244

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

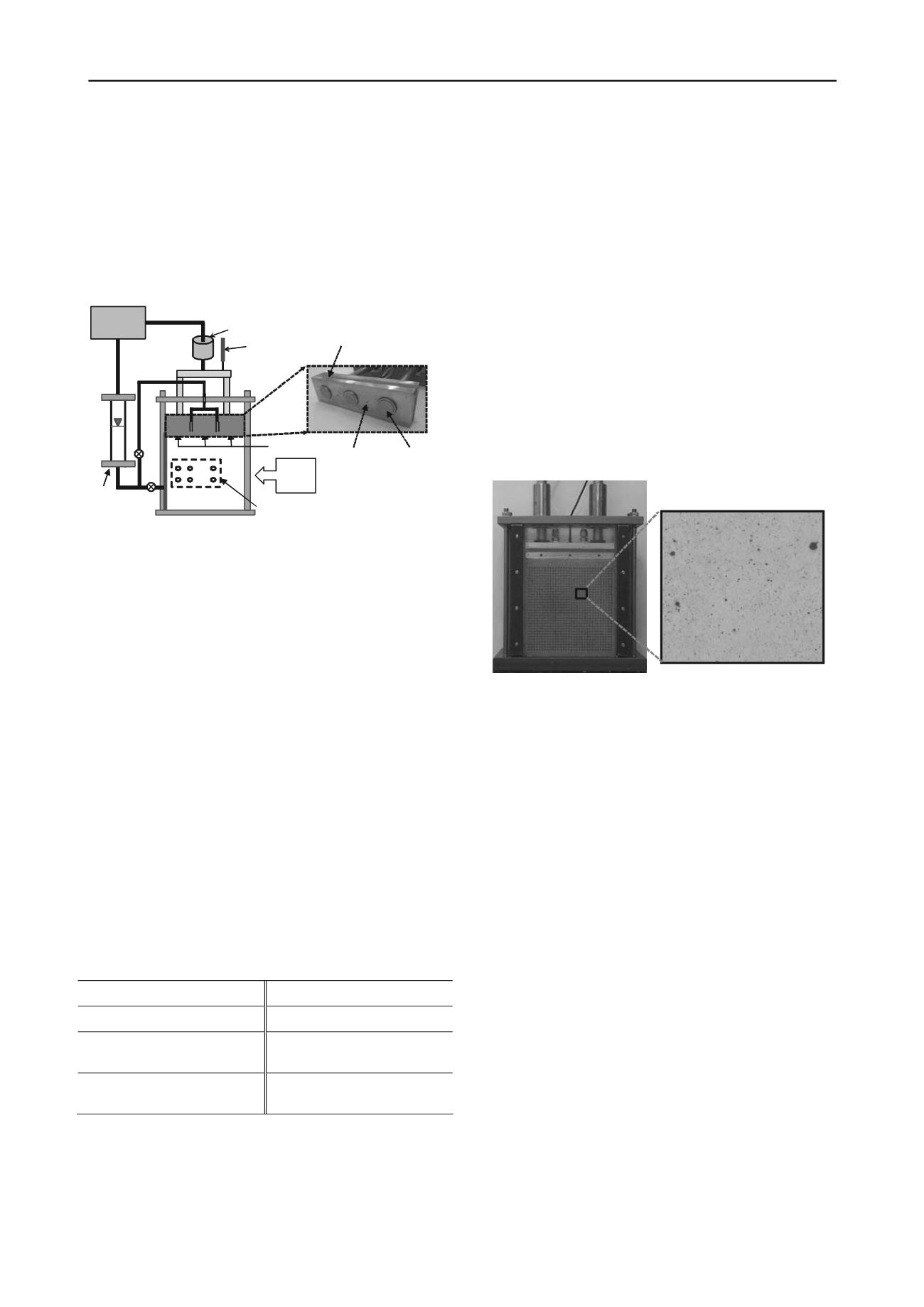

different vertical locations and 3 different horizontal locations

are installed to obtain the pore pressure distributions from the

drain boundary. And 3 earth pressure gauges are mounted on

the top rigid loading platen, which will provide the total vertical

stress variations. A plate of porous plastics used for drain

materials are placed on the top of the specimen for vertical

drainage and at the side for horizontal drainage. The pressure

lines were connected to top and side of model box, which allow

saturation of the sample by applying back pressure and dissipate

pore water.

Figure 1. Schematic diagram of developed consolidation test apparatus

Although the axi-symmetric condition with vertical drains is

in reality, the developed model box simulates plane strain

condition to provide a more favorable environment to perform

digital image analysis. So, if necessary, further study for

modification of the interpretations of the results will be

followed.

2.2. Soils

The reconstituted EPK Kaolinite was used for the test

specimen. Its index properties are summarized in Table 1. The

clay specimens were created using the slurry consolidation

techniques described by Sheeran and Krizek (1971). Dried EPK

Kaolinite powder was mixed with de-aired water until the water

contents reach twice of the liquid limit of the Kaolinite. The

prepared slurry was poured into a large consolidometer of

which diameter is 0.3 m. The slurry was loaded with 10 kPa

increments until the applied vertical pressure reaches 100 kPa.

After reaching the target pressure, the vertical stress was kept

constant for 7 to 10 days for the complete consolidation. After

removing the vertical pressure, the sample was extruded

carefully from the consolidometer, wrapped in plastic films,

coated with paraffin wax, and stored in the controlled humidity

and temperature storage room until ready for use. The

maximum past pressures of the clay samples are determined as

about 100 kPa, from the oedometer test results.

Table 1. Index properties of reconstituted kaolinite

Liquid limit (%)

64.4

USCS

MH

Plasticity index (%)

21.8

Initial void ratio

1.56

Percent finer than #200

sieve (%)

98

Initial water contents

(%)

61.0

Specific gravity

2.55 Maximum past pressure

(kPa)

100

2.3. Test procedure

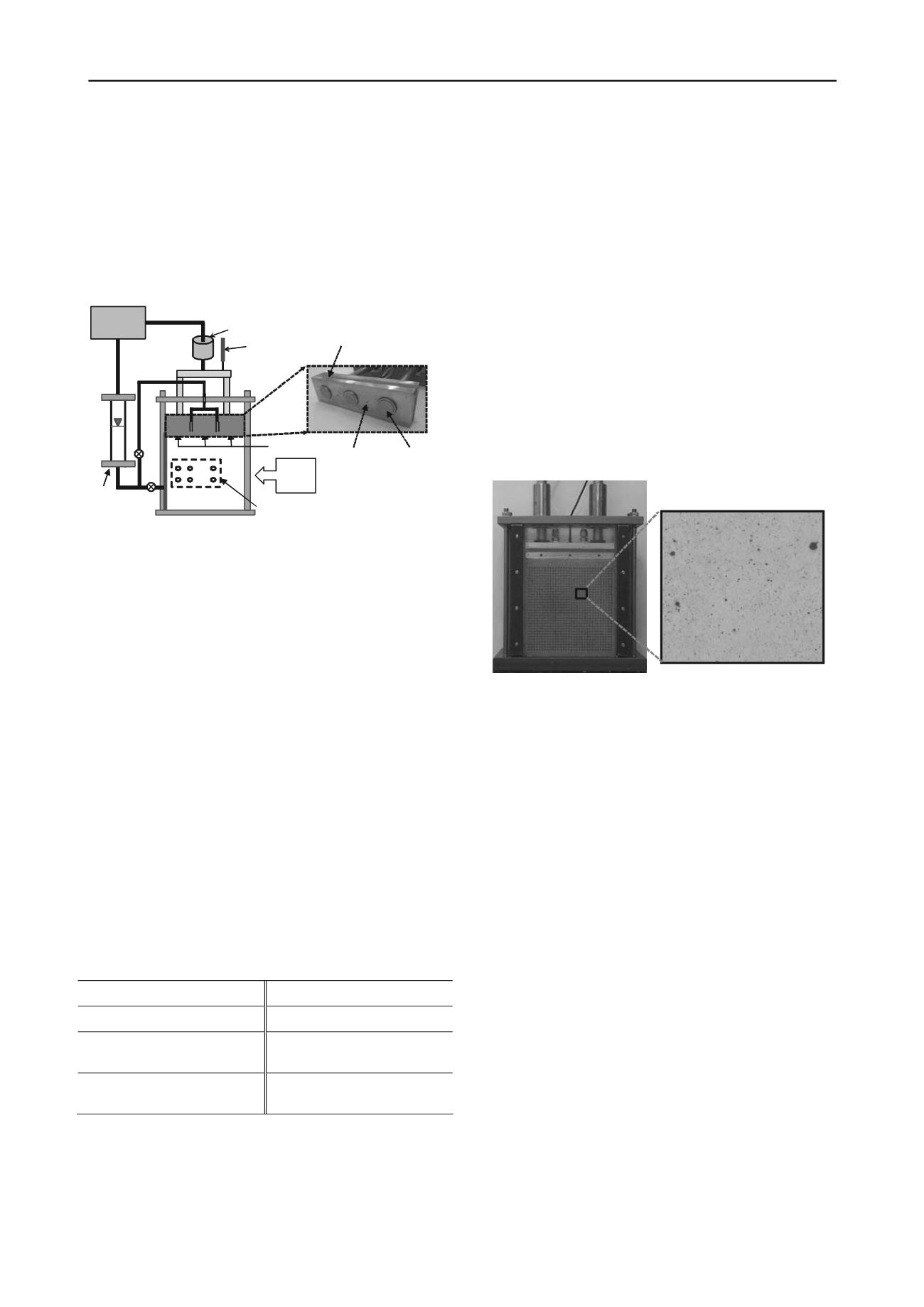

The test procedure with the developed device for consolidation

was summarized as; 1) trimming the reconstituted kaolinite

sample, 2) creating image patterns on the surface of trimmed

sample and 3) assembling test apparatus. Deformation analysis

through image processing is basically done by using two

different images taken at two separate times. For this process, a

random image pattern was created by spraying oil-based paint

on one side of specimen as shown in Figure 2.

After assembling the apparatus with specimen, back pressure

was applied for specimen saturation. Pore pressure parameter C

value defined as the ratio of excess pore pressure increment to

applied vertical total stress, higher than 0.97 was considered as

full saturation. For the consolidation test, vertical stress

increments by pneumatic pressure were applied on the top of

the specimen. Consolidation process was achieved by applying

vertical stress increment under undrained condition and then

opening drainage line. 3 total stress increments (initial stress to

100 kPa, 100 kPa to 200 kPa, and 200 kPa to 300 kPa) were

applied for both tests on horizontal drainage and vertical

drainage condition. Initiating consolidation by opening the

drainage valve, the values of pore water pressure and total

vertical stress are stored via the data logger, and images are

taken at regular time intervals, 10 seconds in the early stage of

consolidation and increasing time steps as consolidation

proceeds. A Nikon D90 digital camera, which has a resolution

of 4288 x 2848 pixels, was used to get photo images.

Earth pressure

gauge

Pore pressure

measuring points

Back pressure

reservoir

LVDT

Digital

Camera

Pneumatic Actuator

Compressor

Silicon

Earth pressure

gauge

1 3 5

2 4 6

Drainage

hole

Figure 2. Prepared sample in the assembled test apparatus

The completion of consolidation was confirmed by both

measuring pore pressure and interpreting time-settlement curve.

After completion of all consolidation tests, water contents at 25

locations for both tests of drained direction were measured. In

this study, to exclude the effect of stress history, final loading

step (200 kPa to 300 kPa of vertical stress increment) was

focused to be analyzed.

2.4. Digital image analysis

In the geotechnical application of the digital image analysis,

two major techniques have been widely used; digital image

correlation (Rechenmacher and Finno 2004) and particle image

velocimetry (White et al. 2003). Herein, the Particle Image

Velocimetry (PIV) technique was employed for the deformation

measurement because of its better performance in convergence

as well as the simplicity of the algorithm. To perform the image

analysis, a flat object is supposed to deform 2-dimensionally in

the plane of the image which can easily be satisfied in the

developed consolidation apparatus which describes plane strain

condition.

Kim et al. (2011) suggested a procedure determining

optimum image processing condition by statistically analyzing

the data of image analysis resulted from the original image of

test specimen and manipulated one. Following this procedure,

the lowest maximum error, which contains the value of

accuracy and precision (Taylor 1999), of approximately 0.002

mm in 90% confidence level was obtained when using PIV with

bi-square interpolation, 60 x 60 pixel subset size and 0.28 % of

vertical strain interval. As shown in Figure 2, the adopted image

in the test specimen is divided into 1024 (32×32) pixel subsets;

thus, providing 1024 displacement vectors at the center points

of the pixel subsets.