235

Creep characteristics of clay in one-dimensional compression with

unloading/reloading cycles

Propriétés de fluage des argiles en compression unidimensionnelle avec cycles de

charge/décharge.

Kawabe S., Tatsuoka F.

Tokyo University of Science, Japan

ABSTRACT: One-dimensional compression tests including sustained loading stages were performed on reconstituted specimens of

two types of clay. In some tests, a number of sustained loading tests were performed during otherwise multiple unloading/reloading

cycles with relatively large stress amplitudes. The creep strain taking place at respective sustained loading stages is a function of the

ratio of the current sustained loading stress to the stress at which the latest reversal of loading direction was made, independent of

previous loading history and current sustained loading stress. A new laboratory one-dimensional compression test method is proposed

to evaluate the creep process at such very low strain rates as observed in the field. Creep processes until the creep strain rate becomes

as small as about 10

-10

%/sec can be observed by this method. This new method is much less time-consuming than sustained loading

tests starting from the primary loading.

RÉSUMÉ : Des essais oedométriques avec fluages ont été réalisés sur deux types d’argiles remaniées. Pour certains essais, des

fluages ont ete appliqués lors de grands cycles de chargement comprenant de multiples charges/décharges. Les déformations de fluage

observées sont fonction uniquement du rapport entre l’ état de contrainte actuel appliqué et l’ état de contrainte appliqué lors de la

dernière inversion de chargement. Elles restent ainsi indépendantes de l’histoire précédant la dernière inversion et de la seule valeur

de la contrainte actuelle. Une nouvelle procédure expérimentale est ainsi proposée pour étudier de manière plus précise les

déformations de fluage, jusqu'à des valeurs extrêmement faibles (10

-10

%/sec) telles que mesurées in situ. La procédure proposée a

l’avantage d’écourter grandement la durée du chargement comparativement à des essais classiques de fluage réalisés lors d’une

première charge.

KEYWORDS: Clay, One-dimensional compression test, Creep, Strain rate, Loading/unloading/reloading.

1 INTRODUCTION

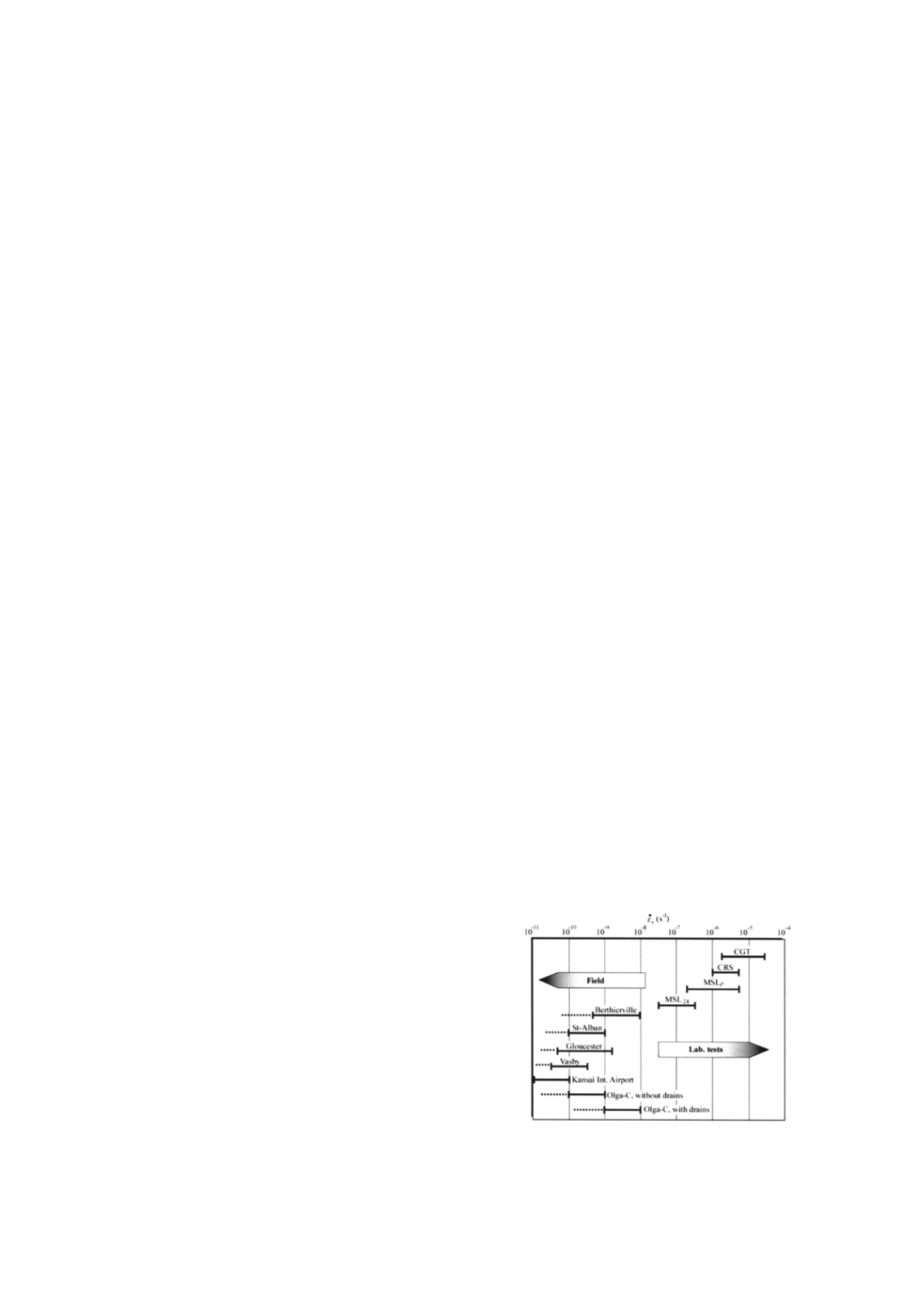

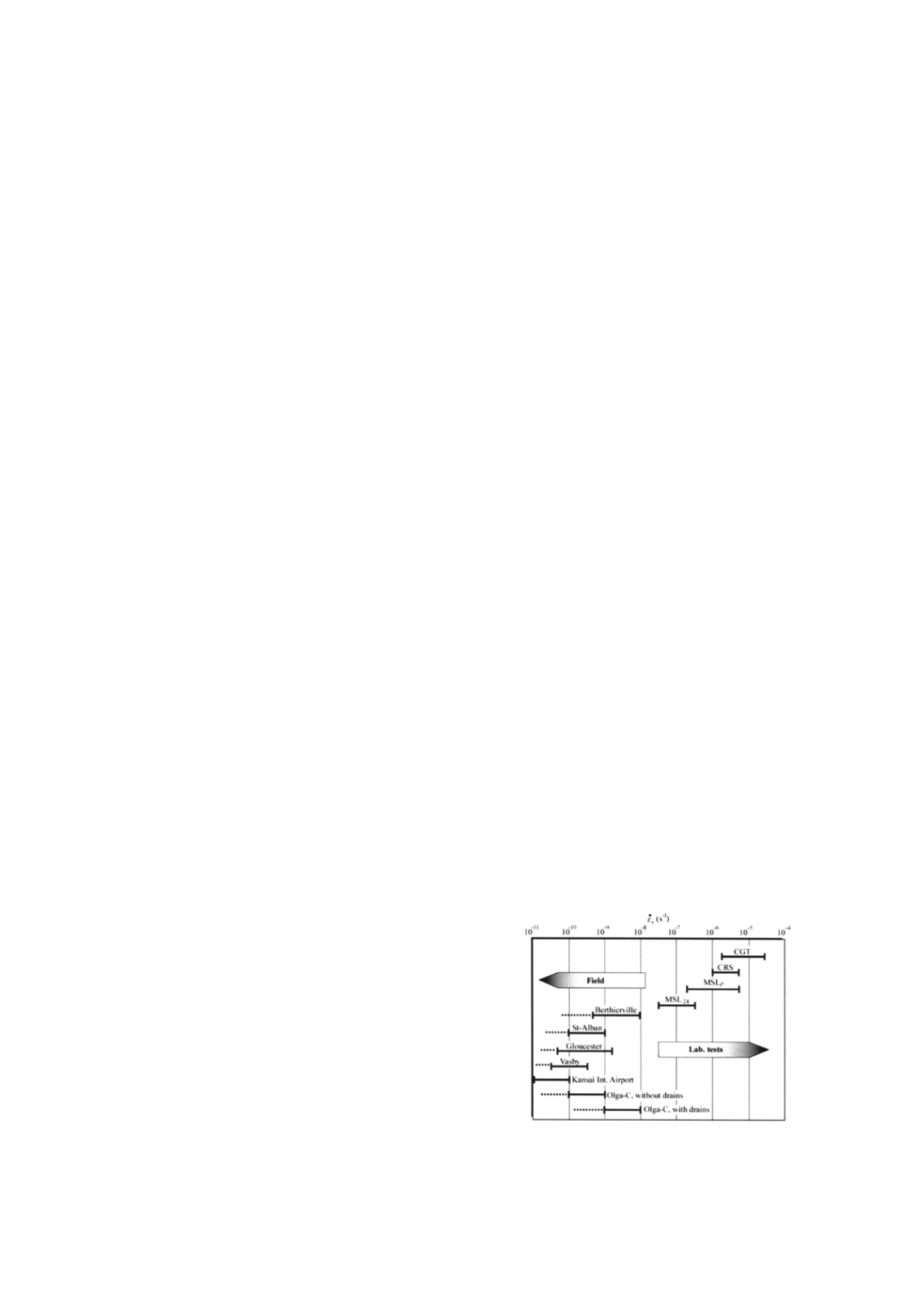

Most of the previous studies on long-term residual compression

of soft clay were focused on the behaviour during primary

loading under the normally consolidated conditions. Despite

strong geotechnical engineering needs, the study under general

loading conditions, not only primary loading but also unloading

(UL), reloading (RL) and cyclic loading (UL/RL), is very

limited (e.g., Acosta Martínez et al. 2005; Kawabe et al., 2009).

Besides, the concerned elapsed time under constant load after

the end of construction in a full-scale soft clay deposit is usually

very long. Therefore, the residual strain rates are very low,

significantly lower than those in ordinary laboratory tests

(Figure 1). Consequently, the field residual deformation can be

predicted from ordinary laboratory test results only when based

on a relevant theoretical framework that can simulate the creep

behaviour at very low strain rates as in the field. However,

laboratory tests to validate such a frameworks as above take

extremely long time when sustained loading is performed until

the strain rate reaches typical values in the field or when

constant-rate-of-strain (CRS) tests are performed at typical

strain rates in the field (Tanaka, 2005).

In view of the above, Kawabe et al. (2011) performed a

series of one-dimensional (1D) compression tests including

multiple unloading/reloading (UL/RL) cycles with many

sustained loading (SL) stages on disc-shaped specimen (

60

mm ×

h

20 mm, Figure 2) made by trimming a large clay cake.

The inside face of the ring was smeared with a grease layer to

decrease the friction. Although the apparatus was relatively

simple, CRS tests could be conducted by means of a feed-back

and automated pneumatic loading system. Figure 3 summarises

the relationships between the creep strain during sustained

loading (SL) for three hours and the ratio of the stress at the

start of unloading (UL) or reloading (RL) at an axial strain rate

equal to ± 0.005 %/min,

UL

or

RL

, to the stress at SL,

SL

.

The creep strain rates during otherwise UR and RL are smaller

than those during otherwise primary loading and become very

small or even negative depending on loading history. Besides,

positive and negative creep strains are a unique function of,

respectively, the loading stress ratio,

SL UL

/

(i.e., over-

consolidation ratio,

OCR

) and

SL

RL

/

, not by the stress

difference,

SL

UL

and

SL

RL

. This relation is also a

function of other factors. For example, the creep strain increases

with an increase in the initial strain rate (i.e., the strain rate

during the CRS loading immediately before the concerned SL

stage) and the elapsed time during the SL stage.

In this study, to confirm the generality of the empirical

relations described in Figure 1, another series of 1D

compression tests including multiple UL/RL cycles with many

SL stages were performed. Based on the test results, a new test

method to observe creep behaviours at very low strain rates in a

relatively short time is proposed.

Figure 1. The strain rate measured in laboratory and in situ (Leroueil

2006)

1