236

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

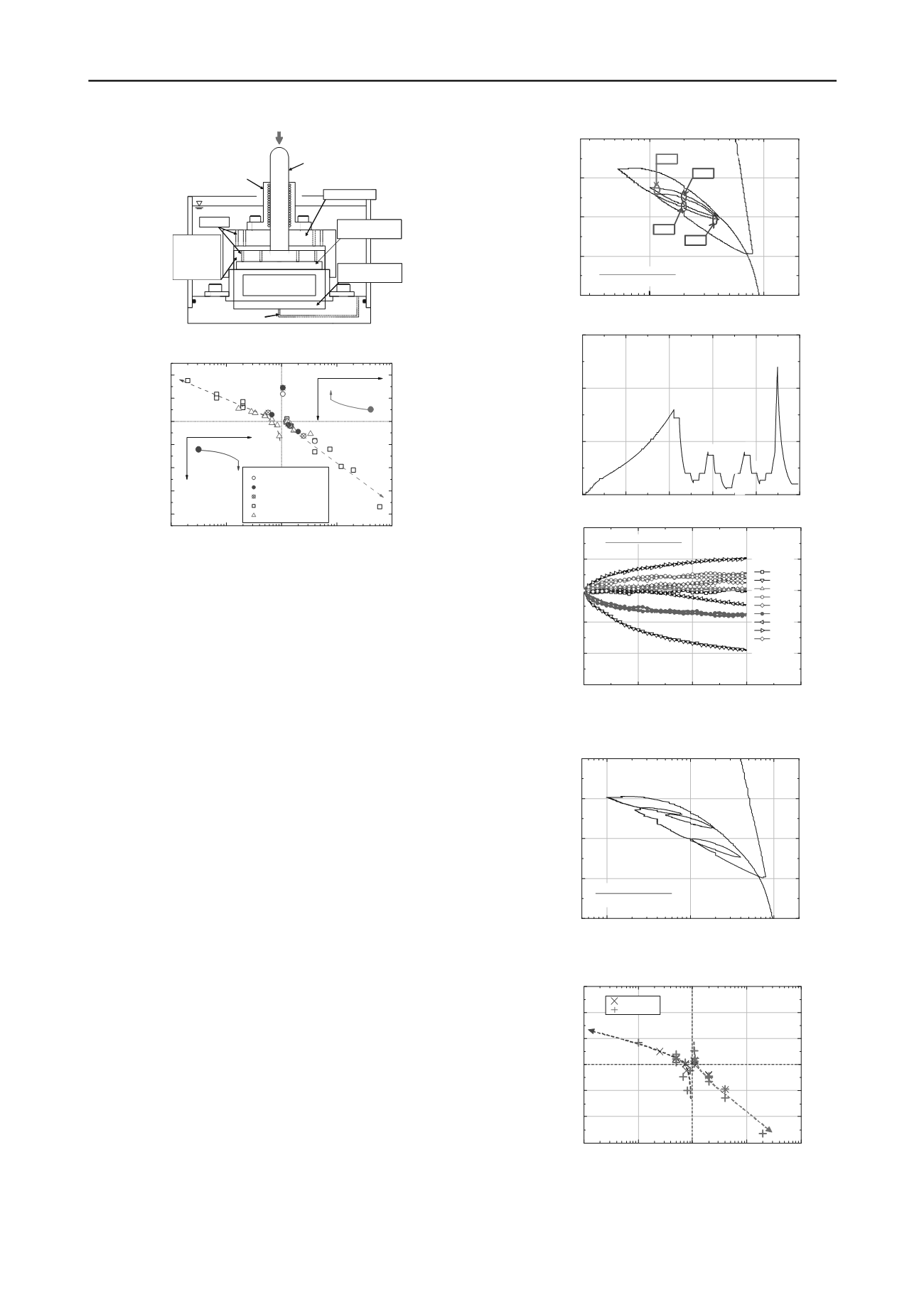

供試体

φ 60× 20 mm

ポーラスストーン(φ

60× 5 mm)

ポーラスストーン(φ 56× 5 mm)

Loading piston

(one unit with

the specimen cap)

Vertical load

Ball bearing bushing

Specimen

(60 mm d x 20 m h)

Drainage line

Porous stone disc

(56 mm d x 5 mm h)

Drainage

Specimencap

(free vertical

movement,

guided against

rotation)

Porous stonedisc

(60 mm d x5 mm h)

Loading capsule

Figure 2. Oedometer used in the present study (Kongkitkul et al. 2011)

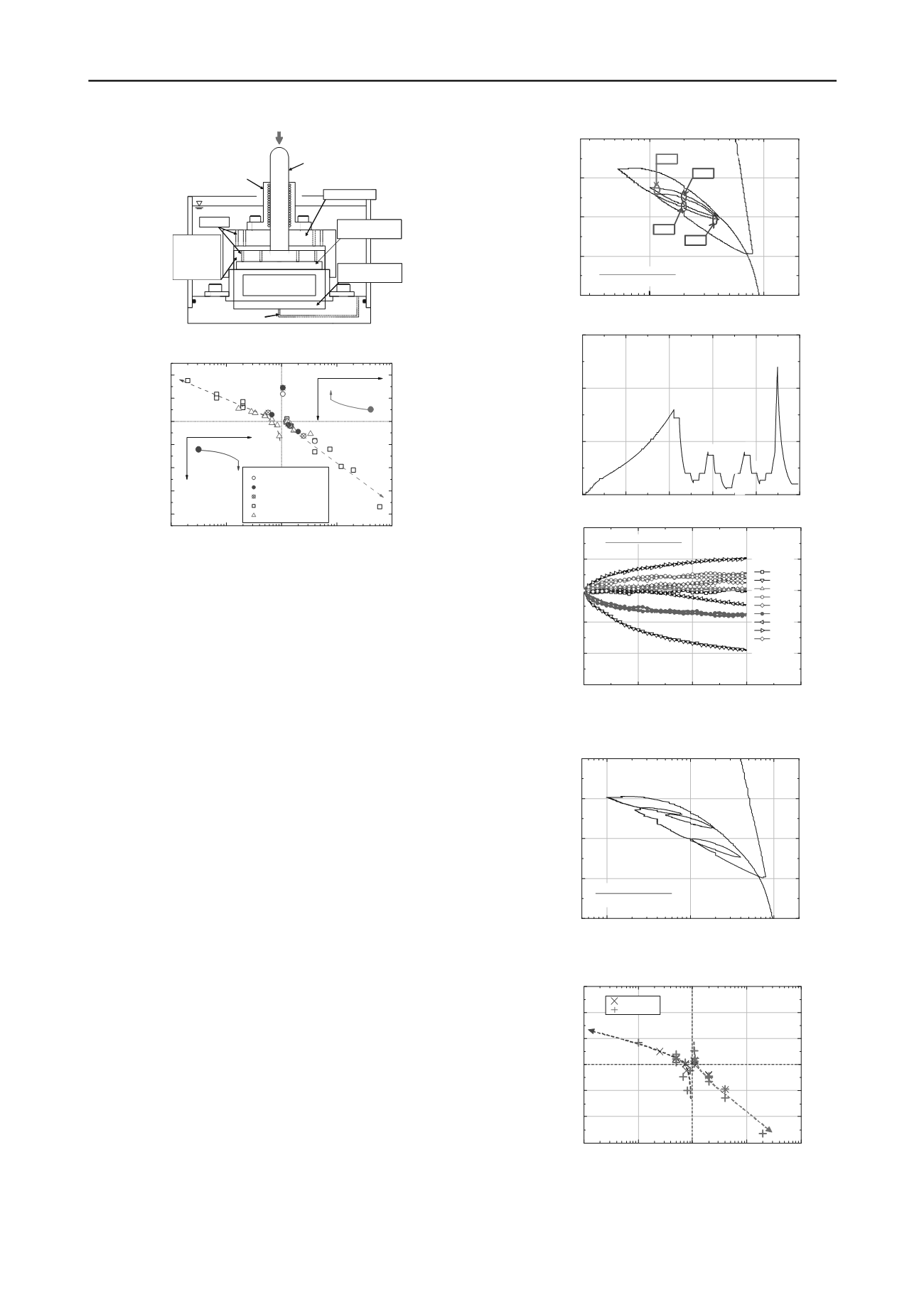

0.01

0.1

1

10

100

-0.4

-0.3

-0.2

-0.1

0.0

0.1

0.2

a(creep)

-

RL

/

SL

a(creep)

-

UL

/

SL

SL

UL

a(creep)

(%)

UL

/

SL

or

RL

/

SL

TEST 1 (Loop1)

TEST 1 (Loop2)

TEST 1 (Loop3)

TEST 2

TEST 3

log

a

a

SL

RL

log

a

a

Figure 3. Relationship between the creep strain and loading stress level

(Kawabe et al. 2011)

2 ONE-DIMENSIONAL COMPRESSION TESTS

The test method is basically the same as Kawabe et al. (2011).

Large clay cakes of two types of reconstituted soft clay,

Fujinomori clay (

L

≈ 42 % and PI ≈ 15) and kaolin clay

(

L

≈ 44 % and PI ≈ 16), were produced by consolidating

slurry prepared at a water content twice of the liquid limit at

=

100 kPa in a 20 cm diameter cylinder for a week. After having

applied a pre-load scheme to minimize effects of disturbance

during specimen preparation, each specimen, drained at the top

and bottom, was subjected to: monotonic recompression at

a

w

w

= 0.05 %/min to

a

= 100 kPa; SL for one day; UL at

a

= -

0.05 %/min to

a

= 100 kPa; and SL for one day. Logarithmic

axial strains are used throughout this paper. It was ensured that

the specimen under the conditions described above is always

essentially drained from the fact that the excess pore water

pressure measured at the undrained bottom of the specimen with

the drained top set in another apparatus was always less than

1 % of transient applied total axial stress (Kawabe et al. 2011).

So, the measured total axial stress,

a

, is regarded as the

effective axial stress.

3 TEST RESULTS

3.1 Creep during multiple unloading/reloading cycles

In the test described in Figure 4a (test FJM1008), a number of

SL stages for three hours were applied during multiple CSR

UL/RL cycles changing the stress amplitude. Figures 4b and c

show the time histories of

a

and creep axial strain at each SL

stage,

a(creep)

Δ

/

. In Figure 4c, the data sets for the same value

of

SL UL

or

SL

RL

/

are denoted by the same symbol.

The creep characteristics at similar value of

SL UL

/

or

SL

RL

/

are similar, independent of loading history and axial

stress at SL stage. The similar test result is shown in Figure 5. It

is to be noted that these relations change with changes in the

elapsed time of SL.

a)

100

1000

19

18

17

16

15

Test Name: FJM1008

w

0

= 37.5 %, e

0

= 1.02

Axial strain,

a

(%)

Axial stress,

a

(kPa)

500

④

,

⑫

③

,

⑪

⑤

,

⑨

⑥

,

⑩

b)

0

24

48

72

96

1

0

500

1000

1500

20

⑫

⑪

⑩

⑨

⑧

⑦

⑥

⑤

④

③

②

Axial stress,

a

(kPa)

Elapsed time,

t (hour)

①

c)

0

1

2

3

-0.15

-0.10

-0.05

0.00

0.05

0.10

4

Test Name: FJM1008

Creep axial strain,

a(creep)

(%)

Elapsed time,

t (hour)

①

②

③ , ⑪

④ , ⑫

⑤ , ⑨

⑥ , ⑩

⑦

⑧

⑨

Figure 4. a) Zoom-upped

a

a

log

relations; b) stress history; and

c) time history of creep strain, test FJM1008

10

100

1000

18

16

14

12

10

Test Name: FJM1016

w

0

= 41.8 %, e

0

= 1.11

Axial strain,

a

(%)

Axial stress,

a

(kPa)

Figure 5. Zoom-upped

a

a

log

relation. test FJM1016

0.01

0.1

1

10

100

-0.3

-0.2

-0.1

0.0

0.1

0.2

0.3

Creep axial strain,

a(creep)

(%)

UL

/

SL

or

RL

/

SL

FJM1008

FJM1016

Figure 6.

a(creep)

Δ

-

SL UL

/

or

SL

RL

/

relations, tests

FJM1008 and FJM 1016

Figure 6 shows the relationship between

a(creep)

Δ

for three

hours and the stress ratio,

SL UL

/

or

SL

RL

/

, at each SL