304

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The results also suggest that SMA has a lower residual

strength than DAC once the aggregate structure is disturbed at

slow rates of loading. This is in direct contradiction to how the

SMA product is supposed to perform at high rates of loading,

which is to have better resistance to permanent deformation.

This difference in behaviour at higher loading rates could be

related to the much greater sensitivity of the SMA to changes in

loading rate which has been observed in the triaxial tests. This is

also consistent with the greater influence of the bitumen in the

SMA tests than for the DAC.

-0.040

-0.030

-0.020

-0.010

0.000

0.010

0.020

0.030

0

0.05

0.1

0.15

0.2

0.25

0.3

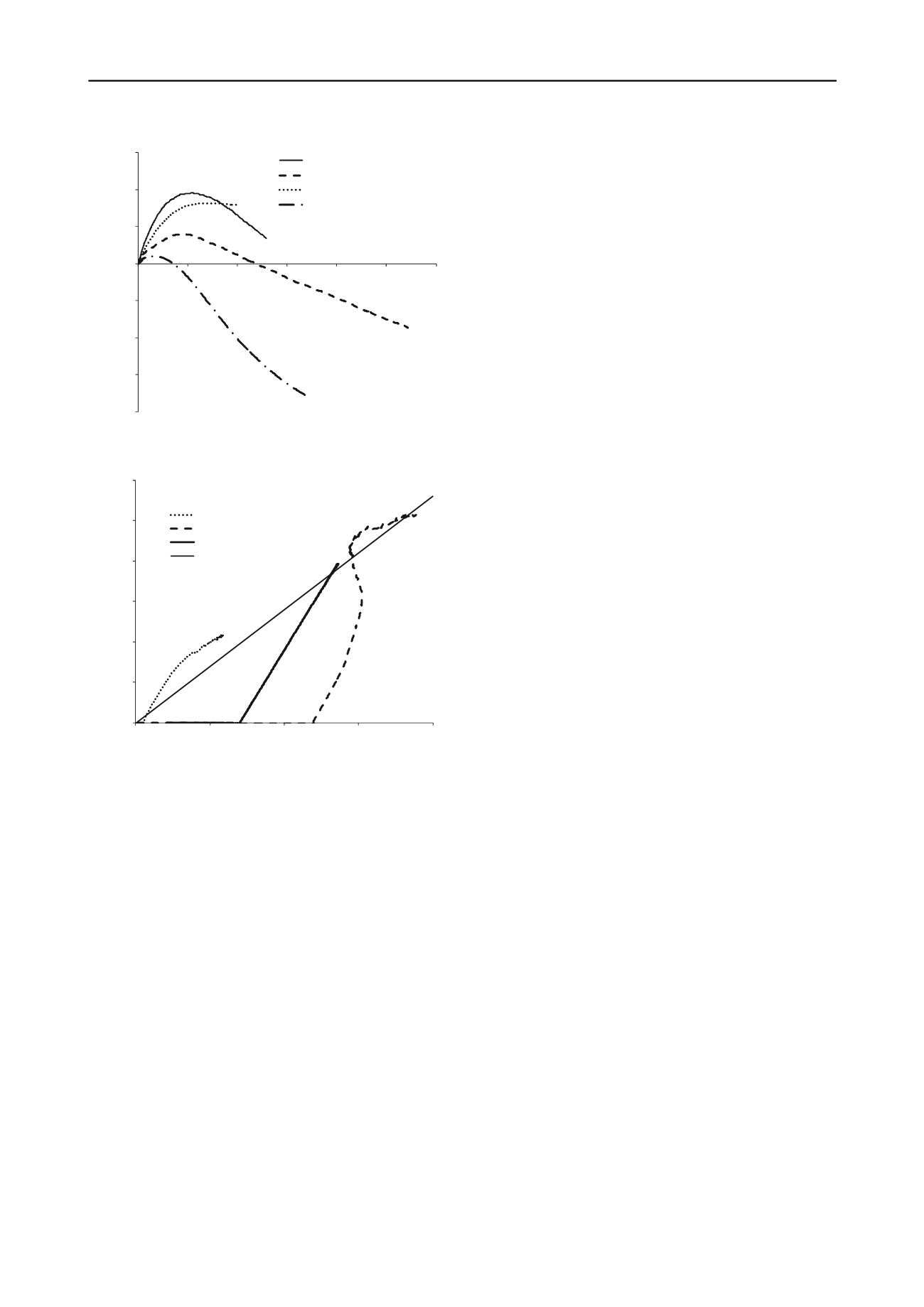

Volume strain

Axial strain

SMAaggregateonly,p'c = 500 kPa

SMAp'c = 700 kPa

DAC aggregateonly,p'c = 500 kPa

DAC p'c = 700 kPa

3 CONCLUSION

Conventional soil mechanics triaxial tests have been conducted

on saturated asphalt specimens. These have shown that the

behaviour of the asphalt can be very sensitive to details of the

aggregate grading. For dense asphaltic concrete, which has a

well-graded aggregate and 5% bitumen, the behaviour in slow

triaxial tests is controlled by the aggregate particles, and the

bitumen appears to have little effect. For the stone mastic

asphalt, which has a gap-graded aggregate and 6% bitumen, the

bitumen has a significant effect on the stress-strain-strength

behaviour.

Figure 7. Comparison of volume changes for SMA and DAC.

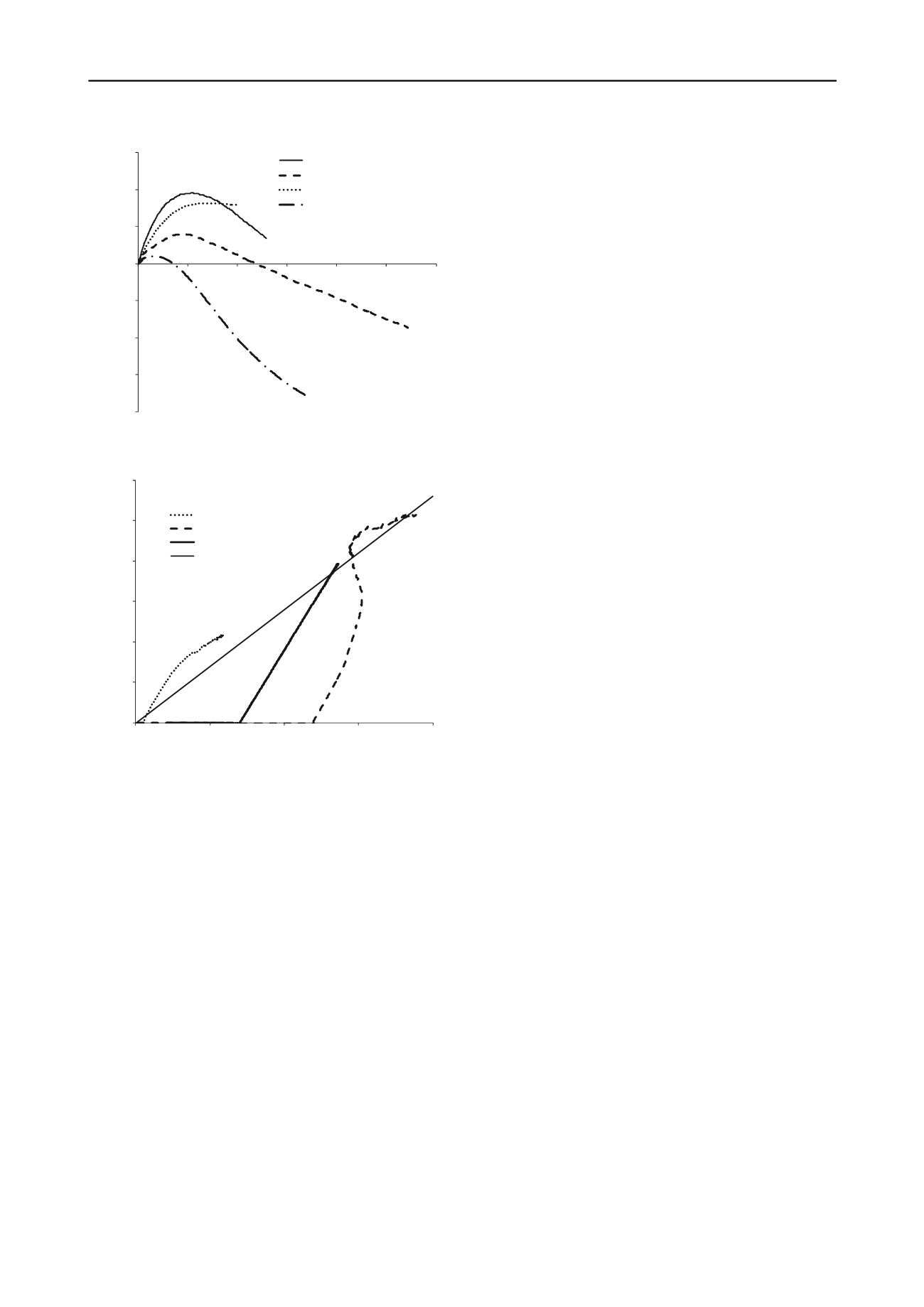

0

500

1000

1500

2000

2500

3000

0

500

1000

1500

2000

Deviator stress, q (kPa)

Mean effective stress, p' (kPa)

Undrained p'c=50 kPa

Undrained p'c=1200kPa

Drained p'c= 700kPa

M= 1.4

The sensitivity of the asphalt to relatively minor changes in

grading and bitumen content is a surprising result, and further

tests are in progress to help understand the mechanisms

responsible for this behaviour.

4 ACKNOWLEDGEMENTS

The authors are grateful to the Roads and Maritime Services

(NSW) for supplying the asphalt specimens and materials used

in this study.

5 REFERENCES

Antes, PW, Van Dommelen, AE, Houben, LJM, Molenaar, AA and

Parajuli, U (2003) Stress dependent behaviour of asphalt mixtures

at high temperatures,

Proceedings of the Technical Sessions

, v 72,

p 173-195,

Asphalt Paving Technology

.

Figure 8. Effective stress paths of SMA specimens.

similar aggregate void ratios. Although the lower strength of the

SMA specimen is consistent with the reduced dilation, this does

not explain the very much lower mobilized frictional resistance

of the SMA specimen, which can be seen from the plot of the

effective stress paths of the drained test, and two undrained tests

of SMA, shown in Figure 8. Figure 8 shows the mobilized stress

ratio for the tests at the higher stress levels is 1.4, corresponding

to a friction angle of 34.6

o

. This is significantly less than the

friction angle of the aggregate which is expected to be 41

o

,

similar to the DAC aggregate because the material is the same

and the grading is not that different.

Li, P, Liu, J and Saboundjian, S. (2010) Materials and temperature

effects on the resilient response of asphalt-treated Alaskan base

course materials,

Journal of Materials in Civil Engineering

, 23, 2,

p. 161-168.

Muraya, PM, Molenaar AAA and van de Ven MFC (2012)

Contribution of the bituminous mortar and stone skeleton to the

resistance to permanent deformation in Asphalt mixtures, Journal of

Testing and Evaluation, 37, 5, 1-7.

Roads and Maritime Services(RMS) (2010), R121. QA Specifications,

Stone Mastic Asphalt, Ver. 2.1 NSW , Australia.

Roads and Maritime Services(RMS) (2012) R116. QA Specifications,

Dense GradedAsphalt, Ver. 8.2 NSW, Australia.

It can be seen that the SMA specimens mobilize a

significantly lower resistance than the DAC specimens, even

though they have mostly the same aggregate material with the

same frictional characteristics. The differences between the two

asphalt materials include: the gap grading of the SMA

aggregate; the slightly higher bitumen content in the SMA; and

the presence of a small amount of cellulose fibres in the SMA

mix. The presence of fibres would be expected to provide some

additional strength to the asphalt mix, and there was no

evidence that they had a significant effect on the aggregate only

mixture, so the fibres do not appear to be responsible for the

difference in behaviour. It thus appears that in SMA the

bitumen is interacting with the fine particles and acting to

minimize the frictional interaction of the larger aggregate. In

contrast in the well graded DAC there appears to be sufficient

interaction between the larger aggregate particles so that the

bitumen acts independently of the particle structure.