330

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2

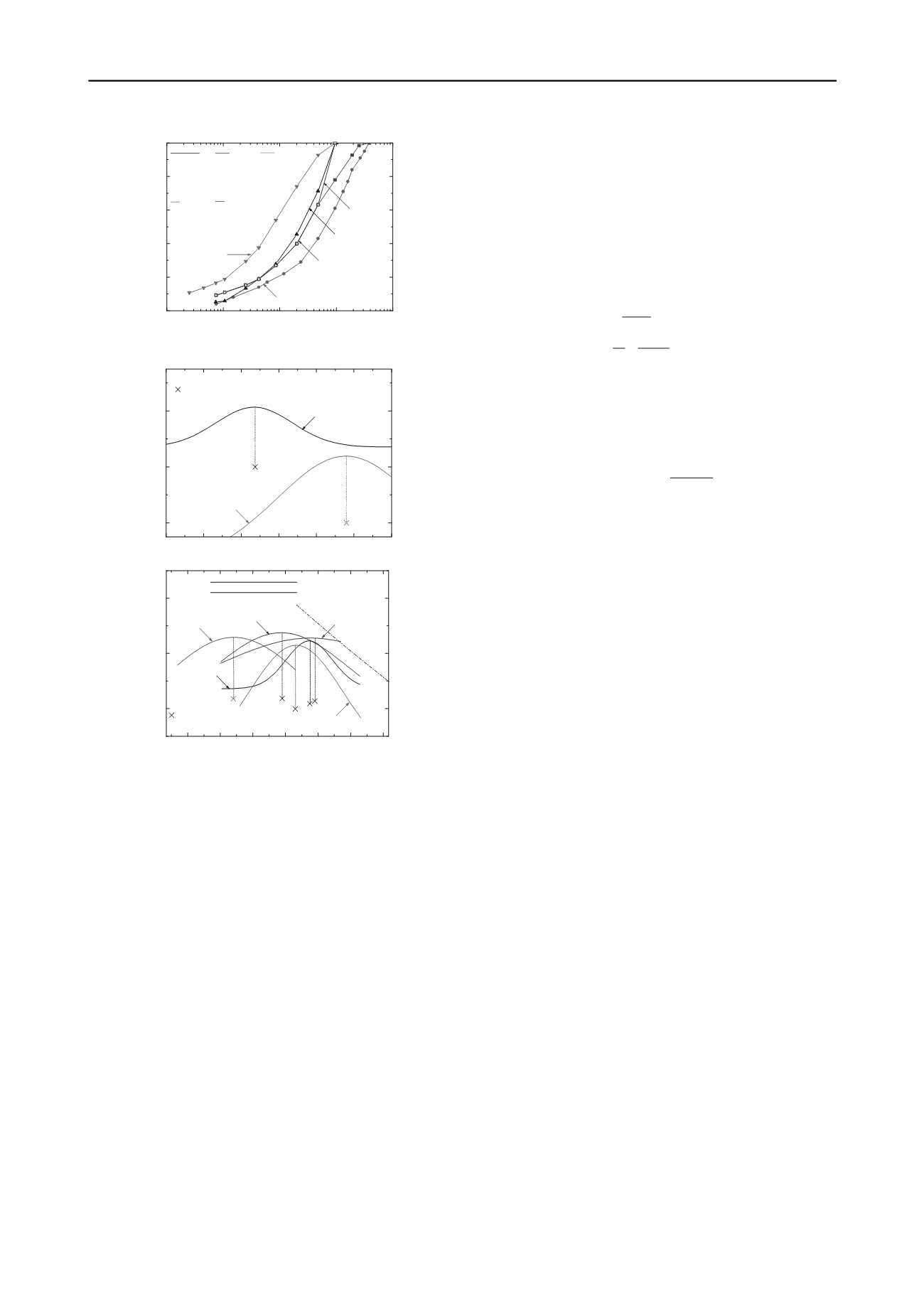

0,01

0,1

1

10

100

0

20

40

60

80

100

Cut grading

(CG)

CG

D

max

= 10 mm

D

50

= 2.92 mm

U

c

= 19.0

F

c

= 9.23 %

Parallel grading

(PG)

PG

D

max

= 10 mm

D

50

= 0.72 mm

U

c

= 50.0

F

c

= 16.5 %

OKG

D

max

= 37.5 mm

D

50

= 6.21 mm

U

c

= 44

F

c

= 4 %

SCG/SAG

D

max

= 10 mm

D

50

= 2.32 mm

U

c

= 19.0

F

c

= 5.2 %

OBG

D

max

= 38.1 mm

D

50

= 2.92 mm

U

c

= 50.0

F

c

= 9.23 %

Sieved grading

(SCG/SAG)

Original crushed

sandstone JR (OBG)

Percent finer than D by weight

Particle size, D (mm)

Original crushed

sandstone Kikonai (OKG)

Figure 1. Grading curves and characteristics of the tested cement-mixed

gravels

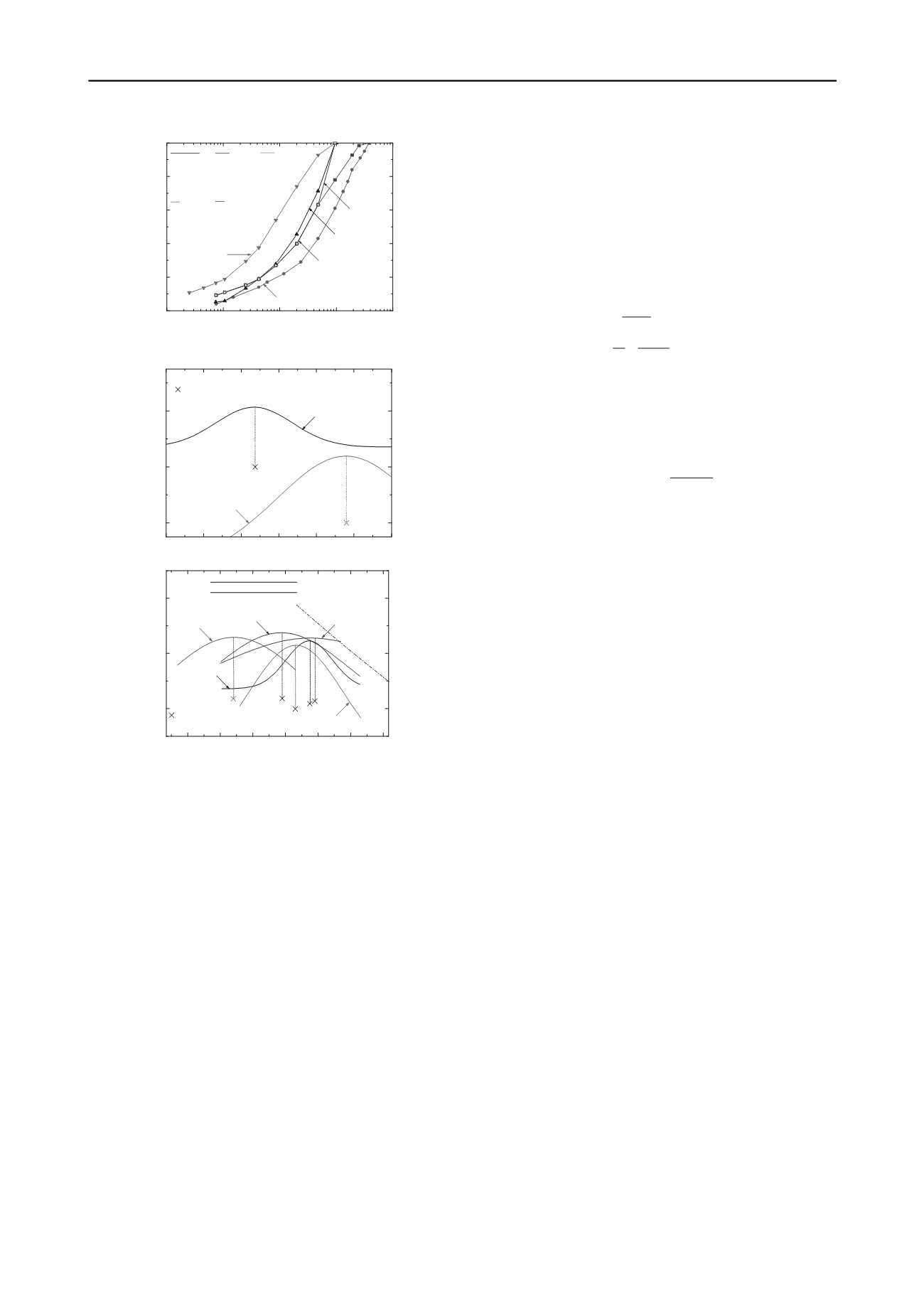

a)

5

6

7

8

9

10

11

2.0

2.1

2.2

Test conditions (w

opt

;D

c

=95%)

1.0 Ec

c/g=2.5%

4.5 Ec

c/g=4/0%

Dry density,

d

(g/cm

3

)

Sieved Chiba gravel (SCG)

water content, w (%)

b)

4

5

6

7

8

9 10

2.1

2.2

2.3

Modified Proctor (4.5E

c

)

Test conditions (w

opt

;D

c

=95%)

7.9 5.4 6.9 7.3 7.75

w

opt

(%):

p

d_max

(

g/cm

3

)

:

water content, w (%)

Dry density,

d

(g/cm

3

)

OBG

PG

CG

OBG OKG CG PG SAG

2.22 2.23 2.23 2.21 2.22

SAG

OKG

Figure. 2. Compaction curves: a) SCG for 1.0Ec & 4.5 E

c

and c/g= 2.5%

& 4/0 %; and b) five cement-mixed gravelly soils presented in Fig. 1 for

4.5Ec and c/g= 4.0% (except for PG and OKG)

Fig. 3 presents the development of the compressive strength

q

max

at confining pressure of 20 kPa with the period of initial curing

under the atmospheric pressure at a constant water content (the

same as prepared) of four kinds of SCG specimen prepared under

different conditions (1.0E

c

or 4.5E

c

and

c/g

=2.5 or 4.0 %). The

following trends can be noted. Firstly, the

q

max

value increases

considerably with time, which should be due to the cement

hydration process. The increase until a curing period of 14 days

is rather proportional to the “initial” value at 7 days.

Secondly,

the

q

max

value is largely different among the four kinds of

specimen (up to a factor of 100 %). Thirdly, the effects of

compacted dry density

ρ

d

on the

q

max

value when

c/g

= 2.5 % are

significant. An increase more than 100 % results from an

increase in

ρ

d

of only about 5 % associated with an increase in

the compaction level from 1E

c

to 4.5E

c

. On the other hand, when

the compaction level is 1.0E

c

, the

q

max

value increases by a factor

of only about 40 % with an increase in

c/g

from 2.5 % to 4. 0%

(i.e., an increase of about 60 %).

E

c

and

c/g

are the parameters commonly used in practice,

because they are easily measured and controlled. However, they

are not the basic parameters that control the strength and

deformation characteristics of CMG. This feature can be easily

seen from the following inherent drawbacks (Watanabe et al.

2003, Kongsukprasert et al. 2005). Firstly, with materials having

different specific density

s

, for the same c/g value and the same

soil void ratio, the volume of cement per volume increases with

an increase in

s

, despite that

s

has no direct effect on the stress-

strain properties. Secondly, the effect of compaction level for the

same

c/g

value (and same

s

) has two components: 1) a better

interlocking among soil particles with a decrease in the soil void

ratio; and 2) a larger amount of cement in a less volume of the

total void of soil particle skeleton. Based on this consideration,

two independent parameters are postulated: the soil skeleton

porosity

n

s

(representing the structure of the skeleton of gravelly

soil particles only); and the cement void ratio

C

r

(representing

the fraction of the void of the soil skeleton occupied by cement):

s

s

V V n

V

(1)

c

c

r

v

s

V V

C

V V V

(2)

where

V

is the total volume;

V

s

is the volume of gravelly soil

particles;

V

v

is the volume of the void of the skeleton of gravelly

soil ; and

V

c

is the volume of cement.

Ezaoui et al. (2011) also proposed the following hyperbolic

function for the

q

max

value that increases with time and is a

function of these two parameters independently:

max

0

.

1

r c

c

s

c

a C t

q t

q n

b t

(3)

where

t

c

is the curing period;

q

0

is the initial compressive

strength (when

t

c

= 0) that decreases with

n

s

;

a

is the parameter

showing the cementation effect that increases with

C

r

; and

b

is

the constant parameter that depends on cement type. The

functions

a

(

C

r

) and

q

0

(

n

s

) are obtained based on the data

presented in Fig. 3 together with those from CD TC tests on

rotary core samples retrieved from the field, as shown below.

Three solid lines presented in Fig. 4 denote the iso-strength lines

for constant

q

max

=

q

1

,

q

2

and

q

3

at a specified

t

c

according to Eq.

(3) with known values of

q

0

,

a

and

b

. The dash-dot curves are the

corresponding

c/g

= constant curves. From such a plot as shown

in Fig. 4, the most suitable (i.e., the most cost-effective)

combination of (

C

r

;

n

s

) of a given type of CMG that achieves a

given required compressive strength can be chosen referring to

the cost for cement and compaction work.

2.2

U tests on specimens made using a material use

in the field

The use of CMG is now spreading in Japan, particularly to

construct bridge abutments for high speed train lines. Very

recently, a geosynthetic-reinforced soil (GRS) integral bridge

was constructed. The backfill immediately behind the facing is

well-compacted cement-mixed gravelly soil. The grading curve

of this backfill material (i.e., crushed gravel from a quarry,

denoted as the Original Kikonai Gravel, OKG) is presented in

Fig. 1. The compaction curve for 4.5E

c

is presented in Fig. 2b.

Before the construction, to determine the cement-mixing

proportion, a series of U tests were performed on specimens

mixed at c/g = 2.0, 4.0 and 6.0 %, compacted to

D

c

=

95 % at

w=

w

opt

(4.5E

c

) and cured for 7 and 28 days. To accommodate the

maximum particle size of 37.5 mm, large specimens (150 mm in

diameter and 300 mm in height) have been used.

To apply Eq. (3) to the data from these U tests,

b

=19.62 was

used, which was obtained by analyzing a data set from a series of

CD TC tests on cement-mixed SCG cured for a period of 1 ~ 180

days (Ezaoui et al., 2010, 2011). The values of

a

(

C

r

) and

q

0

(

n

s

)

for the three

c/g

values and the two curing periods were

determined from the reported values of

q

max

(

t

c

). They are plotted

against their corresponding

n

s

and

C

r

values in Figs. 6a and b

(round symbols). In so doing, to eliminate possible effects of

specimen size and grading characteristics (discussed in the next

section), these

q

max

values had been corrected to become the

same values as those obtained for the smaller specimen (i.e., the

data presented in Fig. 3) under the same test conditions (i.e., a

curing period of 7 days;

D

c

= 95 %; and

c/g

= 4.0 %). Then, in

Figs. 6a and b, only relative variations of

q

0

and the parameter

a

due to variations in the

n

s

and

C

r

values among those U test