302

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

cylindrical specimens were then subjected to conventional CIU

and CID triaxial tests.

Table 1. Particle size distributions.

Sieve Size

DAC

(%)

SMA

(%)

19.0

100.00

100.00

13.2

99.00

90.24

9.5

83.38

50.06

6.7

66.74

30.98

4.75

56.81

24.14

2.36

39.97

20.78

1.18

27.44

17.92

0.60

20.74

15.79

0.30

11.79

13.04

0.15

7.69

11.53

0.075

5.92

10.27

Filler/Binder

1.15

1.55

Bitumen

5.17

6.64

Table 2. Mix proportions.

Aggregate

DAC %

SMA%

14mm Basalt

19.8

57.98

10mm Basalt

19.4

14.22

7mm Basalt

6.40

0.00

Basalt Dust

35.1

9.52

Benedict's

Glass Sand

13

3.27

Hydrated Lime

1.14

5.24

Finely Ground

Limestone

-

2.97

Cellulose

Fibres

-

0.28

C450 Bitumen

5.20

6.50

Additional triaxial tests have been performed on aggregate

specimens with identical gradings to the asphalt specimens,

except for the absence of the bitumen. These specimens were

100 mm in diameter by 200 mm tall, and were prepared by

tamping the moist aggregate mixture into a split mould located

on the triaxial base platen.

The asphalt specimens had nominal air voids of 5.5% and

very low permeability. To saturate the specimens elevated back

pressures of between 600 kPa to 1000 kPa were used, but even

so several days were required for the rate of water inflow to

drop below 3 mm

3

/min at which stage the specimens were

considered to be effectively saturated.

2 RESULTS AND DISCUSSION

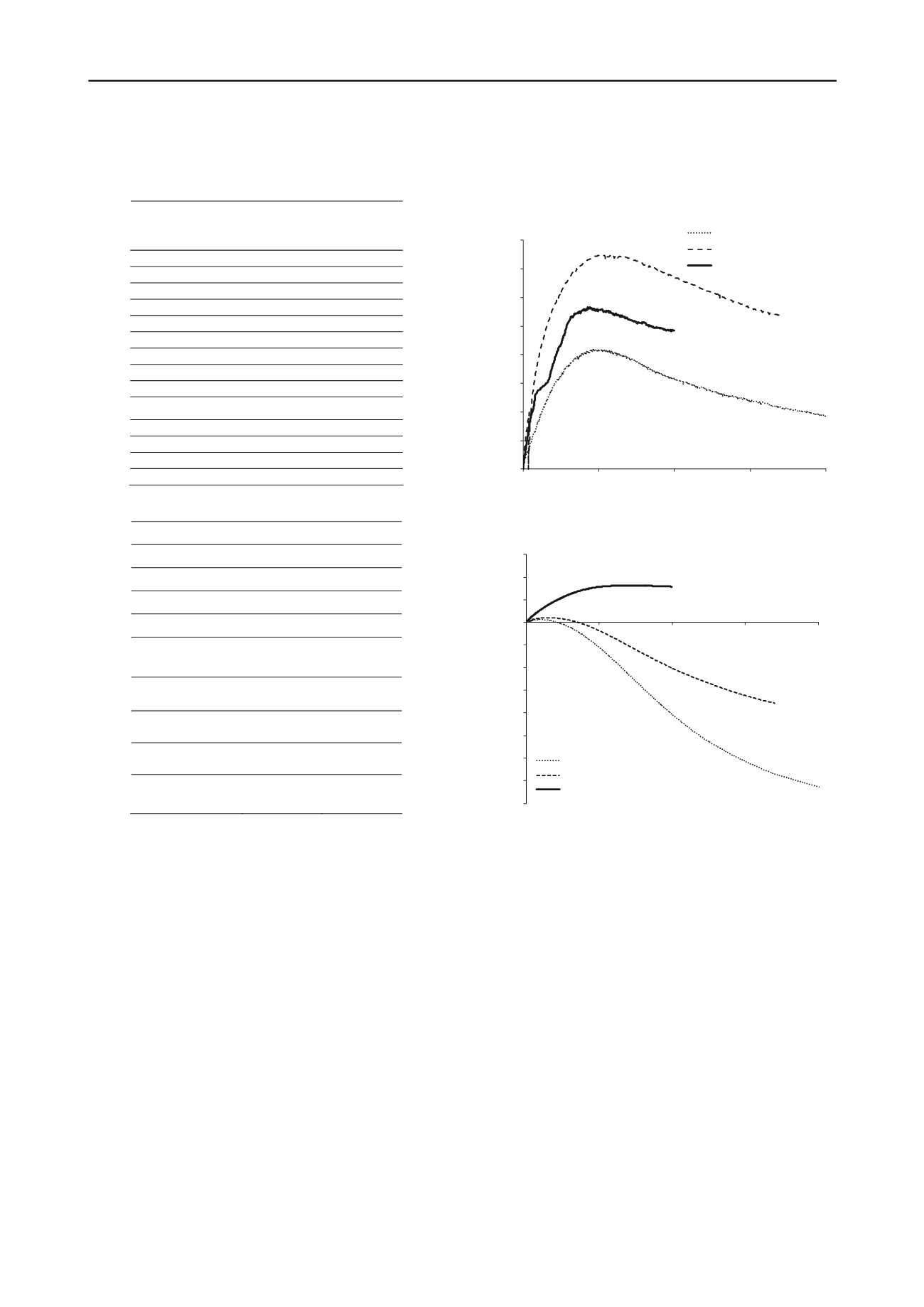

The results of drained triaxial tests on the DAC mix are shown

in Figures 1 and 2. These figures compare the response of

asphalt specimens isotropically compressed to 200 kPa and 700

kPa, with a specimen comprised only of the aggregate

compressed to 500 kPa.

Figure 1 shows that the differences between the two asphalt

(DAC) specimens and the aggregate only specimen are

primarily due to the different effective stress levels, and that the

effects of the bitumen on the stress-strain response are relatively

minor for these tests, which were conducted at a strain rate of

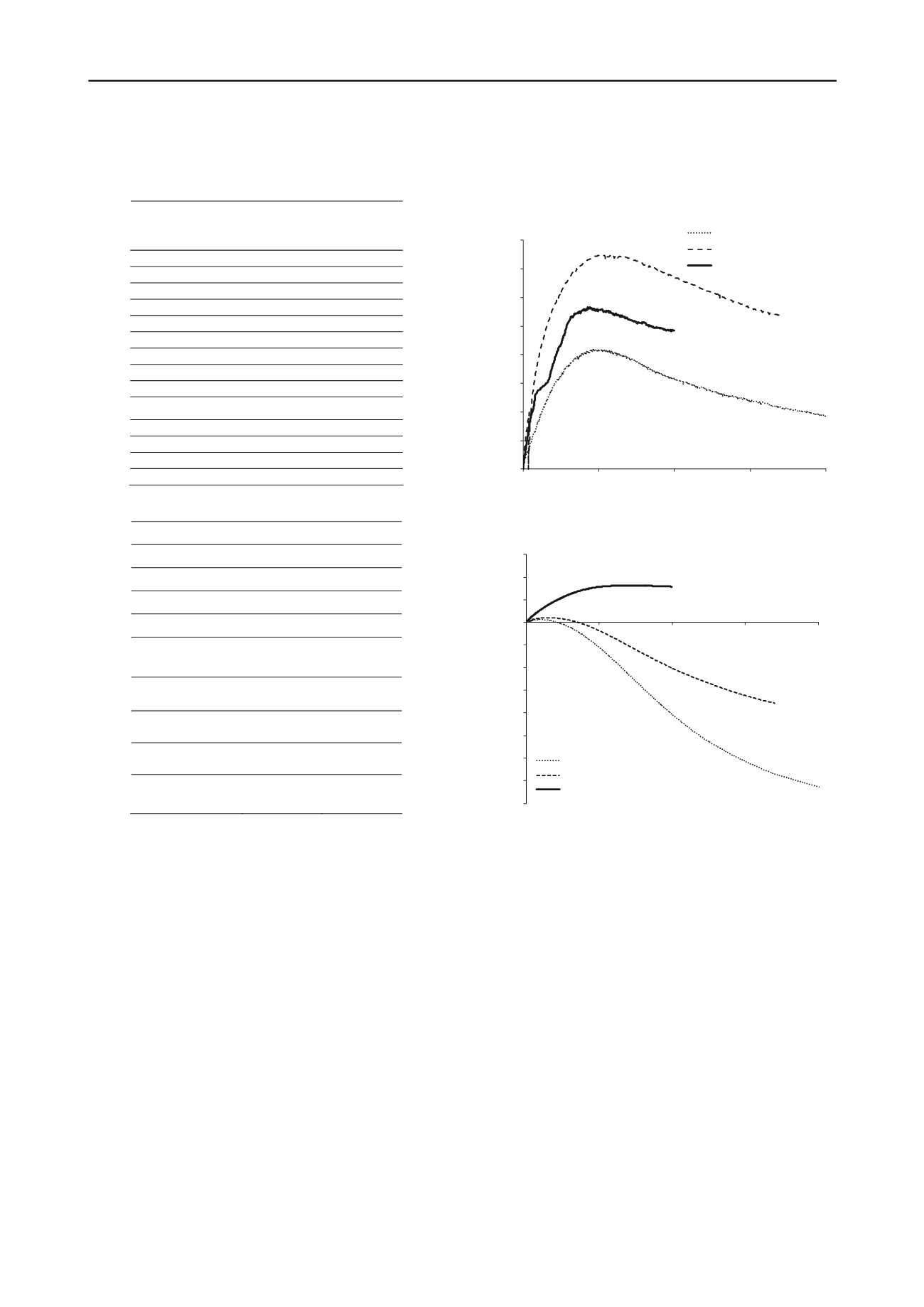

0.5%/hr. From the volume strain responses shown in Figure 2 it

is evident that the asphalt specimens are more dilative. This is a

consequence of the asphalt specimens being denser than the

aggregate only specimen.

0

500

1000

1500

2000

2500

3000

3500

4000

0

0.05

0.1

0.15

0.2

Deviator stress (kPa)

Axial strain

DAC p'c = 200 kPa

DAC p'c = 700 kPa

Aggregate only p'c = 500 kPa

Figure 1. Deviator stress, strain responses from drained tests of DAC.

-0.08

-0.07

-0.06

-0.05

-0.04

-0.03

-0.02

-0.01

0.00

0.01

0.02

0.03

0

0.05

0.1

0.15

0.2

Volume strain

Axial strain

DAC p'c = 200 kPa

DAC p'c = 700 kPa

Aggregate only p'c = 500 kPa

Figure 2. Volume strains from drained tests on DAC.

From a soil mechanics perspective the behaviour of the

asphalt might be expected to depend on the void ratio, but for

the asphalt specimens where the voids are mostly filled with

bitumen a number of definitions of void ratio can be employed.

The results presented in Figures 1 and 2 show the bitumen has

little influence on the stress- strain response which suggests that

the definition of void ratio should include the space filled by the

bitumen as well as the water. For the asphalt specimens this

results in a value of approximately 0.24 for the aggregate void

ratio, e

agg

. However, if the bitumen is included with the solids

then a much lower void ratio of 0.08 is obtained. If the bitumen

makes no contribution to the strength of the material then we

might expect to observe a unique critical state line, using the

aggregate void ratio, e

agg

, which is unaffected by the presence of

the bitumen. This is explored in Figures 3 and 4. Figure 3 shows

the effective stress paths in deviator stress,

q

, versus mean

effective stress,

p′

, from several asphalt specimens subjected to

both drained and undrained tests, and Figure 4 shows the

resulting changes in aggregate void ratio. It can be observed that

the asphalt specimens behave as expected for dense granular

materials, with significant dilation at low effective stresses and

with the effects of dilation diminishing as the effective stress

level increases. All specimens approach a unique critical state

line described by M = 1.68, a friction angle of 41

o

. When the