238

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

the Isotach theory, by which the

a(creep)

value becomes

ultimately zero in a given SL stage (i.e., points C and C’ in

Figure 7). This trend is seen in the test result presented in Figure

8b. In this figure, the reference relation, along with

a(creep)

= 0,

has been drawn based on the value of

UL S

/(

L

at

a(creep)

Δ

=

0) = 1.25 that was obtained from a similar test result as those

presented in Figure 3 and 6. The axial strain increment,

a

Δ

,

between the relations for the

a

a(creep)

values different by a factor of

10 (i.e., one log. cycle of

) is similar until

a(creep)

becomes about 10

-7

%/sec, after which

a

Δ

becomes smaller

towards zero as the relation approaches the reference line.

The largest advantage of the method proposed above is that

creep behaviours at very low strain rates can be observed in a

relatively short. This method becomes reliable when the

reference relation along

a(creep)

= 0 is obtained from such

relations as shown in Figures 3 and 6 by performing many SL

during otherwise UL and RL. Extending the method described

above, creep behaviours at very low strain rates (positive or

negative) starting during otherwise UL/RL can be predicted by

inferring the hysteresis reference relation.

4 CONCLUSIONS

The following conclusions can be derived:

1) The creep strain during normally or over-consolidated

conditions after arbitrary loading history is controlled by the

ratio of the stress at load reversal immediately before to the

stress at sustained loading, irrespective of loading history

and the stress at sustained loading.

2) With Isotach materials, creep behaviour at very low strain

rates as those reached after a long period by sustained

loading starting during otherwise primary loading can be

observed in a relatively short period by performing

sustained loading after a relevant amount of stress reversal.

3) The logarithm of creep strain rate decreases rather linearly

with creep strain until the creep strain rate becomes a

certain low value, followed a drastic decrease toward zero.

5 REFERENCES

Acosta-Martínez H., Tatsuoka, F., and Li, J.-Z. 2005. Viscousproperty

of clay in 1-D compression: evaluation andmodelling.

Proc. 16

th

ICSMGE, Osaka

, 779-783.

Imai, G. 1995. Analytical examination of the foundations toformulate

consolidation phenomena with inherent timedependence.

Keynote

Lecture, Proc. Int. Symp. on Compressionand Consolidation of

Clayey Soils, IS Hiroshima

. (2) 891-935. Rotterdam: Balkema.

Kawabe, S., Kaihara, K. and Tatsuoka, F. 2009. Non-Isotach viscous

property and its simulation in drained one-dimensional compression

on clay.

Proc. of 44

th

Conf. on Geotechnical Eng., Japan

Geotechnical Society

,

Yokohama

, 237-238. (in Japanese)

Kawabe, S., Kongkitkul, W. & Tatsuoka, F. 2011. 1D Compression

with Unload/Reload Cycles on Soft Clay and its Simulation.

Proc.

14

th

Asian Regional Conference on SMGE, Hong-Kong, CD

.

Kongkitkul, W., Kawabe, S., Tatsuoka, F. and Hirakawa, D. 2011. A

simple pmeumatic loading system controlling stress and strain rates

for one-dimensional compression of clay.

Soils and Foundations

51

(1), 11-30.

Leroueil, S., and Marques, M.E.S. 1996. Importance ofstrain rate and

temperature effects in geotechnical engineering.

S-O-A Report,

Measuring and Modeling TimeDependent Soil Behavior, ASCE

Geotech. Special Publication

. 61, 1-60.

Leroueil, S., Perret, D., and Locat J. 1996. Strain rate andstructuring

effects on the compressibility of a youngclay.

Measuring and

Modeling Time Dependent Soil Behavior,ASCE Geotech. Special

Publication

61, 137-150.

Leroueil, S. 2006. Suklje’s Memorial Lecture – The isotache approach:

Where are we fifty years after its development by Professor Suklje?.

Proc. European-Danube Conference on Geotechnical Engineering,

Ljubljana,

1, 55-88.

Niemunis, A., and Krieg, S. 1996. Viscous behaviour ofsoil under

oedometric conditions.

Canadian GeotechnicalJournal

33, 159-168.

Tanaka, H. 2005. Consolidation behaviour of natural soils around

p

c

value - long term consolidation test -.

Soils and Foundations

, 45(3)

83-95.

Tatsuoka,F., Masuda,T. and Siddiquee,M.S.A. 2003. Modelling the

stress-strain behaviour of sand in cyclic plane strain loading.

Geotechnical and Environmental Engineering, Journal of

Geotechnical and Environmental Engineering, ASCE

, 129 (6) 450-

467.

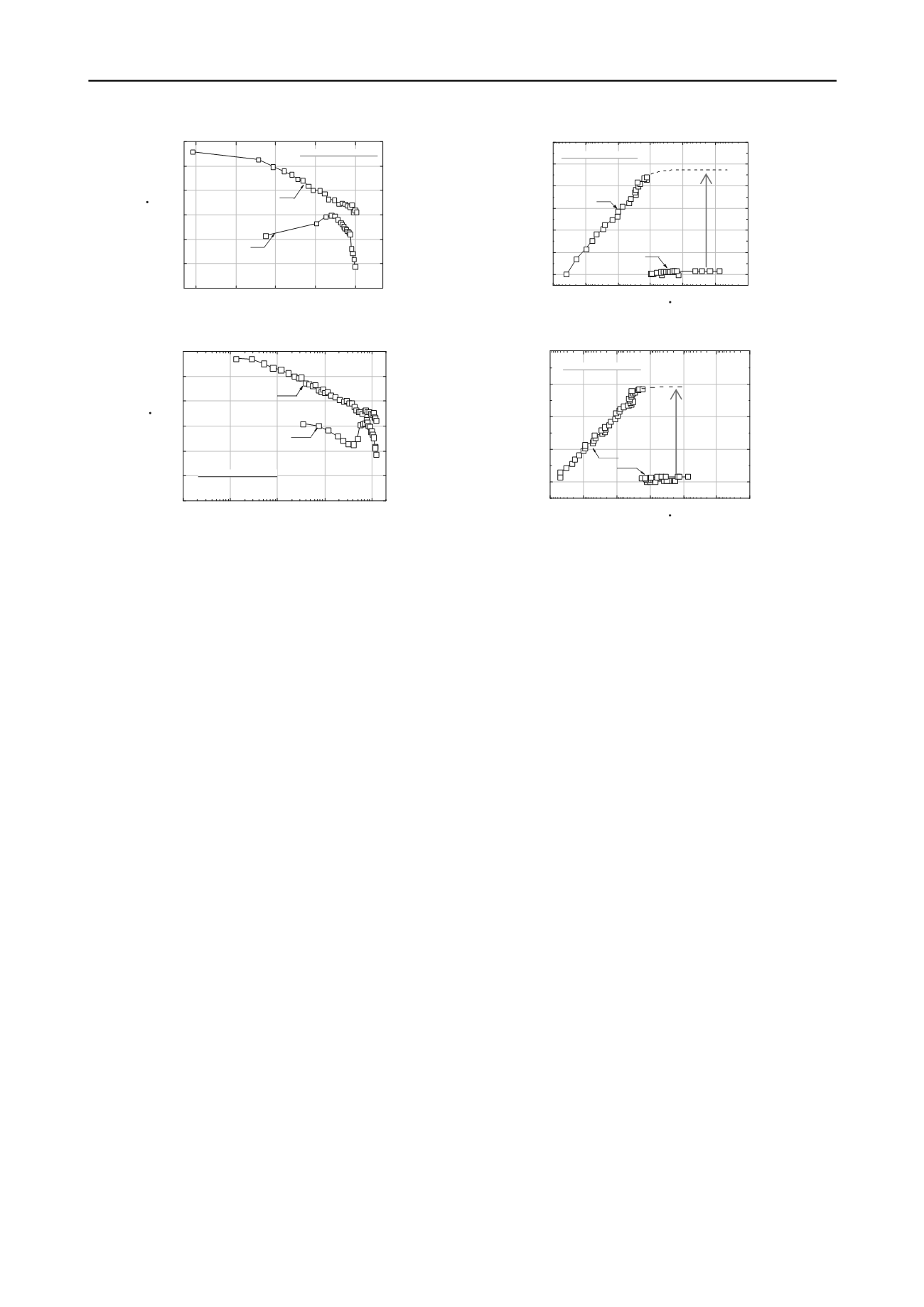

Figure 9. Test KLN1101 (SL1 and SL2): a)

Δt

log

log

a(creep)

relations; and b)

a(creep)

a(creep)

log

Δ

relations

100

1000

10000 100000 1000000

1E-10

1E-9

1E-8

1E-7

1E-6

1E-5

1E-4

TestName:KLN1101

Creep axial strain rate,

a(creep)

(%/sec)

Elapsed time,

t (se

SL1

c)

SL2

1E-4 1E-5 1E-6 1E-7 1E-8 1E-9 1E-10

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Creep axial strain,

a(creep)

(%)

Creep axial strain rate,

TestName:KLN1101

a(creep)

(%/sec)

SL1

SL2

b)

a)

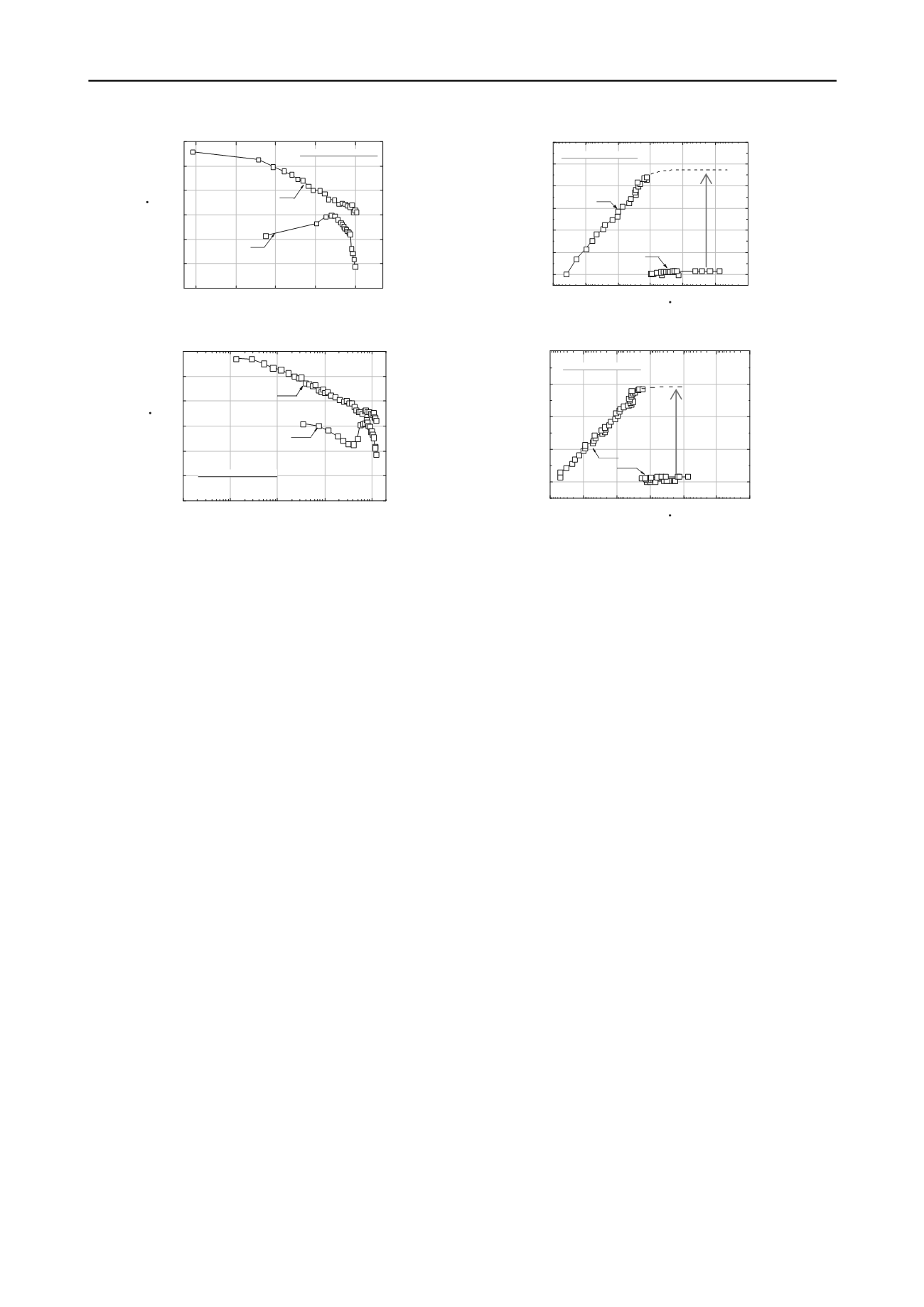

Figure 10. Test FJM1104 (SL1 and SL2): a)

log

Δt

log

a(creep)

relations; and b)

a(creep)

a(creep)

log

Δ

relations

a)

b)

100

1000

10000 100000 1000000

1E-10

1E-9

1E-8

1E-7

1E-6

1E-5

1E-4

SL02

Creep axial strain rate,

a(creep)

(%/sec)

Elapsed time,

t (sec

SL01

)

Test Name: FJM1104

1E-4 1E-5 1E-6 1E-7 1E-8 1E-9 1E-10

0.0

0.5

1.0

1.5

2.0

Test Name:FJM1104

SL02

Creep axial strain,

a(creep)

(%)

Creep axial strain rate,

a(creep)

(%/sec)

SL01