242

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figure 5 shows that for both pumice sands there is

considerable particle breakage during the drained shearing and

that this is progressively more severe as the confining pressure

increases. Note that the Japanese pumice is much finer than the

New Zealand material but the general features of particle

crushing are similar for both materials. One interesting

observation for the NZ material is that there is much less

particle crushing for the undrained test following consolidation

to 1600 kPa than for the drained test from the same

consolidation pressure. The reason is because of the differing

stress paths. For the drained test the stress paths for drained

compression, if plotted on the set of axes in Figure 4, is a line of

slope +3 upwards and towards the right. On the other hand since

the specimens are loose the undrained effective stress path will

move to the left and so subject the sand particles to lower

effective stresses.

Figure 6 presents a surprising insight into the deformation

behaviour of these materials. In the drained triaxial test the axial

deformation and the volume change are measured. From this it

is possible, with the usual assumption that the specimen

deforms as a right circular cylinder, to determine the change in

diameter of the specimen. The figure shows that for higher

consolidation pressures there is zero or very little change in

diameter of the specimen. In fact, for the New Zealand pumice

for consolidation pressures of 400 and 1600 kPa it is seen that

the diameter of the specimen actually decreases, that is there is a

decrease in length because of the compression and also lateral

compression. In our view this is a consequence of the large

amount of particle crushing at these higher consolidation

pressures. This observation was first made in the paper by

Pender at al (2006) on the properties of New Zealand pumice

sands.

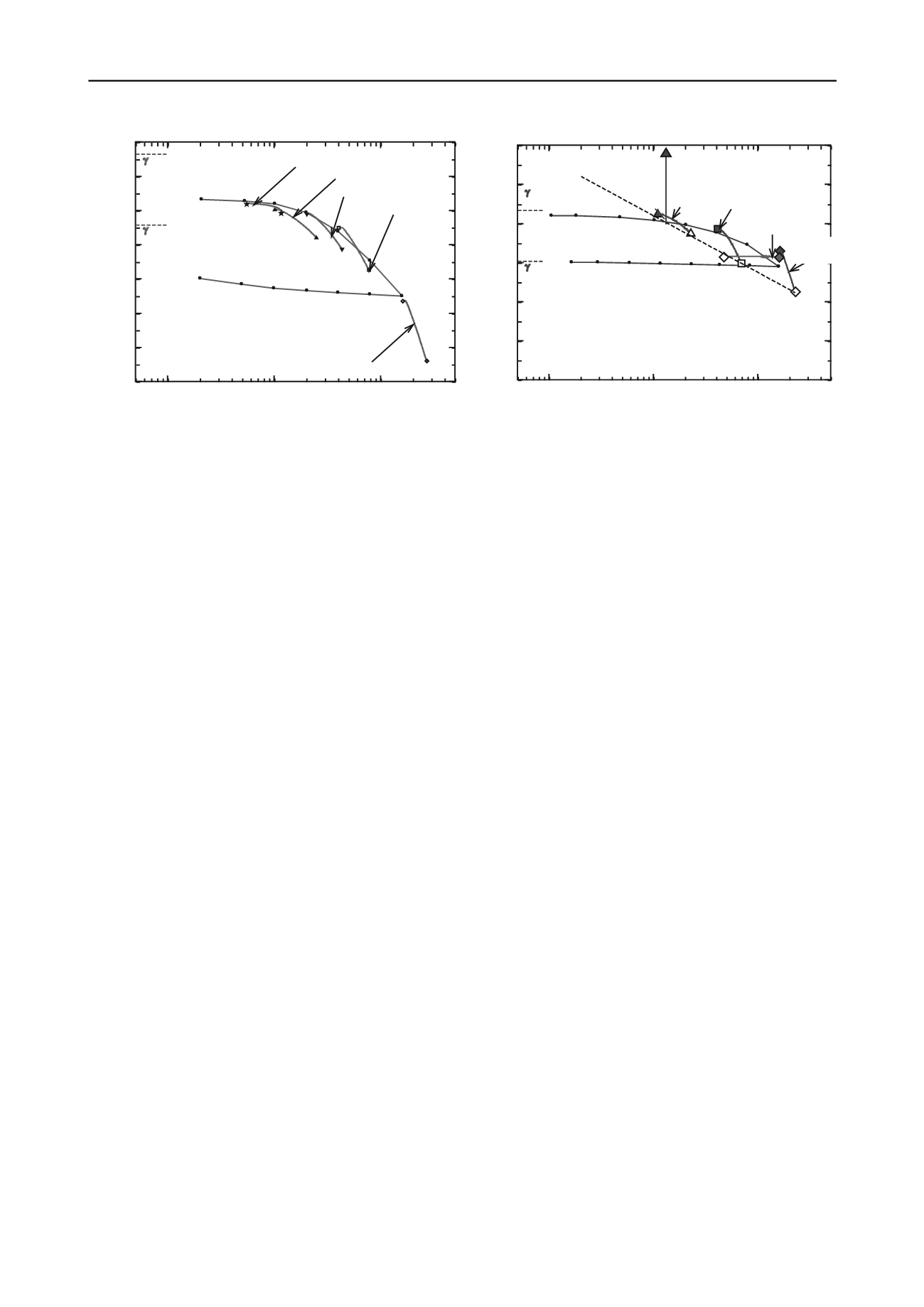

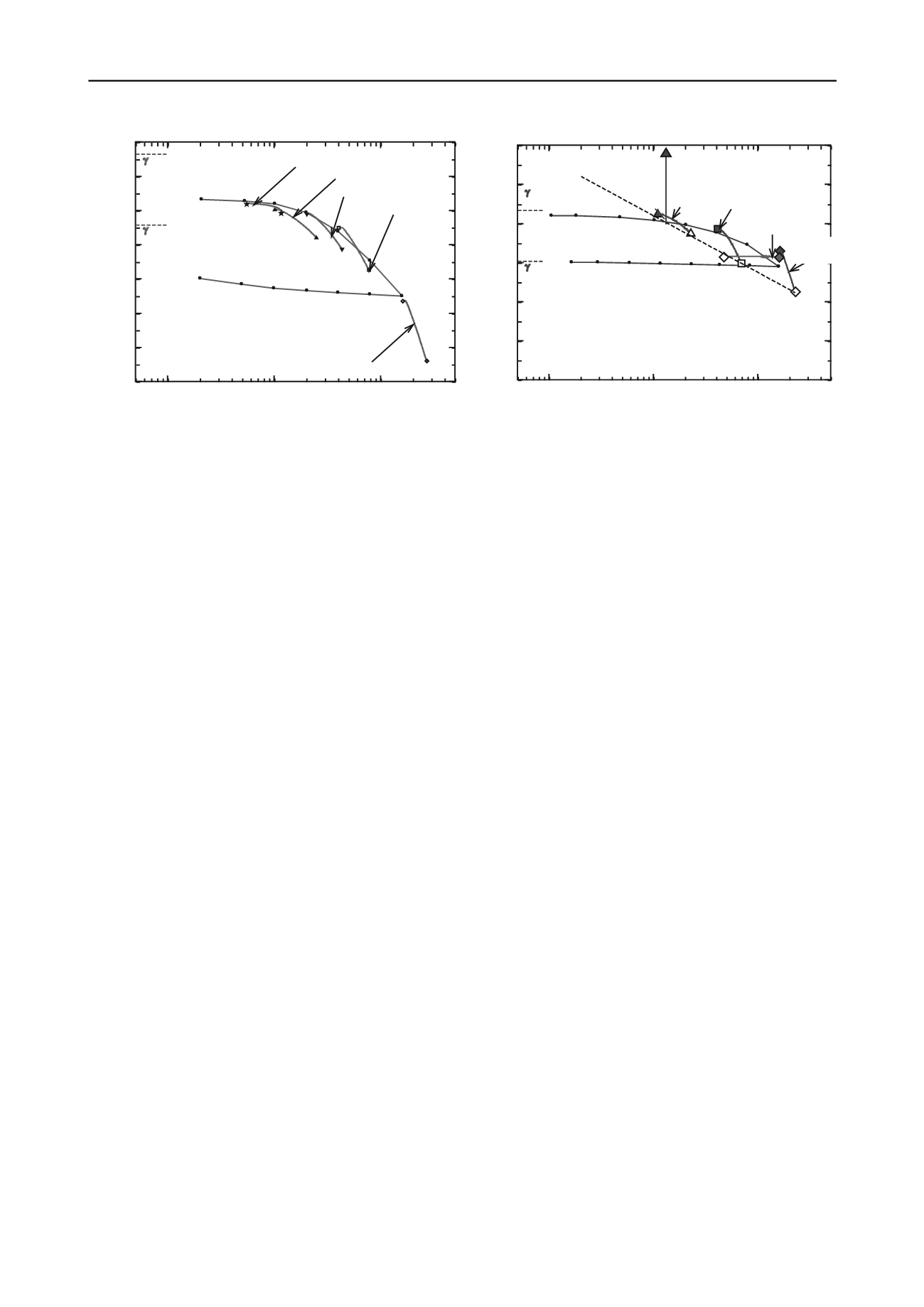

Figure 7 plots the dry unit weight of the specimens tested on

the vertical axis against the logarithm of the mean principal

effective stress on the horizontal axis. In the Critical State

literature diagrams such as this are plotted with the void ratio on

the vertical axis. However, one of the difficulties of dealing

with material having voids within the particles is that the value

for the “operational”

solid density is unclear. So in Table 1 the

values given for the solid density are reasonable indications but

not exact values. One way to overcome this difficulty is to use

the dry unit weight rather than the void ratio, hence the vertical

axes in Figure 7. The beginning and end points of the various

shear tests are shown in Figure 7 along with the hydrostatic

compression curves. For the New Zealand pumice results in

Figure 7b a dotted straight line is drawn through the end points.

However, this cannot be regarded as a critical state line as

Figures 2 and 3 show that the state of the specimens has not

reached a condition with constant q and constant volume.

3 CONCLUSIONS

The main conclusions derived from this brief comparison of the

properties of New Zealand and Japanese pumice sands are:

The properties of the materials are very similar, despite

their different origins and particle size distributions.

In drained triaxial testing, neither the shear stress or the

specimen volume reaches a steady value even at axial

strains of 20% (Figs. 2 & 3).

During drained shearing particle crushing is

considerable (Fig. 5).

There is no well-defined angle of shear resistance (Fig.

4).

At high confining pressures the lateral deformation

during drained shear indicates behaviour close to one-

dimensional compression (Fig. 6).

Figure 7 indicates that the materials have not reached a

critical state condition.

4 ACKNOWLEDGEMENTS

We are very grateful to the Japan Society for the Promotion of

Science (JSPS) for support. This research has been partially

funded by a JSPS Grant-in-Aid for Young Scientists (B)

(No.23760448).

5 REFERENCES

Kikkawa, N., Orense, R.P. & Pender, M.J. (2011). ”Mechanical

behaviour of loose and heavily compacted pumice sand,”

Proc.,

14

th

Asian Regional Conference on Soil Mechanics and

Geotechnical Engineering

, Hong Kong, 23-27 May 2011, Paper

214. 6pp.

Pender, M J, Wesley, L D, Larkin, T J and Pranjoto, S (2006)

“Geotechnical properties of a pumice sand.” Soils and

Foundations, Vol. 46, No. 1, pp. 69-81.

Wesley, L. D., Meyer, V. M., Pranjoto, S, Pender, M. J., Larkin,

T. J. and Duske, G. C. (1999)

“Engineering properties of

pumice sand” Proc. 8th Australia

-NZ Conference on

Geomechanics, Hobart, Vol. 2, 901-908.

10

1

10

2

10

3

10

9

8

7

6

5

4

Dry unit weight

d

(kN/m

3

)

Mean effec tive princ ipal stress

p

' (kPa)

130kPa

NZ pumice

100kPa

NZ pumice

1600kPa,CU test

NZ pumice

1600kPa

NZ pumice

400kPa

dmin

NZ pumice

dmax

NZ pumice

10

1

10

2

10

3

11

10

9

8

7

6

5

4

Dry unit weight

d

(kN/m

3

)

Mean effec tive princ ipal stress

p

' (kN/m

2

)

JPN pumice,50kPa

JPN pumice,100kPa

JPN pumice,200kPa

JPN pumice,400kPa

JPN pumice,1600kPa

dmax

JPN pumice

dmin

JPN pumice

(a) JPN pumice

(b) NZ pumice

Figure 7. Paths of dry unit weight against mean principal effective stress for the hydrostatic compression and drained triaxial tests.