332

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4

Factors G and S may be different between the full-scale backfill

and the one used in laboratory stress-strain tests.

To evaluate factors S and G, a series of drained TC tests were

performed using small and large CMG specimens of the same

gravelly soil but having four different grading curves, PG, SAG,

CG and OBG shown in Fig. 1, produced from an original

gravelly soil (OBG), a sub-angular crushed sandstone as Chiba

gravel but from another quarry. Among these sieved materials,

SAG was produced just by removing particles larger than 10 mm.

The fact that SAG is easiest to produce is a strong advantage for

the use in tests performed in practice. On the hand, PG is

extremely time-consuming to produce, as a large amount of fine

particles should be produced. So, the use of this material in

practice cannot be recommended. The production of CG is

intermediate. The compaction curves of these sieved materials

are noticeably different due to different grading curves (Fig. 2b).

The small specimens have the same size as those of which the

data are presented in the preceding sections. The large specimens

are 300 mm in diameter and 580 mm in height. All the specimens

were prepared under the same conditions: i.e.,

c/g

= 4.0 % and

D

c

= 95 % at the respective optimum water contents by 4.5E

c

. As

the

ρ

d_max

values of these sieved materials are nearly the same

(Fig. 2b), the eventually obtained compacted dry densities are

very similar.

0 20 40 60 80 100 120 140

0.0

4.0

8.0

12.0

16.0

ML TC tests (specimen from Kikonai site)

D

c

=100% (4.5Ec); c/g=3.0%;

h

'=20kPa

Bottom of bridge abutment (boring)

Top of bridge abutment (core-cut)

Fitting based on Eq. (3)

Using the parameters deduced by:

Method 1): q

0

= 1.61

a= 6.7; or

Method 2): a= 7.7

q

0

= 1.43 MPa

Maximum deviator stress q

max

(MPa)

Time (day)

28 days

Figure 7. Compressive strength

q

max

versus total curing time for rotary

core samples from the field (Kikonai GRS integral bridge) and fitting

curve based on Eq. (3) with a set of deduced parameters (Fig. 6a and b)

0.0

0.5

1.0

1.5

0.0

2.0

4.0

6.0

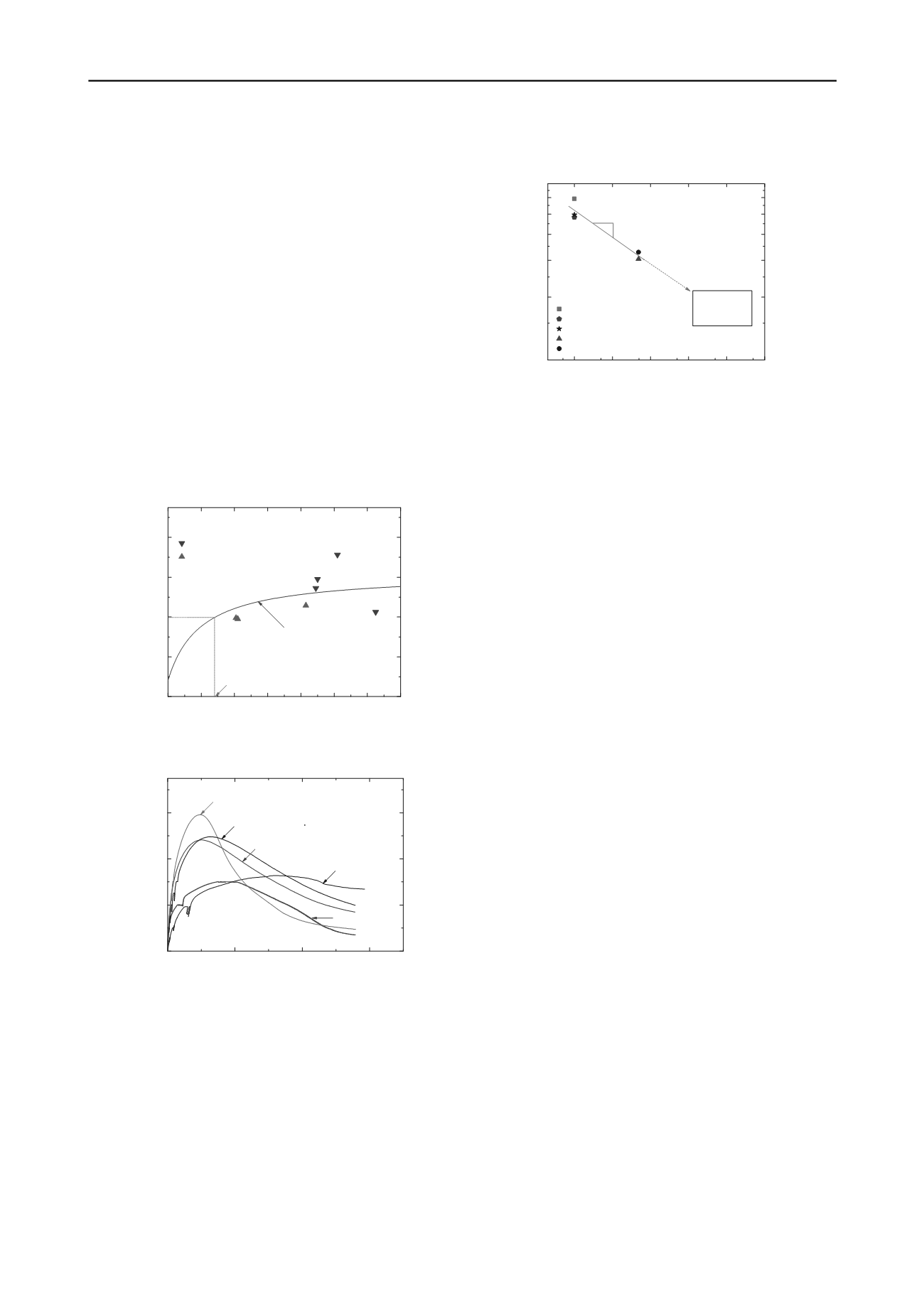

Small TC (SAG)

Small TC (PG)

Large TC (OBG)

Deviator stress, q (MPa)

Vertical strain,

v

(%)

ML TC test -

h

'=20kPa

Cured for 7 days

D

c

=95%(4.5Ec) c/g=4.0%

v

=0.03%/min

Large TC (SAG)

Small TC (CG)

Figure 8. Deviator stress (

q

)

–

vertical strain (

v

) relations from CD TC

tests at

h

’=20

kPa on small and large specimens having different types

of cement-mixed gravel presented in Fig. 1

Fig. 8 shows the stress-strain curves at

t

c

= 7 days of the small

and large specimens of SAG, CG and OBG. The effects of

specimen size (factor S) are significant, while the effects of

grading characteristics (factor G) are not so. It was found that

there is no trend in the relationship between

q

max

and

D/d

50

(also

with

D/d

ma

x

). On the other hand, a well-defined trend exists in the

relationship between

q

max

and the ratio of the specimen volume

to the small specimen volume

V/V

small TC

(Fig. 9): i.e.,

q

max

decreases nearly 40 % with an increase in the specimen volume

by a factor of nearly 50. This fact indicates that Eq. (3) should be

modified to take into account this size effect. More research is

necessary to examine whether this linear relation can be extended

to volumes that exceeds the largest value examined in this study

(such as field full-scale structures).

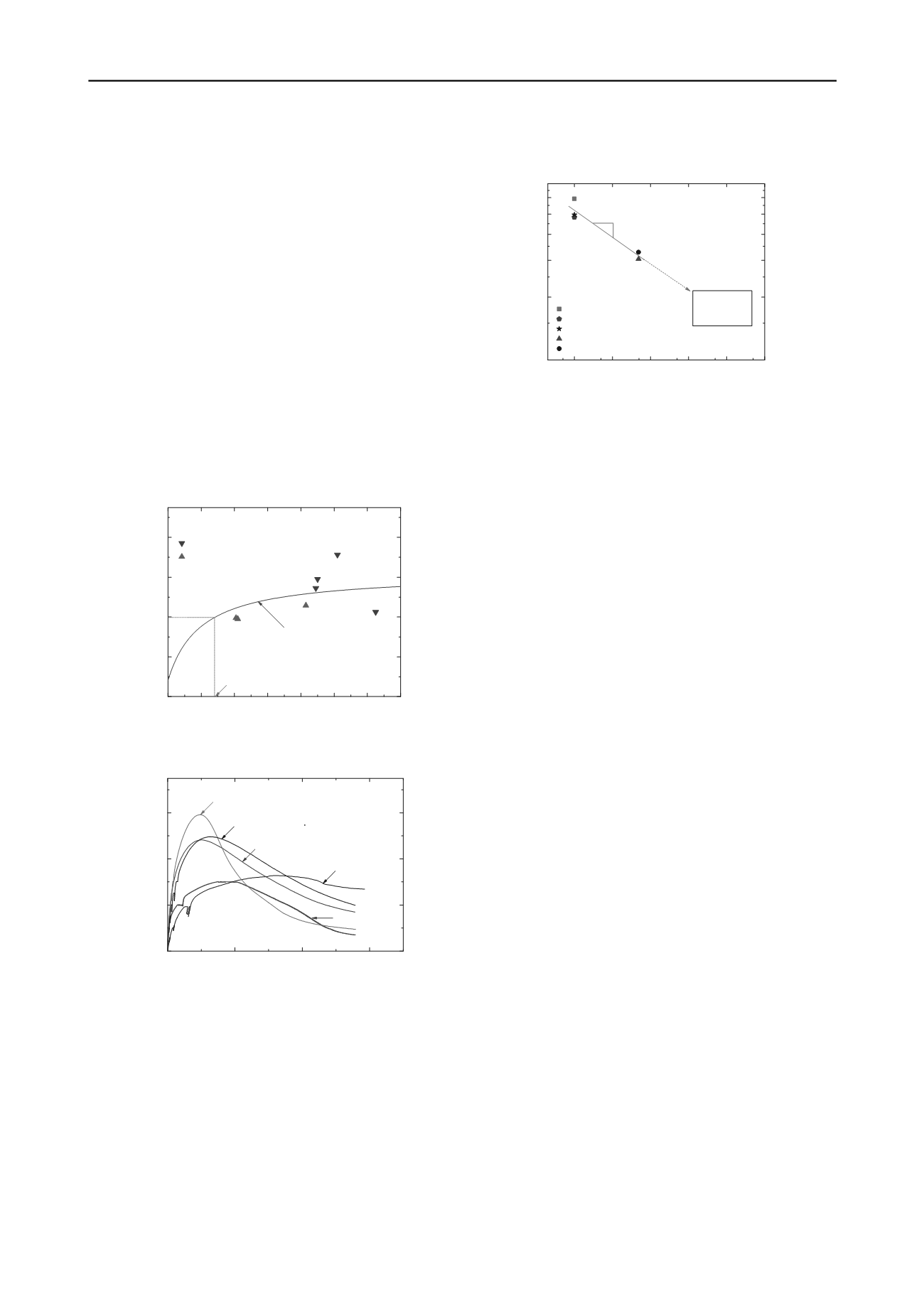

10

0

10

1

10

2

10

3

10

4

10

5

1.0

2.0

3.0

4.0

5.0

6.0

7.0

1/8

Small TC (PG)

Small TC (CG)

Small TC (SAG)

Large TC (OBG)

Large TC (SAG)

Maximum deviator stress, q

max

(MPa)

Volume ratio,

V/V

SmallTC

Field full-scale

structure

1

Figure 9. Compressive strength

q

max

(

D

c

= 95 % at 4.5Ec);

c/g

= 4.0%; &

t

c

=7 days) plotted against normalized volume by the volume of the small

specimen

V

Small TC

4 CONCLUSIONS

The following conclusions can be derived:

1. High compaction is very effective to obtain high strength of

cement-mixed gravelly soil (CMG).

2. The porosity of the skeleton of gravelly soil only,

n

s

; and the

fraction of the void of soil skeleton occupied by cement,

C

r

, are

two major independent parameters for the strength of CMG. An

empirical equation is proposed to predict the compressive

strength of a given CMG based on a given initial compressive

strength that is a function of

n

s

with an increase with curing time

following a function of

C

r

.

3. Within the limit of test conditions in the present study, for the

same degree of compaction at the respective optimum water

contents with the same cement content, the effects of grading

characteristics on the strength are not significant, while the

effects of specimen volume are significant.

5 ACKNOWLEDGEMENTS

The core samples from Kikonai were provided by the Japan

Railway Construction, Transport and Technology Agency and

the study was financially supported by Japan Society for the

Promotion of Science.

6 REFERENCES

Consoli,

N.C., Foppa, D., Festugato, L. and Heineck, K.S. (2007): “

Key

parameters

for strength control of artificially cemented soils”,

J.

Geotech. Geoenviron. Eng.

, 133(2): 197

–

205.

Ezaoui,. Tatsuoka, F., Sano, Y., Iguchi, Y., Maeda, Y., Sasaki, Y. and

Duttine, A. (2010): Ageing effects on the yielding characteristics of

cement-mixed granular materials, Soils and Foundations, 50(5), 705-

724.

Horpibulsuk, S., Katkan, W., Sirilerdattana, W. and Rachan, R. (2006):

“Strength Development in Cement stabilized low plasticity and Coarse

grained soils: Laboratory and Field Study”,

Soils and Foundation

,

46(3), 351

–

366.

Kongsukprasert, L. and Tatsuoka, F.

(2005): “

Ageing and viscous effects

on the deformation and strength characteristics of cement-mixed

gravely soil in triaxial compression

”

,

Soils and Foundations,

45(6), 55-

74.

Taheri, A., Y. Sasaki, Y., Tatsuoka, F. and Watanabe, K. (2012):

“Strength a

nd deformation characteristics of cemented-mixed gravelly

soil in multiple-

step triaxial compression”,

Soils and Foundations

,

52(1).

Tatsuoka, F., Di Benedetto, H., Kongkitkul, W., Kongsukprasert, L.,

Nishi, T. and Sano, Y. (2008) Modeling of ageing effects on the elasto-

viscoplastic behavior of geomaterial,

Soils and Foundations

, 48(2),

155-174.

Tatsuoka, F., Munoz, H., Kuroda, T., Nishikiori, H., Soma, R., Kiyota,

T., Tateyama, M. and Watanabe, K. (2012): Stability of existing

bridges improved by structural integration and nailing,

Soils and

Foundations

, 52(2).