237

Technical Committee 101 - Session I /

Comité technique 101 - Session I

stage, plotted in the same way as Figure 3. Also in this case, the

relation is independent of loading history and stress at SL stage,

and the relations for the two tests are nearly the same. This

result indicates that the empirical rule presented in Figure 3 is

also valid for a wide variety of loading history, at least when the

void ratio range is as small as in these tests.

The current creep strain rate is controlled by the

instantaneous yield characteristics. As typically seen from

Figures 4a and 5, the stress at which large-scale yielding starts

is not a fixed value but controlled by loading history. Kawabe et

al. (2011) showed that the hysteretic stress-irreversible strain

relations during cyclic one-dimensional compression of clay can

be adequately described by revising the proportional rule that

was originally proposed for shear tests (Tatsuoka et al. 2003).

This feature is referred to below when inferring very low creep

strain rates during otherwise cyclic loading.

3.2 Very low creep strain rates

Many clay types exhibit the Isotach viscous properties in one-

dimensional compression (e.g., Imai 1995; Niemunis and Krieg

1996; Leroueil et al.1996; Leroueil and Marques 1996: Kawabe

et al. 2011). In that case, at the ‘

loading

‘ state in the sense that

the irreversible axial strain rate,

, has been kept positive

since the start of loading, a unique effective stress is defined for

given irreversible strain and its rate. Then, the

a

a

ir

a

log

curve of a CRS test at a lower

value is located more left or

lower in the plot presented in Figure 7. The

value at the

strain-stress state,

ir

a

ir

a

) , (

a a

, that is ultimately reached in any SL

is zero. These zero-strain-rate states form the stress-strain

relation called the reference relation. The reference relation is

the same for different loading histories keeping the same sign of

, but different for different loading histories changing the

sign of

. In Figure 7, the reference relation at the ‘

loading

’

state and the one for the ‘

first unloading

‘ state, where

has

become negative for the first time since the start of loading, are

presented. Point B is located on the first unloading curve

starting from point A (on the primary loading curve). During

this unloading process, the total axial strain rate,

a

ir

a

ir

a

ir

a

(= + )

is negative, but

is kept positive while the elastic axial strain

rate

is kept negative with a negative axial stress rate. Note

again that all the strain-stress states located right of, or above,

the reference relation for ‘loading‘, including points A, B and

B’, are at the ‘loading‘ state.

e

a

ir

a

ir

a

e

a

0

Faster

Measured

�

‐log

�

relation

No creep

or : positive or negative creep

�

log

�

Reference relation for ‘

loading

’

Reference relation for

‘

first unloading

’

Primary loading at a constant

positive total strain rate

First unloading at a

constantnegative

total strain rate

0

ir

a

B

A

C

B’

C’

Figure 7 Illustration of

a

a

log

and creep in Isotach theory

In SL at the ‘

loading

’ state (where

> 0), as the initial

strain rate at the start of SL becomes lower, the reference

relation is reached faster while the residual creep strain rate

after the same elapsed time since the start of SL becomes

smaller. For example, the reference relation is reached much

faster when SL starts from point B than when SL starts from

point A. By taking advantage of this feature, in a relatively short

period by starting after having made some unloading (such as

point A to point B), we can reach the creep behaviour at very

low strain rates that can be observed only after a very long

period when SL starts during otherwise primary loading.

ir

a

Figure 8a shows the

a

a

log

relation from a CRS test on

kaolin clay, in which CRS primary loading was followed by: 1)

a SL stage, SL1; 2) a small unloading; 3) another SL stage,

SL2; and 4) a global RL another SL stage, SL4. Figure 8b is the

zoom-up of the behaviours around the stages 1) – 3). Despite

that the viscous properties of Fujinomori clay is slightly non-

Isotach (Kawabe et al. 2009), the result from a similar test

performed as the above (test FJM1104, cf. Figure 10) was

analysed below in the framework of Isotach viscous properties.

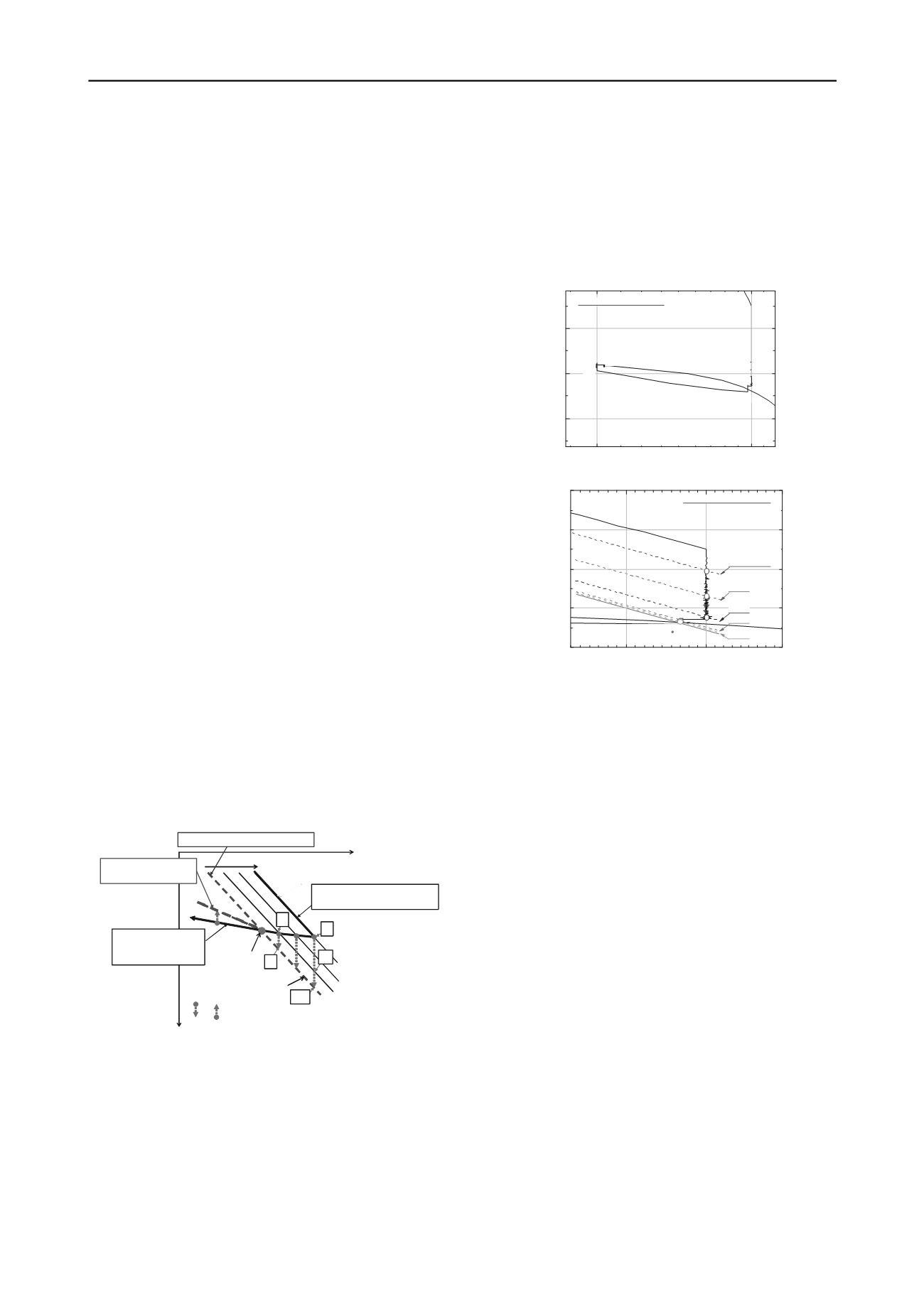

a)

300

600

9.5

9.0

8.5

SL4

SL3

SL2

Test Name: KLN1101

Axial strain,

a

(%)

Axial stress,

a

(kPa)

SL1

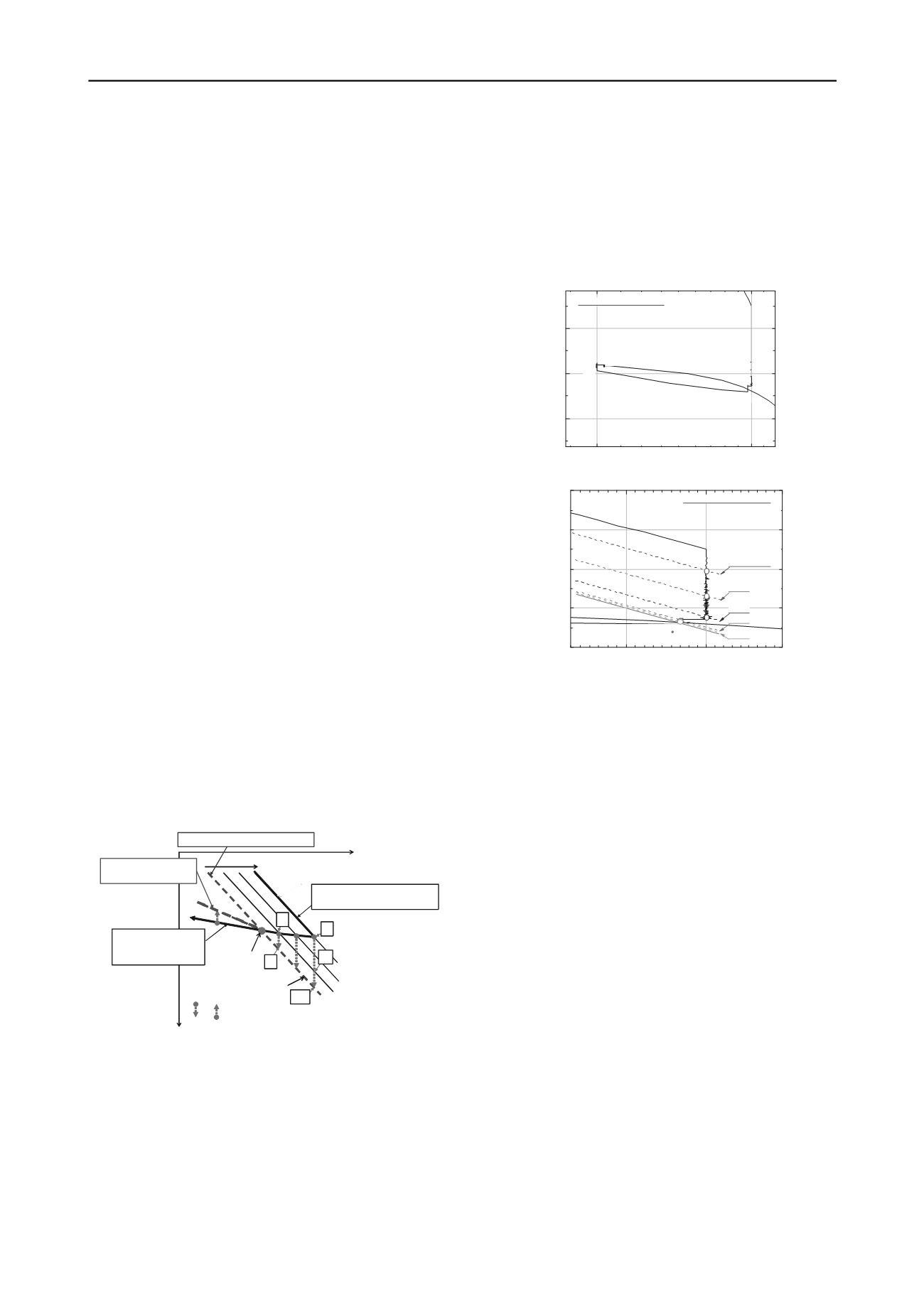

b)

570

600

630

9.5

9.0

8.5

8.0

7.5

1E-9

1E-8

1E-7

1E-6

1E-5 %/sec

Axial strain,

a

(kPa)

Axial stress,

a

(kPa)

Test Name: KLN1101

a(creep)

=0

Figure 8. a) Zoom-upped

a

a

log

relation; and b) behaviours

around SL1 and SL2 stages, test KLN1101

Figures 9a and 10a show the

Δt

log

log

a(creep)

relations

from tests KLN1101 and FJM1104, where SL1 starts during

otherwise the primary loading and SL2 starts during otherwise

the first unloading following SL1 (see Figure 8a). It may be

seen that the creep strain rate,

a(creep)

Δ

Δt

, decreases linearly

with the logarithm of the elapsed time,

, since the start of SL

at both SL1 stages. The relations at SL1 and SL2 are different,

showing that the elapsed time since the start of respective SL

stages,

is not the parameter that controls the creep

behaviours at different stresses,

SL

Δt

. Figures 9b and 10b show

the

a(creep)

a(creep)

log

log

Δ

relations from these two tests.

The two relations at SL1 are nearly straight until

a(creep)

becomes about 10

-7

%/sec. The relations at SL2 stage are utterly

different from the above.

Referring to Figure 7, according to the Isotach theory, the

creep behaviour from point B to point C is equivalent to the one

from point B’ to point C’ at the last part of the SL that has

started from point A at the primary loading state. The

value

is the same at points B and B’ and at points C and C’.

Correspondingly, in Figure 8b, the

a

a

ir

a

log

relations for

different

values that are in parallel to each other have been

depicted (i.e., broken lines). Each of these relations passes

different

a a

ir

a

(

) ,

states where different strain rate was

observed. Following this procedure, in Figures 9b and 10b, the

measured relations of SL2 have been parallel-shifted upwards to

be connected to the end part of the relation of the respective

SL1 stages. The combined relations can be regarded as the

continuous relations that would have been obtained if SL1 had

continued longer than the actual tests.

The obtained relations exhibit a drastic decrease in the slope

toward eventually zero

a(creep)

. This trend is consistent with