤ 0.5 MPa, and on Figure 7b, for

’

3

≥ 1 MPa. On Figure 6a,

a great scattering in the CSR values can be observed for the four

sands tested, while a general decreasing trend of CSR values

with the increasing number of cycles can be perceived. The

results corresponding to Sand S3 contribute significantly to the

width of the resulting band. Contrary, on Figure 6b for

’

3

≥1 MPa, the CSR values obtained range in a very narrow

band, without important differences due to initial density or

fines content or the cycloned tailings sands.

Another relevant aspect to point out from

saturation stage was greater than 0.95. Backpressure was

the results of the

tests carried out in Sands S2 and S4 for confining pressures

greater than 0.5 MPa, are the relatively constant CSR values

obtained despite the confining pressure applied (factor K

=1),

the fines content, the relative density, and even the initial shear

stress. Figure 8 presents a comparison of K

values obtained in

this paper with those obtained by several authors.

1

10

100

Número de Ciclos,N (

u=

'

0

)

0

0.1

0.2

0.3

0.4

0.5

Rc (

cy/

o')

'

3

10 (kg/cm

2

), Kc=1

ArenaS1

ArenaS2

ArenaS3

ArenaS4

Rc=A*N -

0.17

A=0.32

A=0.23

b)

Number of Cycles, N (

u=

'

3

)

Sa d

Sa d

Sa d

Sa d

0.5

1

10

100

Número de Ciclos, N (

u=

'

0

)

0

0.1

0.2

0.3

0.4

'

3

5 (kg/cm

2

),Kc=1

ArenaS1

Rc (

cy/

o')

ArenaS2

ArenaS3

' <0.5MPa,Kc=1

a)

CSR

=

cy

/

'

3

ArenaS4

Number of Cycles, N (

u=

'

3

)

CSR=A

.

N

-

0. 7

F 7. Summary all test results: a) for

’

3

≤ 0.5 MPa, b) for

igure

’

3

≥ 1MPa, Kc= 1.0 (Campaña, 2011)

0

1

2 3

4 5

'

3

(MPa)

6

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

K

Maureira (2012)

Santos (2011), 55% F

Solans (2010), 15% F, D

R

*=60

Riemer et al (2008), 15% F, 98% SP*

Seed & Harder (1990)

Vaid (1985)

Youd et. al (2001)

**

Sand S1 - 15% F - D

R

=49%

Sand S1 - 15% F - D

R

=56%

Sand S1 - 21% F - D

R

=56%

Sand S3 - 12 & 18% F - 56<D

R

<86%

This study range

K

=0.84(

'

3

)

-0.08

,[DR~50%]

1

K

=0.67(

'

3

)

-0.17

,[DR~70%]

4

5

6

3

2

D R <40%

DR~60%

DR>80%

1

2

3

5

6

4

D R : Relative Density after consolidation

D R *: before consolidation

SP: Standar Proctor

F : Fines content

** : Recommendation for natural sands

1996 & 1998 NCEER workshop

Tailing Sand Samples, except:

- Santos (2011), Tailing

- Seed & Harder (1990), Several natural sand

Figure 8. Variation of factor K

with regard to

’

3

9 CONCLUSIONS

The interpretation and analysis of the results of the testing

program show that, in the domain of confining pressures applied

DR>75%