314

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The preparation of the samples considered the following

steps: 1) drying the complete sample; 2) sieving the entire

sample; 3) separation of the fines (<0.074 mm) and coarse

(>0.074 mm) fractions; 4) preparation of the sample with the

fines content predefined by project. The probes were

compacted in layers to an initial density representative of the

expected in-situ compaction, with the tamping method and with

moisture close to optimum (± 2%, according to Standard

Proctor).

3 UNDRAINED SHEAR STRENGTH (S

U

)

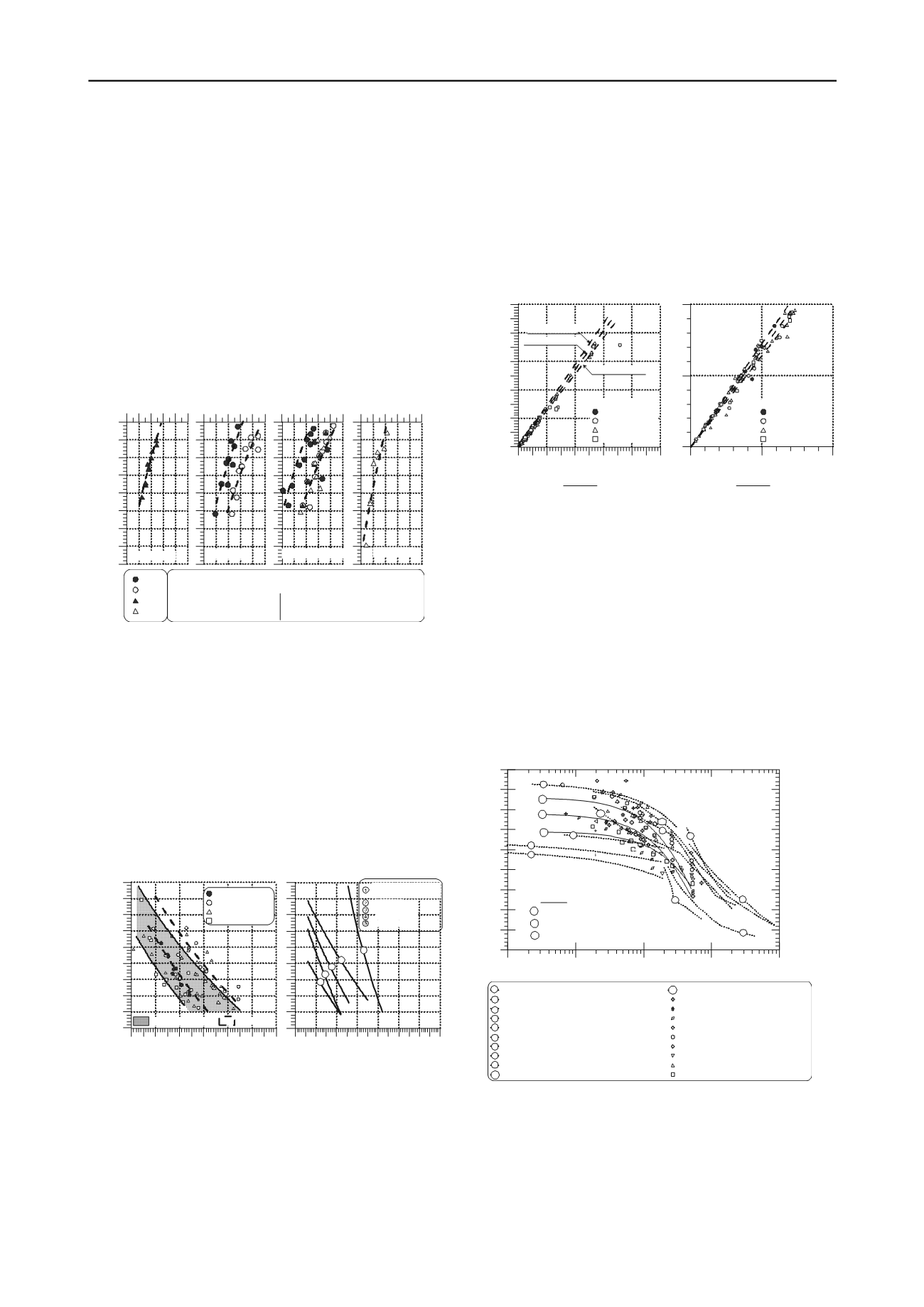

Figure 1 presents the variation of Su for the different sands as a

function of the void ratio (e) and the fines content. It is

important to note that the void ratio (e) indicated correspond at

the end of consolidation phase.

0.5 0.7 0.9

Void ratio (e)

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

Su (MPa)

12% Fines

0.5 0.7 0.9

Void ratio (e)

15% Fines

0.5 0.7 0.9

Void ratio (e)

S1

S2

S3

S4

18 to 21% Fines

0.5 0.7 0.9

Void ratio (e)

30% Fines

Best Fix Curve: Su=-C. ln(e)-D

12% Fines: C=3.50 D=0.85

15% Fines: C=2.94 D=0.59

C=2.94 D=0.074

18% to 21% Fines: C=2.62 D=0.78

C=2.62 D=0.112

30% Fines: C=4.18 D=1.40

Figure 1. Summary of undrained shear strength (Su) variation.

Figure 2a presents the variation of Su as a function of the void

ratio and Figure 2b presents the average tendency curves for all

samples tested. A tendency of Su to decrease as the fines

content increases was observed. In addition, and as reference, in

these figure 2b results obtained from the Toyoura Sand

(fines=0%), tested by Verdugo (1992) in a wide range of

relative density (DR=7% to 67%) have been included.

The variation of the undrained shear strength with the fines

contents estimate a value of zero for Su for average values of

e=0.72 (30% and 18-21% of fines), e=0.89 (15% of fines) and

e=0.78 (12% of fines). For the different sands tested, these void

ratios are associated to relative densities lower than DR<40%.

In the Toyoura Sand, Verdugo (1992) recorded zero values of

Su for values of DR<15%.

0.5 0.6 0.7 0.8 0.9 1 1.1

Void ratio (e)

-0.2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

Su (MPa)

Sands12%Fines

Sands15%Fines

Sands18-21%Fines

Sands30%Fines

0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

Void ratio (e)

ToyouraSand,0%Fines

Verdugo (1992)

2

3

4

5

12%Fines

15%Fines

18 to21%Fines

30%Fines

18% to 21% Fines

15% Fines

1

Figure 2. Variation of undrained shear strength (Su) with the void ratio

(e) and the fines content. Sand samples S1 to S4. (Campaña, 2011)

4 DRAINED SHEAR STRENGTH

The shear strength envelopes in the (q-p’) plane for CID triaxial

tests are presented in summary form on Figure 3. Values of

residual strength obtained in the CIU tests (Su) were also

included. In spite of the wide range of fines content in the four

samples tested, the shear strength envelopes obtained are

similar. For

’

3

<1 MPa, it are characterized by internal friction

angles (

) between

=32° and

=36°; for

’

3

>1 MPa, the

internal friction angles vary between

=32° to

=34°. No strong

reduction in the strength envelope at high pressures was

observed, this behavior is in contrast with the one observed with

the Sacramento Sand reported by Lee & Seed (1967). The little

quantity of particles crushing that is produced in the tailings

sands with the increase of confinement could be explained this

unexpected behaviour. This evidence was observed

systematically in the grain size tests performed before and after

each triaxial test (Campaña et al., 2007).

0 2 4 6 8 10

p'=

�

'

1

+2

�

'

3

3 (MPa)

0

2

4

6

8

10

q=

�

'

1

-

�

'

3

(MPa)

CIU and CID Test

Sands12%Fines

Sands15%Fines

Sands18-21%Fines

Sands30%Fines

0

1

2

p'=

�

'

1

+2

�

'

3

3 (MPa)

0

1

2

CIU and CID Test

Sands12%Fines

Sands15%Fines

Sands18-21%Fines

Sands30%Fines

a)

b)

M=1.45 (

�

=36°)

M=1.36 (

�

=34°)

M=1.36 (

�

=32°)

Figure 3. Drained and undrained residual strength curves.

a) all the tests, b) detail for

’

3

<2 MPa.

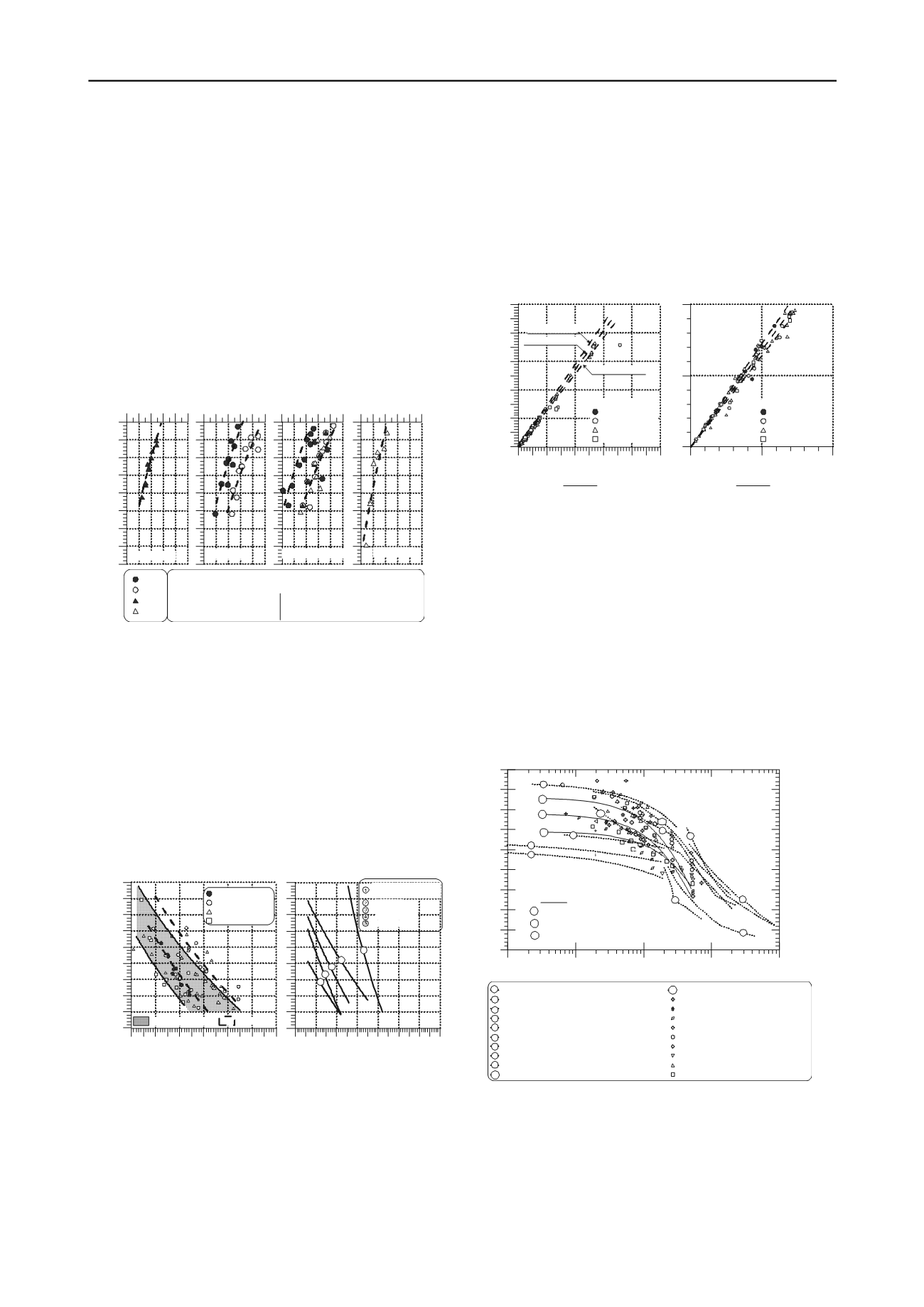

5 CRITICAL STATE OR PERFECT PLASTICITY

Although the ultimate state (steady state) has not clearly

reach in all the tests, by plotting the final results in the graph (e-

log p’), it can be observed that the results allow to mark off with

a reasonable precision the combination of density and

confinement pressure that determine that the sands present a

contracting or dilating behavior. By comparing the results of

this study with the ones reported in the technical literature, the

obtained behavior of tailing sands is in accordance with other

natural sands of similar mineralogy. These results allow to

extrapolate the behavior of tailings sands at higher confining

pressures and estimate that these would not present an important

decrease in the shear strength. Figure 4 presents all the tests,

compared with several results of other sands.

0.01

0.1

1

10

100

p'=(

�

'

1

+2

�

'

3

)/3 (MPa)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Void Index,e

Toyoura Sand (Ishihara 1993)

Loose Toyoura Sand (Mioura & Yamanouchi, 1975)

Dense Toyoura Sand (Mioura & Yamanouchi, 1975)

Hostun Sand (Le Long ,1968 after Biarez & Bard, 1992)

Ottawa Sand, 15% F (Murthy et al 2007)

Ottawa Sand, 10% F (Murthy et al 2007)

Ottawa Sand, 5% F (Murthy et al 2007)

Drained Cambria Sand (Yamamuro & Lade, 1996)

Undrained Cambria Sand (Yamamuro & Lade, 1996)

Dense Sacramento Sand (Lee & Seed, 1967)

Loose Sacramento Sand (Lee & Seed, 1967

S1 15%F

S1 18%F

S1 21%F

S2 15%F

S2 21%F

S3 12%F

S3 18% F

S4 20% F

S4 30% F

1

2

4

5

6

10

1

8

9

7

3

11

2

3

4

5

6

7

8

9

10

11

12

12

Best Fit

Sand S1, 15% Fines

13

13

Sand S3, 18% Fines

14

14

Sand S4, 30% Fines

Figure 4: Results of triaxial tests in the e-log p’ plane.

6 DEFORMATION MODULI, E

I

(

~10

-3

)

To determine the variation of the initial tangent deformation

moduli (Ei) at large deformations with the confining pressure, a

hyperbolic adjustment (Duncan et. al, 1970) was performed,

which was applied both for drained as well as for undrained

triaxial tests. The variation of the deformation modulus (E

i

) as