2102

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

th

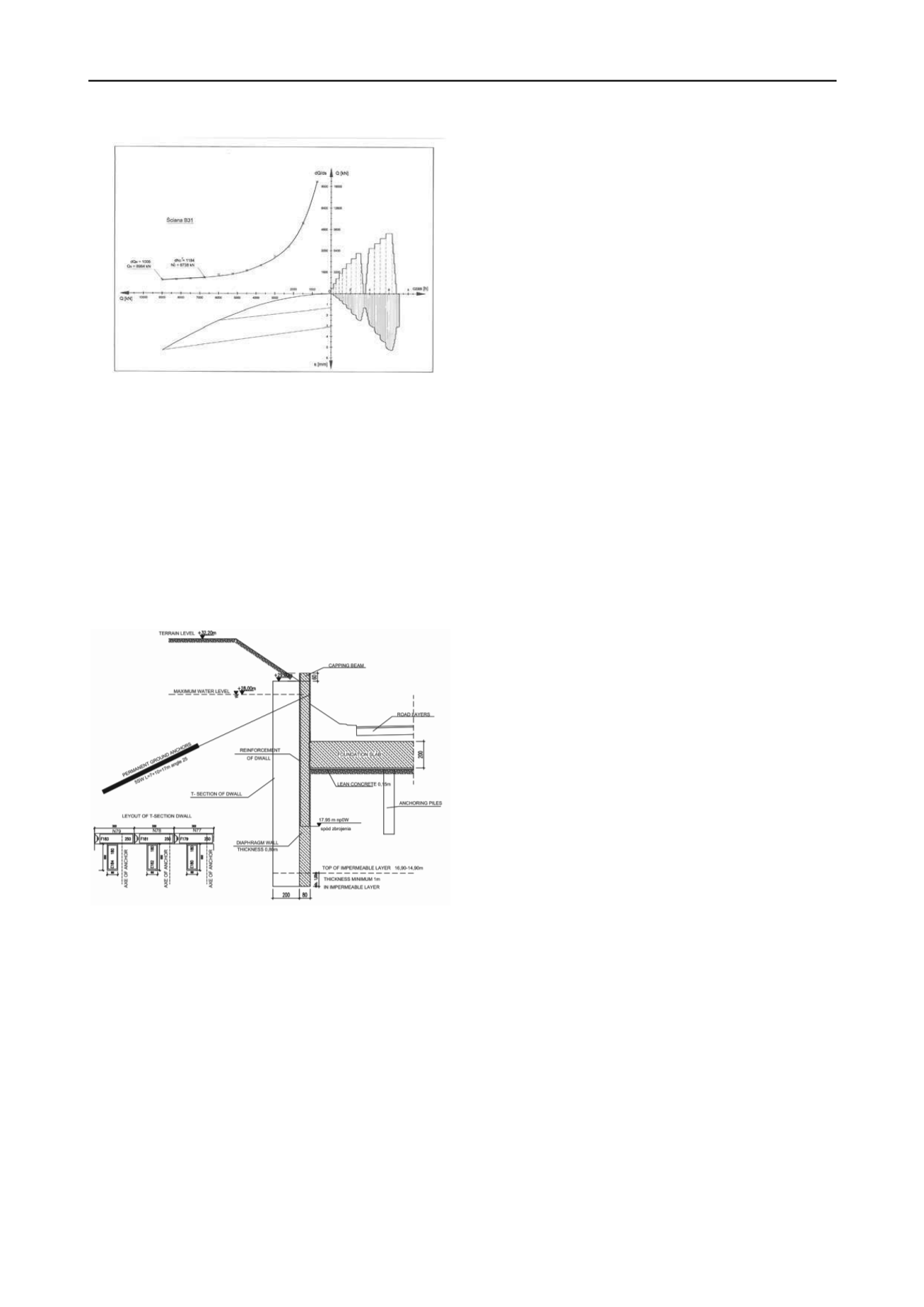

Fig. 5 Static load test result

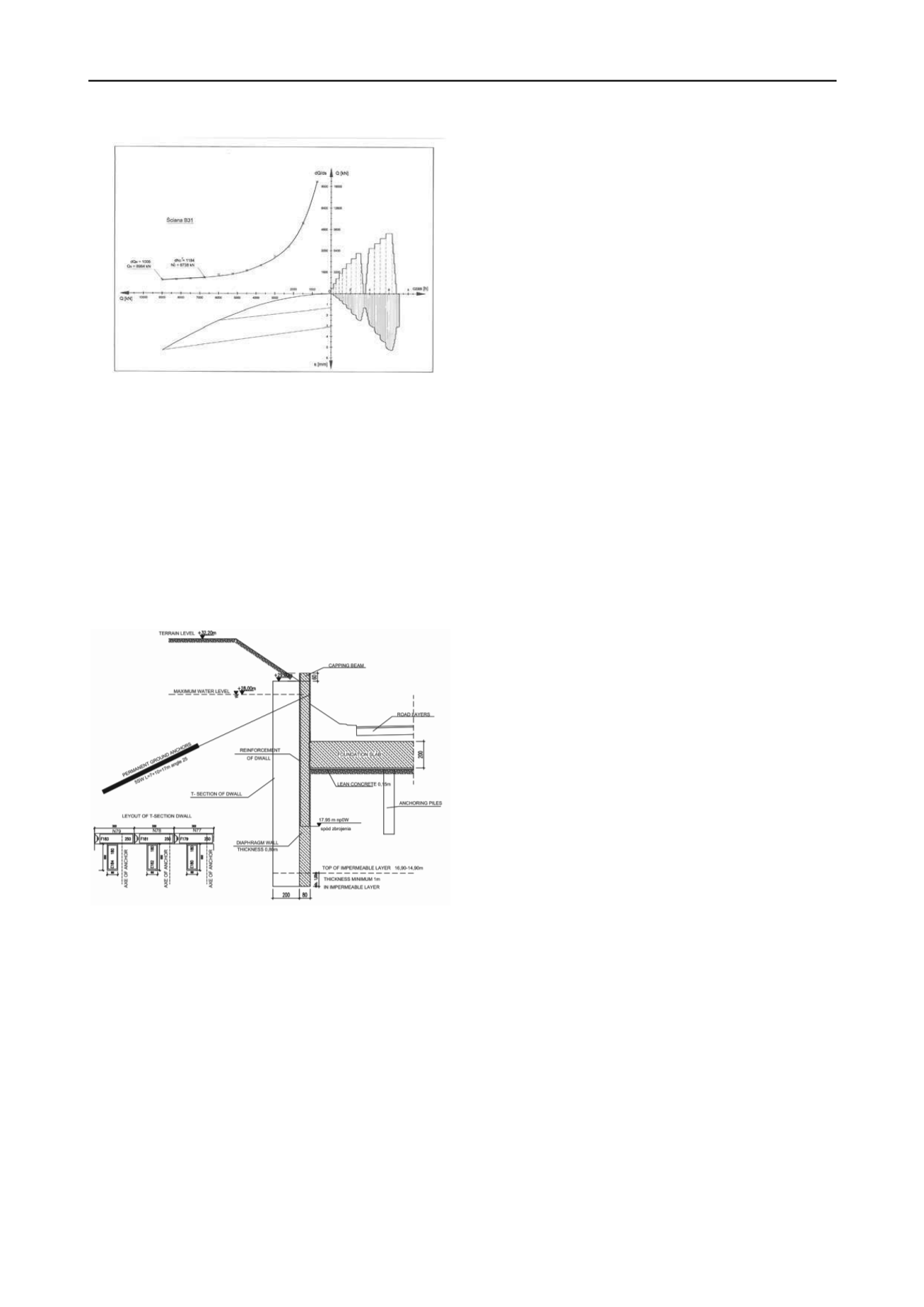

5 DIAPHRAGM WALLS AS VIADUCT ABUTMENTS

The contour of the casing of the lowest level of the junction

contained 4 viaduct abutments (viaduct W1 and W2). They

were designed as 80 cm thick T-shaped diaphragm walls.

Additional limitations were imposed for these fragments of

diaphragm walls with respect to both horizontal and vertical

displacements, caused by the selection of appropriate bearings.

Additional permanent anchors were implemented – fig. 6, in

order to minimize horizontal displacements of walls. In total, in

the area of viaduct abutments, 31 permanent ground anchors of

the 700kN capacity, were erected.

e code: PN-EN 1537 Execution of special geotechnical works.

etical

no

ding tests made for the barrettes

co

l road junction

construction. Most of the savings were obtained as a result of

significant shortening of construction works.

N-83/B-02482 Foundations. Bearing capacity of piles and piles

foundations.

Ground anchors.

6 SUMMARY AND CONCLUSIONS

The results of diapragm walls (as retaining walls) horizontal

displacements measurements confirmed the correctness of static

analysis of walls and prediction of their displacements, both

made during design stage. Maximum value of horizontal

displacement reached 10 mm for an 80 cm thick wall, anchored

with permanent anchors and it didn’t exceed neither theor

r permissible values. In the case of all other cross-sections,

displacements were smaller and reached up only to 8 mm.

The results of vertical loa

nfirmed the value of calculated theoretical bearing capacity

being 7600 kN to be correct.

There were no significant horizontal displacements of T-

shaped diphragm walls noted (measured).

The new solution applied in the execution design (replacing

the original one from the building permit design) was correct

and resulted in significant savings due to the use of only one

technology for the foundation and the retaining system

(diaphragm walls) of the entire 3 leve

7 REFERENCES (TNR 8)

Soletanche Polska Sp. z o.o. 2010Design of diaphragm walls for

Łopuszańska-Kleszczowa junction, Warsaw

Soletanche Polska Sp. z o.o. 2010Design of anchors for Łopuszańska-

Kleszczowa junction, Warsaw

Soletanche Polska Sp. z o.o. 2008Design of barrettes for Łopuszańska-

Kleszczowa junction, Bydgoszcz

GEOTECH Sp. z o.o. 2010Getechnical documentation for

Łopuszańska-Kleszczowa junction, Warsaw

PN-EN 1538 Execution of special geotechnical works – Diaphragm

walls.

PN-EN 1537 Execution of special geotechnical works – Ground

anchors.

P

Fig. 6 Typical T-shaped D-wall cross-section for the W2

viaduct abutment.

Due to the fact that abutments were founded in the same stiff

sandy clay layer as remaining barrettes made for the

foundations of pillars, additional, special loading tests were not

carried out for the T-shaped diaphragm walls. Bearing

capacities of T-shaped barrettes were calculated by interpolation

of the results of tests loadings of individual barrettes executed

in the near vicinity of abutments. Additional limitations were

imposed for T-shaped diaphragm walls with respect to

horizontal displacements. In order to comply with limitations

and minimize horizontal displacements of walls additional

permanent anchors were implemented. The design load of

permanent anchors was verified during acceptance tests. Each

anchor was stressed up to 125% of its design load and after

stabilization of creeping it was blocked at 80% of its design

load. There were no excess permanent or elastic strains of

anchor tendoms measured, in accordance with regulations of