303

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

variations of the aggregate void ratio are inspected it can be

seen that these also provide support for a critical state line with

gradient

= 0.056.

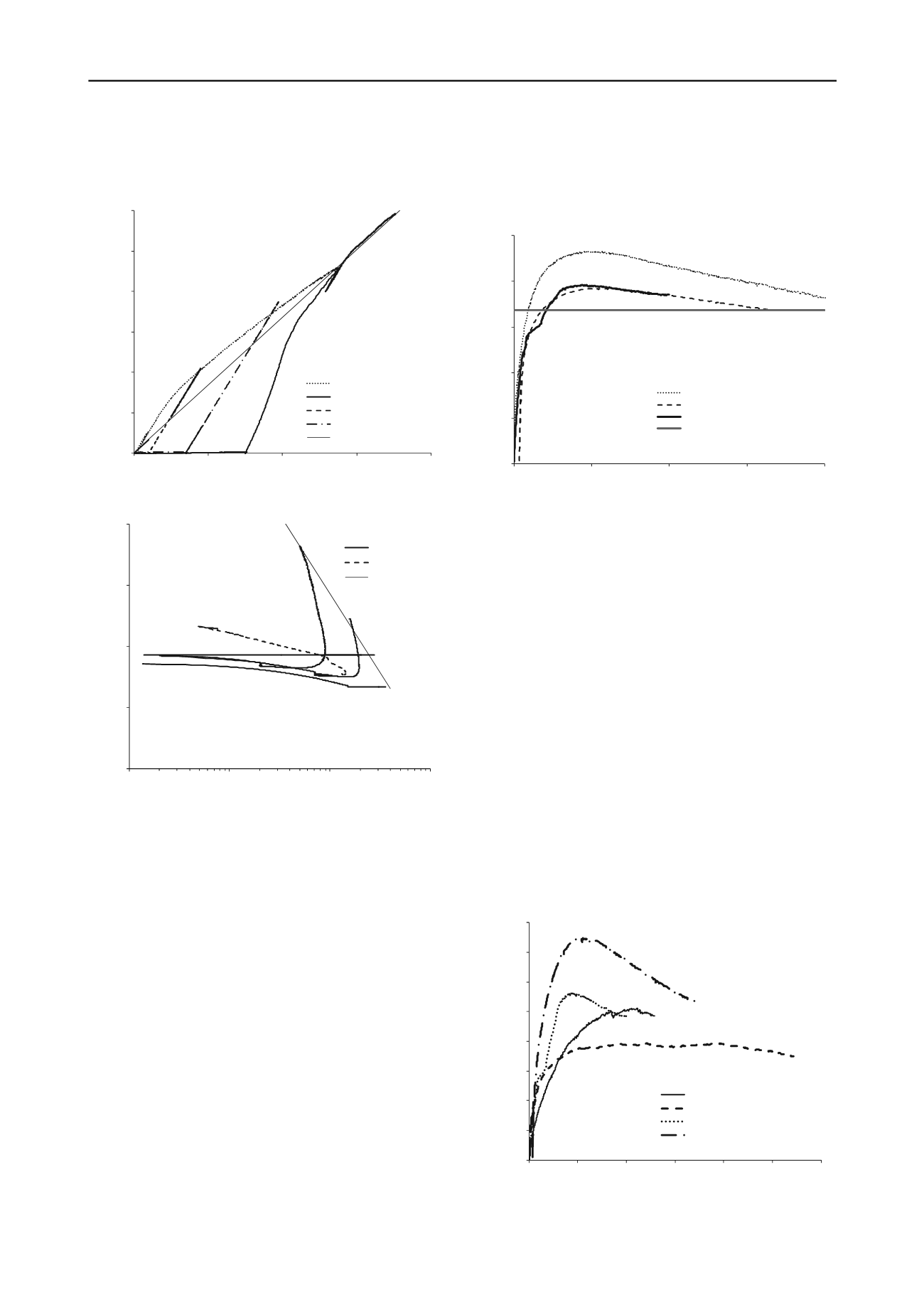

Figure 3. Effective stress paths for DAC specimens.

Figure 4. Variation of aggregate void ratio for DAC specimens.

When the test with aggregate only is plotted on Fig. 4 it

appears that it does not reach the critical state line. However,

the aggregate only specimen formed a pronounced shear plane

and ruptured the membrane, and it is believed that if the test had

continued the specimen would have expanded and approached

the same ultimate locus as the asphalt specimens. It may also be

noted that the asphalt binder resulted in more uniform

deformations being observed in all the DAC specimens, which

tended to bulge out despite their dense and dilative nature.

Because different confining stresses have been used in the

drained tests for the asphalt specimens and the specimen

without the bitumen, the test results cannot be directly

compared. An alternative approach is to compare the stress ratio

(q/p′) versus axial strain responses as presented in Figure 5.

This shows that the specimen without the binder at an effective

confining stress of 500 kPa is behaving very similarly to the

asphalt specimen at 700 kPa. As discussed previously, and

shown in Figure 4, the asphalt specimens are slightly denser and

this can explain, at least part of, the difference in the behaviour

with stress level. The similarity of the shape of the responses

also suggests that the ultimate frictional resistance of the

aggregate is similar to that of the asphalt specimens, and as

expected the frictional resistance of the asphalt is controlled by

the aggregate. The results presented in Figures 1 to 5 all suggest

that the binder has only a minor effect on the stress-strain

response of the DAC asphalt specimens. At the slow loading

rates used in these tests the bitumen is simply acting as a

viscous pore fluid, and it is viscosity is sufficiently low for it to

flow out of the way of the aggregate to aggregate particle

interactions.

0

1000

2000

3000

4000

5000

6000

0

1000

2000

3000

4000

Deviator stress, q (kPa)

Mean effective stress, p' (kPa)

Undrained p'c = 50 kPa

Undrained p'c = 1500 kPa

Drained p'c = 200 kPa

Drained p'c = 700 kPa

M = 1.68

0

0.5

1

1.5

2

2.5

0

0.05

0.1

0.15

0.2

Stress ratio q/p'

Axial strain

DAC p'c = 200 kPa

DAC p'c = 700 kPa

Aggregateonlyp'c= 500 kPa

M= 1.68

0.15

0.2

0.25

0.3

0.35

10

100

1000

10000

Void ratio

Mean effective stress (kPa)

Asphaltspecimens

Aggregateonly

Critical state line

Figure 5. Stress ratio, strain responses in drained tests.

Tests have also been conducted on Stone Mastic Asphalt

(SMA) specimens. SMA is used in pavements as it is reported

to have better resistance to rutting, and this is believed to result

from the greater contact between the larger particles of

aggregate, which occurs because of the removal of some of the

intermediate particle sizes in the grading.

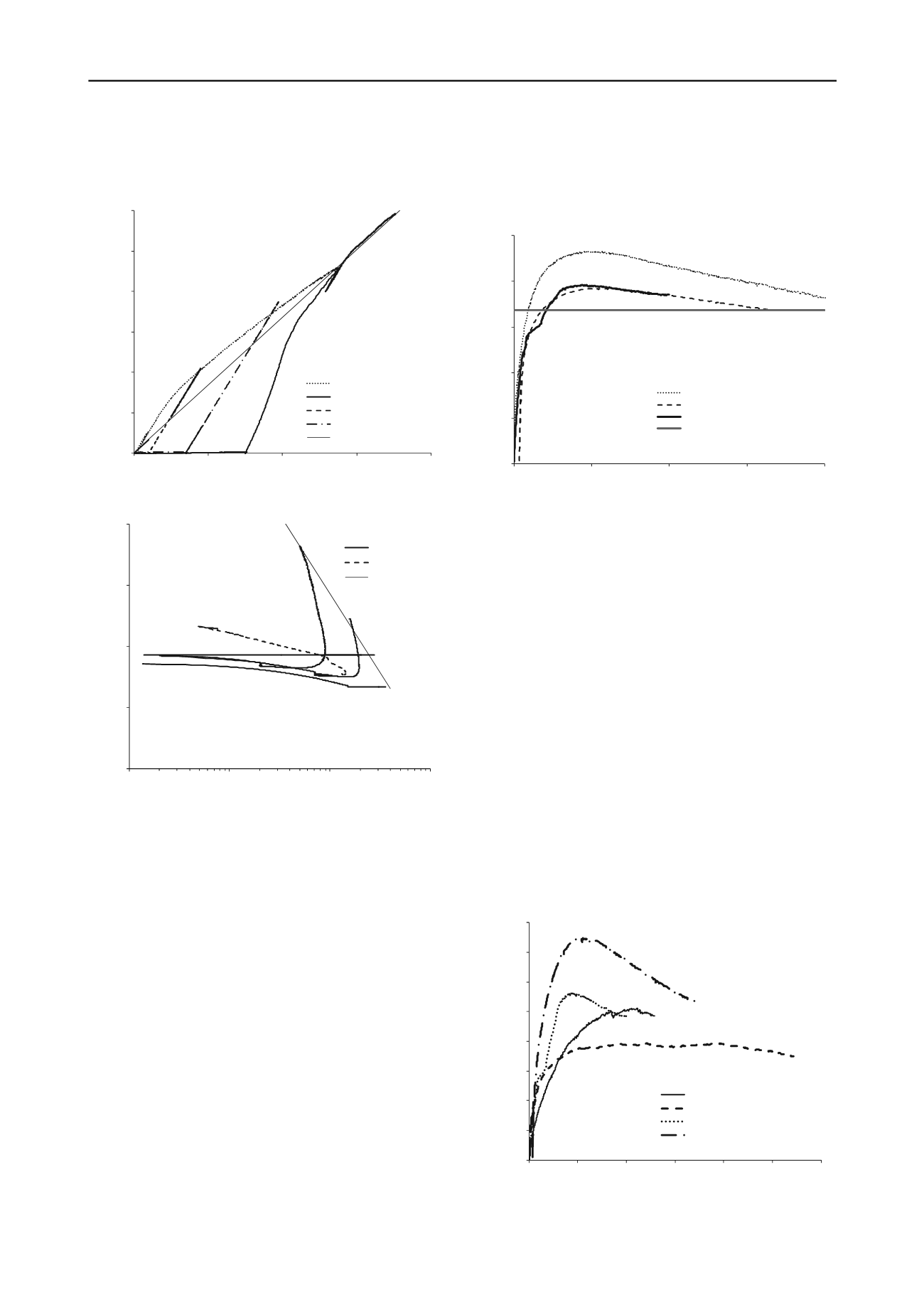

Figure 6 shows a comparison between the stress-strain

responses of the SMA and DAC specimens in drained tests.

This shows that there are significant differences between the

two asphalt materials. The SMA specimen has a peak deviator

stress only half that of the DAC specimen even though both

specimens have the same confining stress. This significant

reduction is not the result of differences in the aggregate void

ratio, which is essentially identical for the two materials, and

neither can it be explained by differences in the frictional

characteristics of the aggregate as the same aggregate is used for

both types of asphalt. However, the SMA aggregate only

specimen had a significantly higher void ratio, approximately

0.4, and this can explain why the SMA aggregate appears less

stiff and more compressible than the DAC aggregate.

Figure 7 shows the volume strains measured during the

drained tests shown in Figure 6. The DAC specimen is

significantly more dilative than the SMA specimen even though

the specimens are compacted with similar energies and with

0

500

1000

1500

2000

2500

3000

3500

4000

0

0.05

0.1

0.15

0.2

0.25

0.3

Deviator stress (kPa)

Axial strain

SMAaggregate onlyp'c = 500 kPa

SMAp'c = 700 kPa

DAC aggregate onlyp'c = 500kPa

DAC p'c = 700 kPa

Figure 6. Comparison of SMA and DAC materials in drained tests.