318

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

shear device, the magnitudes of the intermediate and minor

principal stresses are not known and are governed by the

vertical stress applied and the strength properties of the soil

being tested.

Progressive failure is the condition where the peak shear

strength is not mobilized in every point of the failure plane at

the same instance. This is caused by the non-uniform

distribution of strain in the failure plane combined with the

strain-softening characteristic of the soil. Some locations on the

failure plane will mobilize the peak shear strength while others,

having achieved more or less displacement, will mobilized a

shear strength below the peak shear strength. For the direct

shear device, investigators have reached different conclusions

about the effect of stress concentrations in this device. Hvorslev

(1960) measured horizontal displacements along the failure

plane in a direct shear device and found that the displacements

are not uniformly distributed, thereby causing progressive

failure to occur. Alternatively, a finite element study of the

direct shear box presented by Potts et al. (1987) showed that

although stress concentration exist on the failure plane of the

direct shear box, at the moment of failure the stresses on the

failure plane are more or less uniform and the peak shear

strength measured is not affected by progressive failure. For the

triaxial device, stress concentration caused by the end restraints

can influence the results. Research performed by Taylor (1941)

showed that if the ratio of length to diameter is between 1.5 and

2.5, the effect of the stress concentration is negligible.

In the direct shear device, the orientation of the principal

stresses on the failure plane varies during the shearing stage of

the test and the final orientation is unknown. In the triaxial test,

the major and minor principal stresses act on the horizontal and

vertical planes and this orientation does not change during

shear.

The orientation of the failure plane in the direct shear device

is predetermined as being near the midpoint between the upper

and lower halves of the shear box. In the triaxial device, the

orientation of the failure plane is governed by the soil structure

and the strength properties of the soil.

A literature review was undertaken to locate previous

comparisons of the shear strength obtained using the triaxial and

direct shear apparatuses. Skempton (1964) stated that the same

effective stress shear strength parameters were obtained from

tests conducted on eight specimens of Boulder Clay using the

direct shear and triaxial devices. Casagrande and Poulos (1964)

presented the results of CD direct shear and CD triaxial tests

performed on compacted specimens of a lean clay which

showed that about the same shear strength envelope was

obtained with the two tests. Moon (1984) performed CD direct

shear and CU triaxial tests on undisturbed samples of a fat clay

and found differences of less than one degree for the effective

stress friction angle and less than 8 kPa for the effective

cohesion intercept obtained from these two tests using the

maximum principal stress ratio as the failure criterion. Thomson

and Kjartanson (1985) performed CD direct shear tests and CD

and CU triaxial tests on undisturbed samples of a lean clay and

a fat clay and found that the results plotted on the same failure

envelope. Abdel-Ghaffar (1990) compiled results from the

literature where direct shear and triaxial tests were performed

on undisturbed samples of the same soil. He concluded that the

direct shear and triaxial devices provide comparable values for

the effective stress friction angle and cohesion intercept.

Maccarini (1993) performed CD direct shear and CD triaxial

tests on a residual soil from Rio de Janeiro. For these tests, the

tests specimens were oriented so that the failure plane in both

devices coincided with the direction of stratification of the soil.

The stratification of the soil had a dip angle of 25

°

. Based on the

results obtained, Maccarini concluded that similar values of

effective stress cohesion and friction angle are obtained from

both tests if the stratification is taken into account.

Based on the results presented above, it can be seen that the

available information in the literature is divided on whether

these two devices will provide the same effective stress shear

strength parameters. Investigators that have found agreement in

the results did not state whether the soil tested had a preferred

particle orientation or layering that could influence the results.

3 DATA COLLECTION AND RESULTS

3.1

Undisturbed test specimens

A subset of 63 CU triaxial test series and 146 CD direct shear

test series was selected from the test results available from the

New Orleans investigation. Each test series normally consisted

of three individual tests conducted at different confining

pressures. Only high quality tests were selected. The test results

selected had to comply with the following requirements: 1) At

least two test specimens were consolidated to stresses that were

higher than the preconsolidation stress; 2) The end of primary

consolidation was achieved during the consolidation stage of the

test, 3) Index properties were available; 4) A peak deviator

stress was reached for CU triaxial tests in less than 15% strain

and a peak shear stress was reached for CD direct shear tests at

a horizontal displacement less than 0.4 inches.

Since all the samples used were normally consolidated, the

shear strength interpretation assumed that the effective stress

cohesion intercept was zero. The least-squares method was used

to obtain the corresponding effective stress friction angle.

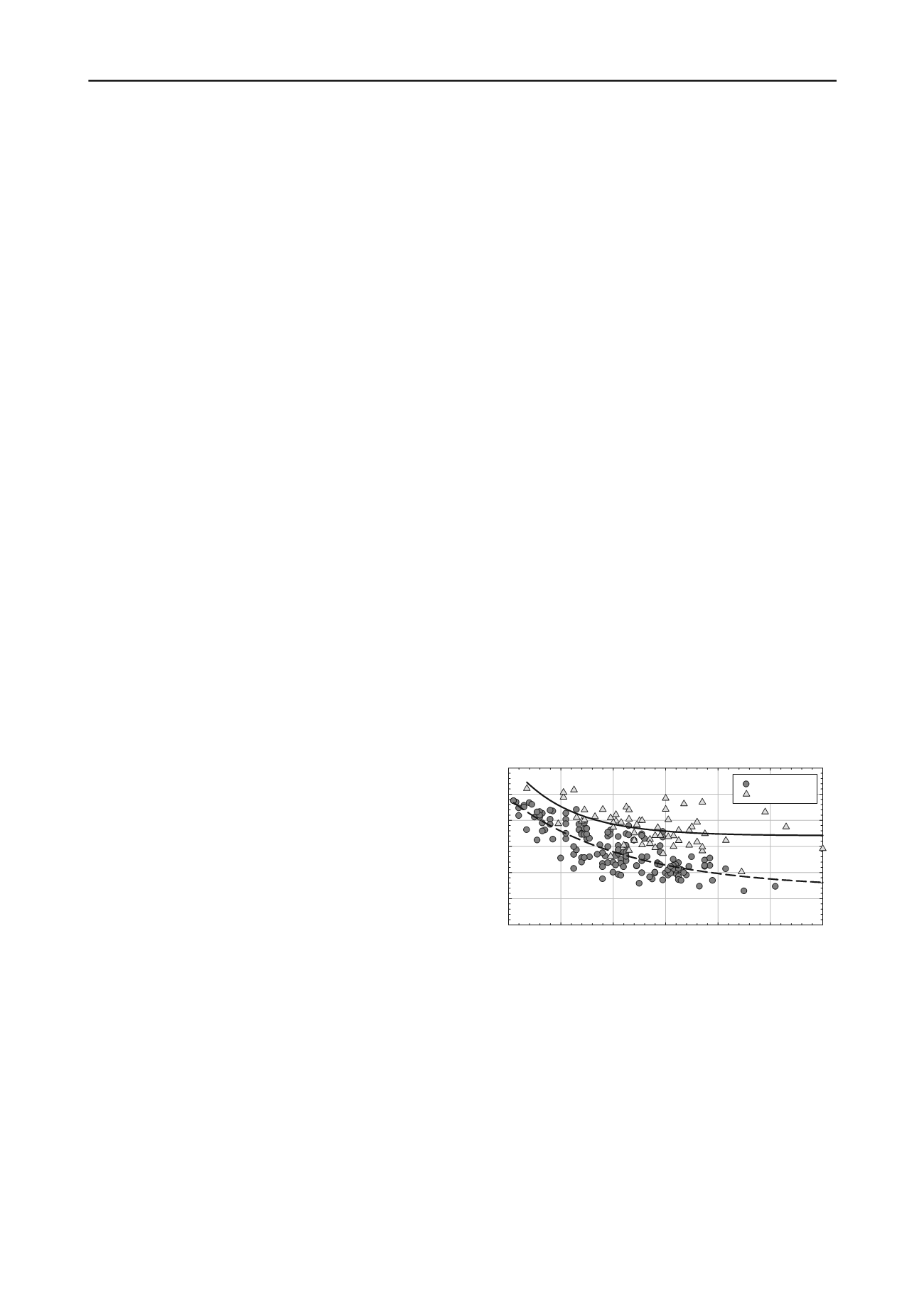

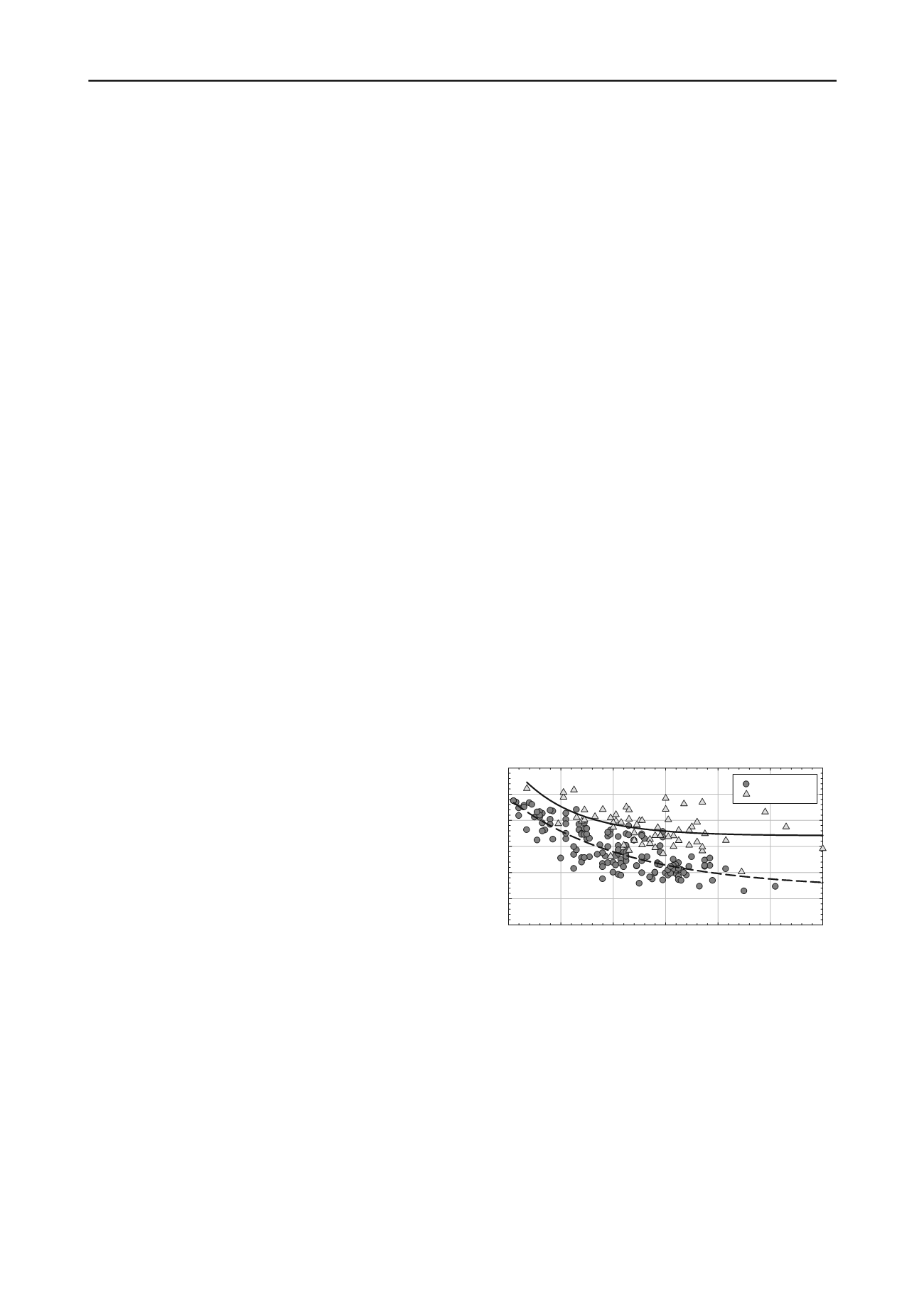

Shown in Figure 1 are the values of the effective stress

friction angles as a function of the Plasticity Index (PI) for the

undisturbed New Orleans area test specimens for CD direct

shear and CU triaxial tests. The trend lines shown on this figure

are based on a statistical analysis performed by the authors.

These lines are presented to better show the trend of the data

and are not intended to be used as a correlation to predict

friction angles. From this figure, it can be seen that the effective

stress friction angle measured with the CU triaxial device is

generally higher than that measured with the direct shear device.

This difference was found to increase with increasing plasticity

index of the soil. In general, the difference in friction angle

ranged from about 2 degrees to 5 degrees.

Plasticity Index (%)

0

20

40

60

80

100

120

Effective Stress Friction Angle (deg)

10

15

20

25

30

35

40

CD Direct Shear

CU Triaxial

Figure 1. Relationship between effective stress friction angle and

plasticity index for CD direct shear tests and CU triaxial tests on

undisturbed samples.

3.2

Remolded test specimens

Three remolded clays were tested to allow a comparison of the

fully softened shear strength measured in CD direct shear tests

and CU triaxial tests. The index properties of these clays are

shown are in Table 1. NOVA clay was obtained from a site in

Northern Virginia in Fairfax County. Vicksburg Buckshot Clay

(VBC) was obtained from the stockpile maintained at the

Engineering Research and Development Center of the U.S.

Army Corps of Engineers. It has been the subject of many

research projects (Ladd and Preston 1965; Mitchell et al. 1965;

Al-Hussaini and Townsend 1974). Colorado Clay is a lean clay

(CL) from Silverthorne, Colorado.

To prepare the remolded samples, the soils were first soaked

in water for at least 48 hours, and then processed through a No.