322

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

bender/extender elements tests were carried out considering

four porosities and five cement contents at four distinct curing

time periods (1, 3, 5 and 7 days).

2.1. Materials

The Osorio sand used in the testing was obtained from the

region of Porto Alegre, in Southern Brazil, being classified as

non-plastic uniform fine sand. Specific gravity of the solids is

2.63. Mineralogical analysis showed that sand particles are

predominantly quartz. The grain size is purely fine sand with a

mean diameter of 0.16 mm, being the uniformity and curvature

coefficients of 1.9 and 1.2, respectively. The minimum and

maximum void ratios are 0.6 and 0.9, respectively.

Portland cement of high early strength (Type III) was used

as the cementing agent. Its fast gain of strength and stiffness

allowed the adoption of 1, 3, 5 and 7 days as the curing time

periods. The specific gravity of the cement grains is 3.15.

Distilled water was used for these characterization tests and

tap water for molding specimens for the compression tests.

2.2. Methods

Molding and curing of specimens, as well as bender element

tests are detailed below.

2.2.1.

Molding and curing of specimens

For the for the bender element tests, cylindrical specimens

70mm in diameter and 140mm high were used. A target dry unit

weight for a given specimen was then established through the

dry mass of soil-cement divided by the total volume of the

specimen. In order to keep the dry unit weight of the specimens

constant with increasing cement content, a small portion of the

soil was replaced by cement. As the specific gravity of the

cement grains (3.15) is greater than the specific gravity of the

soil grains (2.63), for the calculation of porosity, a composite

specific gravity based on the soil and cement percentages in the

specimens was used.

After the soil, cement and water were weighed, the soil and

cement were mixed until the mixture acquired a uniform

consistency. The water was then added continuing the mixture

process until a homogeneous paste was created. The amount of

cement for each mixture was calculated based on the mass of

dry soil and the moisture content. The specimen was then

statically compacted in three layers inside a cylindrical split

mold, which was lubricated, so that each layer reached the

specified dry unit weight. The top of each layer was slightly

scarified. After the molding process, the specimen was

immediately extracted from the split mold and its weight,

diameter and height measured with accuracies of about 0.01g

and 0.1mm, respectively. The samples were then placed inside

plastic bags to avoid significant variations of moisture content.

They were cured in a humid room at 23º±2ºC and relative

humidity above 95%. The samples were considered suitable for

testing if they met the following tolerances: Dry unit weight

(

d

): degree of compaction between 99% and 101% (the degree

of compaction being defined as the value obtained in the

molding process divided by the target value of

d

); Dimensions:

diameter to within ±0.5mm and height ±1mm.

The molding points were chosen considering relative

densities of 10%, 33%, 66% and 90%, with the same moisture

content (about 10%). Each point was molded with five different

cement percentages: 1%, 2%, 3%, 5% and 7%. These

percentages were chosen considering the Brazilian and

international experience with soil-cement [e.g., Mitchell (1981),

Consoli

et al.

(2010, 2012b)], both in experimental and practical

work.

2.2.2.

Bender/extender element tests

T-shaped pairs of bender/extender (BE) elements, installed on

the top and bottom specimen platens, were used in present study

for emission and reception of shear “S” waves (2 to 20 kHz

frequencies) and compression “P” waves (20 to 80 kHz

frequencies), being directly related to shear and oedometric

moduli measurement, respectively. The bender/extender

elements penetrated the specimen by 3mm at each end. For

present sand-cement mixtures, time domain method of

identification of first arrivals was adopted.

Single sine-wave input pulses were used at pre-set

frequencies of 1, 3, 5, 7, 9, 11, 13 kHz, which covered the range

of resonant frequencies of the sample-BE system. The output

signals were captured on an oscilloscope, directly transferred to

the PC and plotted to a common time base. The first arrival of

the shear wave was taken (on the basis of previous calibration)

as the point at which the wave descended, with low noise higher

frequency results being preferred in order to avoid near field

effects.

3 RESULTS OF STIFFNESS MEASUREMENTS

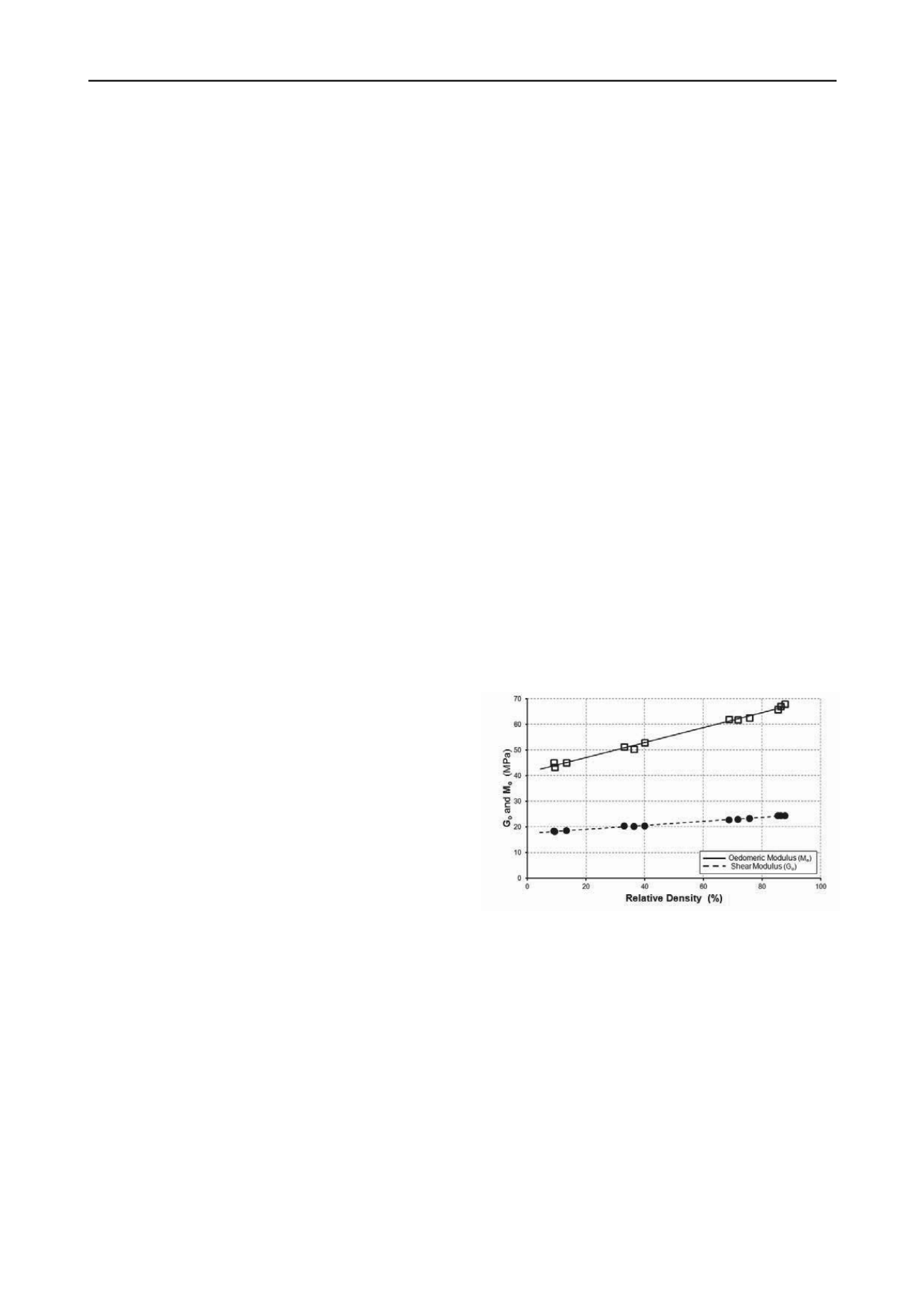

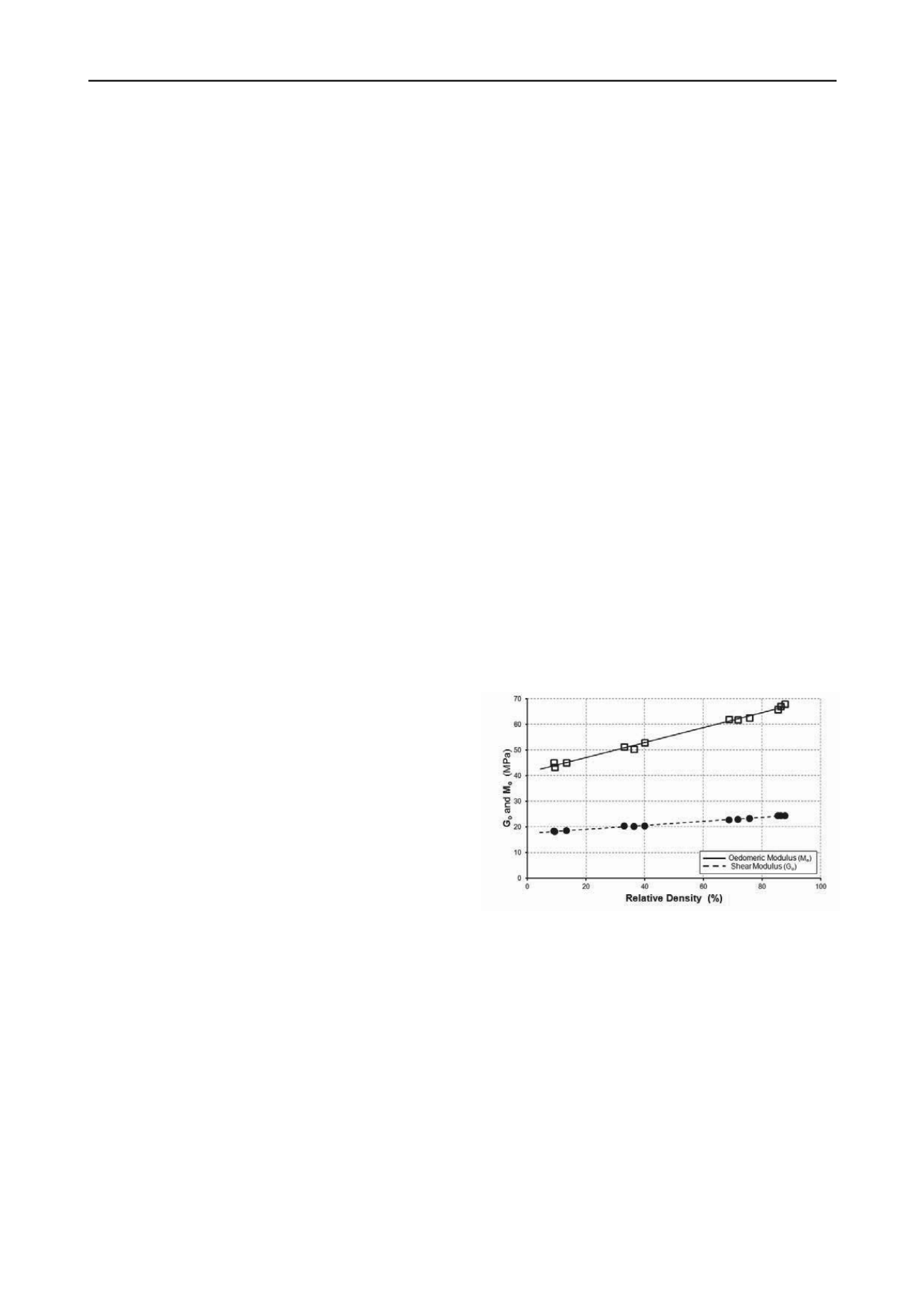

Results of both initial shear (G

o

) and initial oedometric (M

o

)

moduli versus relative density (DR) of Osorio sand are

presented in Figure 1. Equations (1) and (2), fitted from

experimental data, give the expressions of G

o

and M

o

with

relative density of Osorio sand.

DR

MPa

G

sand

o

076 .0 60.17 )

(

(1)

DR

MPa

M

sand

o

294 .0 18.41 )

(

(2)

Figure 1. Shear (G

o

) and oedometric (M

o

) moduli versus relative density

for Osorio sand.

Results of G

o

and M

o

on artificially cemented are also

presented in Figures 2, 3, 4 and 5, respectively for, 1, 3, 5 and 7

curing days.

Figure 2 presents the variation of the shear (G

o

) and

oedometric (M

o

) modulus with porosity/cement ratio (

/C

iv

)

considering all four studied relative densities (10, 33, 66 and

90%), five cement contents (1%, 2%, 3%, 5% and 7%) and 1

(one) day of curing. Equations (3) and (4) present the variation

of G

o

and M

o

with

/C

iv

, both with high coefficient of

determination (R

2

=0.95 and 0.93, respectively for shear and

oedometric modulus).