331

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3

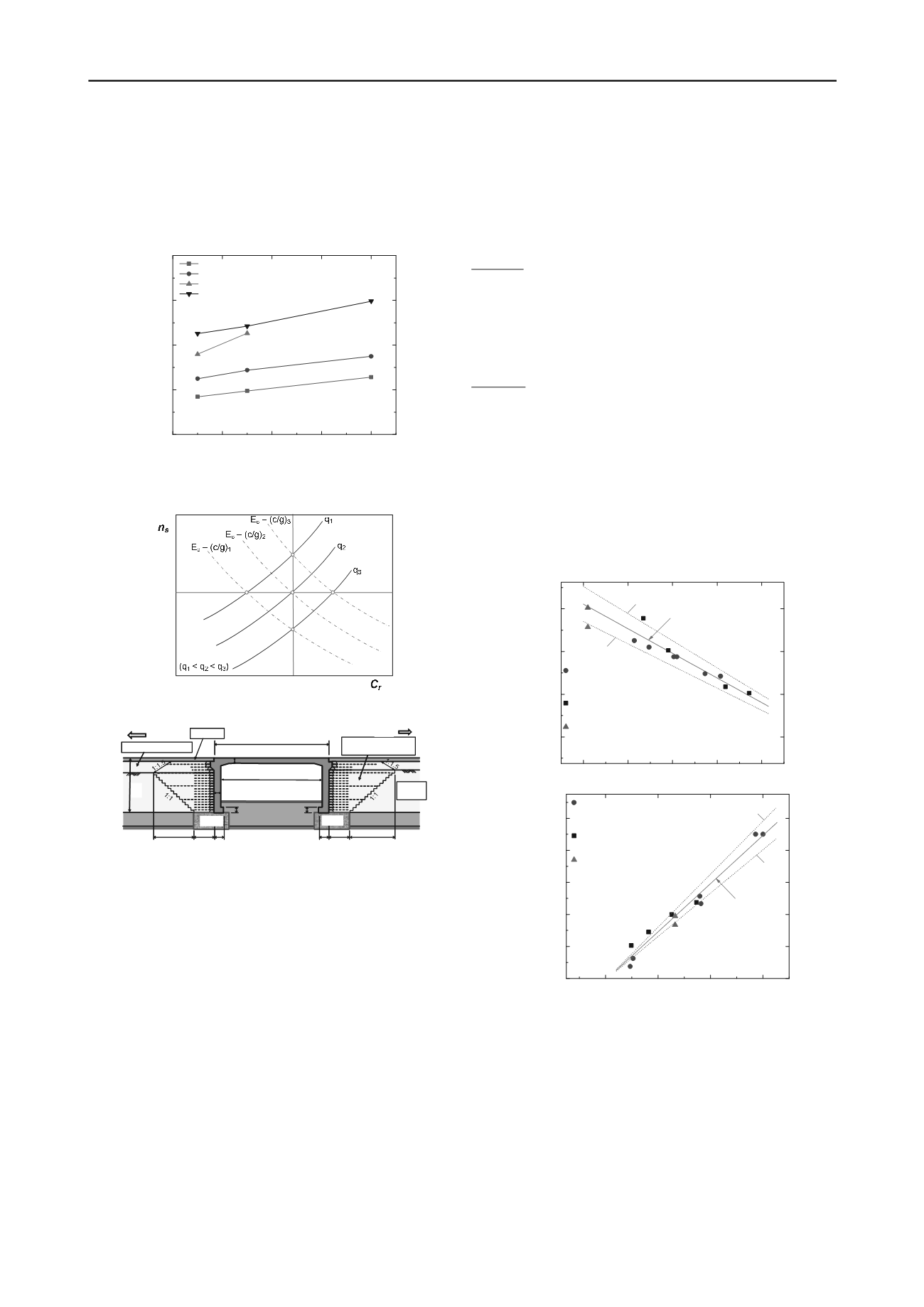

specimens are highlighted. In these figures, the data points of

SCG (square symbols) obtained from the data presented in Fig. 3

are also presented. It may be seen that these two sets of data,

which are for the specimens compacted to the same

D

c

(i.e., 95

%) at the respective optimum water contents, are consistent with

each other. Linear functions can be fitted to the

q

0

-

n

s

and

a

- C

r

relations with a small variance less than 10 %.

6

8

10

12

14

0.0

2.0

4.0

6.0

8.0

Cement mixed Chiba gravel (SG) -

h

'=20kPa

Maximum deviator stress, q

max

(MPa)

Time, t

c

(days)

1Ec / 2.5%

1Ec / 4.0%

4.5Ec / 2.5%

4.5Ec / 4.0%

*

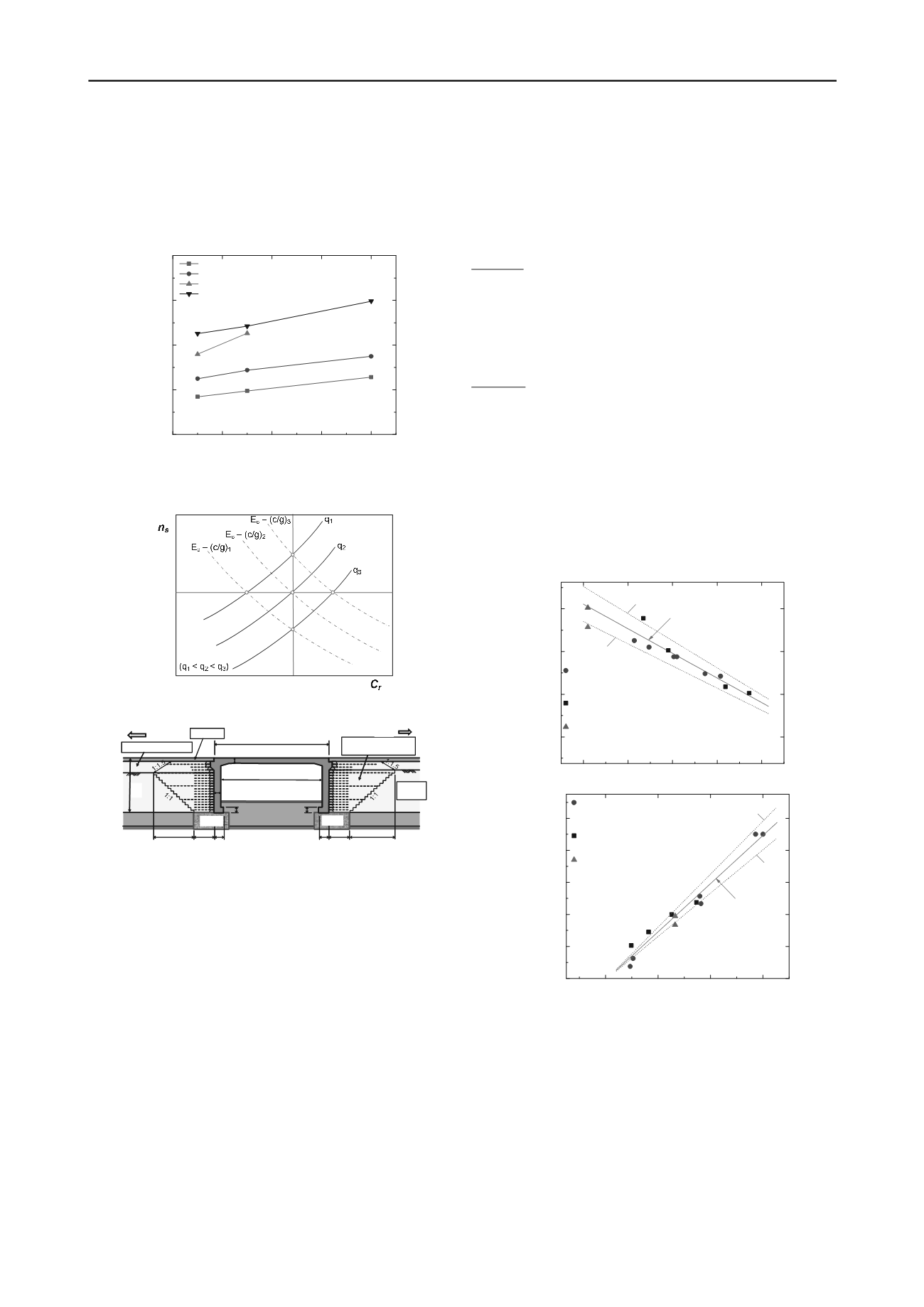

Figure 3. Development of compressive strength

q

max

with time

t

c

for

different cement contents

c/g

and different compaction energy levels

E

c

(laboratory specimen of Sieved Chiba Gravel, SCG)

Figure 4. Illustration of the effect of skeleton porosity

n

s

and cement void

ratio

C

r

on the compressive strength

q

max

=q

1,2,3

GCM: Ground improvementby cement-mixing

4.2

2.2

1.0

4.5

2.2

1.0

0.7

0.7

[Allunits in m]

GCM

Road surface

12.0

GCM

GL= 5.0

Original

ground

Backfill(uncemented)

Backfill(cement-mixed

gravelly soil)

6.1

10.75

East

West

RC slab

0.6

0.6

Figure 5. General structure (the width= 11.7 m) of the first prototype

GRS integral bridge, for the new bullet train line at Kikonai, the south

end of Hokkaido (by the courtesy of the Japan Railway Construction and

Technology Agency), constructed in 2011 (Tatsuoka et al., 2012)

2.3

TC tests on core samples retrieved from the field

It is examined below whether the empirical relations shown in

Figs. 6a and b can be applied to the data from CD TC tests on

rotary core samples retrieved from the CMG backfill of the GRS

integral bridge (Fig. 5). The backfill was compacted to

D

c

= 100

% (4.5Ec), higher than the laboratory-prepared specimens

analyzed above, and at

c/g

= 3.0 %. The core samples were 80

mm in diameter and 160 mm or less in height. The

q

max

values

evaluated by CD TC tests at confining pressure of 20 kPa are

plotted against

t

c

(from the time of compaction in the field until

respective TC tests) in Fig. 7. The data exhibit a large scatter,

which is inevitable with such core samples from the field (e.g.,

Taheri et al., 2012). Yet, the trend that

q

max

increases with

t

c

is

obvious. It may also be seen that, even at a relatively low

c/g

(=

3.0 %), the strength tends to exceed 10 MPa after

t

c

= three

months, which is a nearly half of the strength of ordinary

concrete. This property should be due to very high compaction

(i.e.,

D

c

= 100 % (4.5Ec) with

ρ

d

~ 2.23 g/cm

3

) achieved by field

compaction. It is to be noted that very high stiffness values were

measured with the two core samples cured for about 90 days

presented in Fig. 7. That is, the small-strain Young modulus (at

the isotropic stress-state) was about 35 GPa, which is the same

order of magnitude as ordinary concrete. With these core

specimens,

n

s

= 20.2 % and

C

r

= 9.3 % were obtained from

d

=

2.23 g/cm

3

and

c/g

= 3.0 %. Based on the respective linear

relations presented in Figs. 6a and b, the parameters

q

0

and

a

for

Eq. (3) were evaluated by two methods:

Method 1): By substituting

n

s

= 20.2 % into the linear relation in

Fig. 6a,

q

0

= 1.61 MPa is obtained (i.e., a data point of triangular

symbol 1), located on the linear relation). Then, by assuming the

same coefficient

b

=19.62 as the laboratory-prepared specimens

for Eq. (3) and using this

q

0

value, an average relation is best-

fitted to the data presented in Fig. 7. Then,

a

= 6.7 % is obtained

for

C

r

= 9.3 % (i.e., a data point of triangular symbol 1) in Fig.

6b).

Method 2): By substituting

C

r

= 9.3 % into the linear relation

shown in Fig. 6b,

a

= 7.7 % is obtained (i.e., a data point of

triangle symbol 2), located on the linear relation). Then, by

assuming

b

= 19.62 as above for Eq. (3) and using this

a

value, an

average relation is best-fitted to the data presented in Fig. 7

(which is eventually the same as the one obtained by Method 1)).

Then,

q

0

= 1.43 MPa is obtained for

n

s

=20.2 % (i.e., a data point

of triangular symbol 2) in Fig. 6a).

As seen from Figs. 6a and b, the results obtained by two methods

are consistent. The results shown above indicate that Eq. (3) is

relevant for various kinds of CMGs with different grading

characteristics, different cement contents (c/g= 2.0 ~ 6.0 %) and

a relatively wide range of compaction level (

d

= 2.0 ~

2.23 g/cm

3

).

a)

0.20 0.22 0.24 0.26 0.28

0.4

0.8

1.2

1.6

2)

-10%

OKG (Kikonai) - 4.5E

c

(D

c

=95%)

(c/g=2.0, 4.0 and 6.0%)

Specimen prepared in the laboratory

SCG - 1.0/4.5Ec (D

c

=95%)

(c/g=2.5 and 4.0%)

OKG (Kikonai) - 4.5E

c

(D

c

=100%)

(c/g=3.0%)

Two deduced data 1) & 2)

from TC tests on rotary core samples from the site

Parameter q

0

(MPa)

Porosity of squeleton, n

s

(%)

Linear fitting

+10%

1)

b)

4

8

12

16

0

4

8

12

16

20

+10%

OKG (Kikonai) - 4.5E

c

(D

c

=95%)

(c/g=2.0, 4.0 and 6.0%)

(specimen prepared in the laboratory)

SG (Chiba) 1.0/4.5Ec (D

c

=95%)

(c/g=2.5 and 4.0%)

OKG (Kikonai) - 4.5E

c

(D

c

=100%)

(c/g=3.0%)

Two deduced data 1) & 2)

from TC tests on rotary core

samples from the site

Parameter a(C

r

)

Cement void ratio, Cr (%)

Linear fitting

-10%

1)

2)

Figure 6. a) Variation of parameter

q

0

, Eq. (1), with skeleton porosity

n

s

and; b) variation of parameter

C

r

, Eq. (1) with cement void ratio

C

r

3 EFFECTS OF SPECIMEN AND PARTICLE SIZES

The compressive strength at given confining pressure is also

controlled by factors other than those analyzed in the section

above, including: grading characteristics, such as the mean

diameter

d

50

and the uniformity coefficient, fines content etc.

(factor G); and the size of specimen (factor S) (Ezaoui et al.,

2011). Two relevant parameters, among others, for factor S are:

i) the particle/specimen size ratio (represented by the ratio of the

specimen diameter

D

to

d

50

); and; ii) the specimen volume

V

.