2098

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1.3

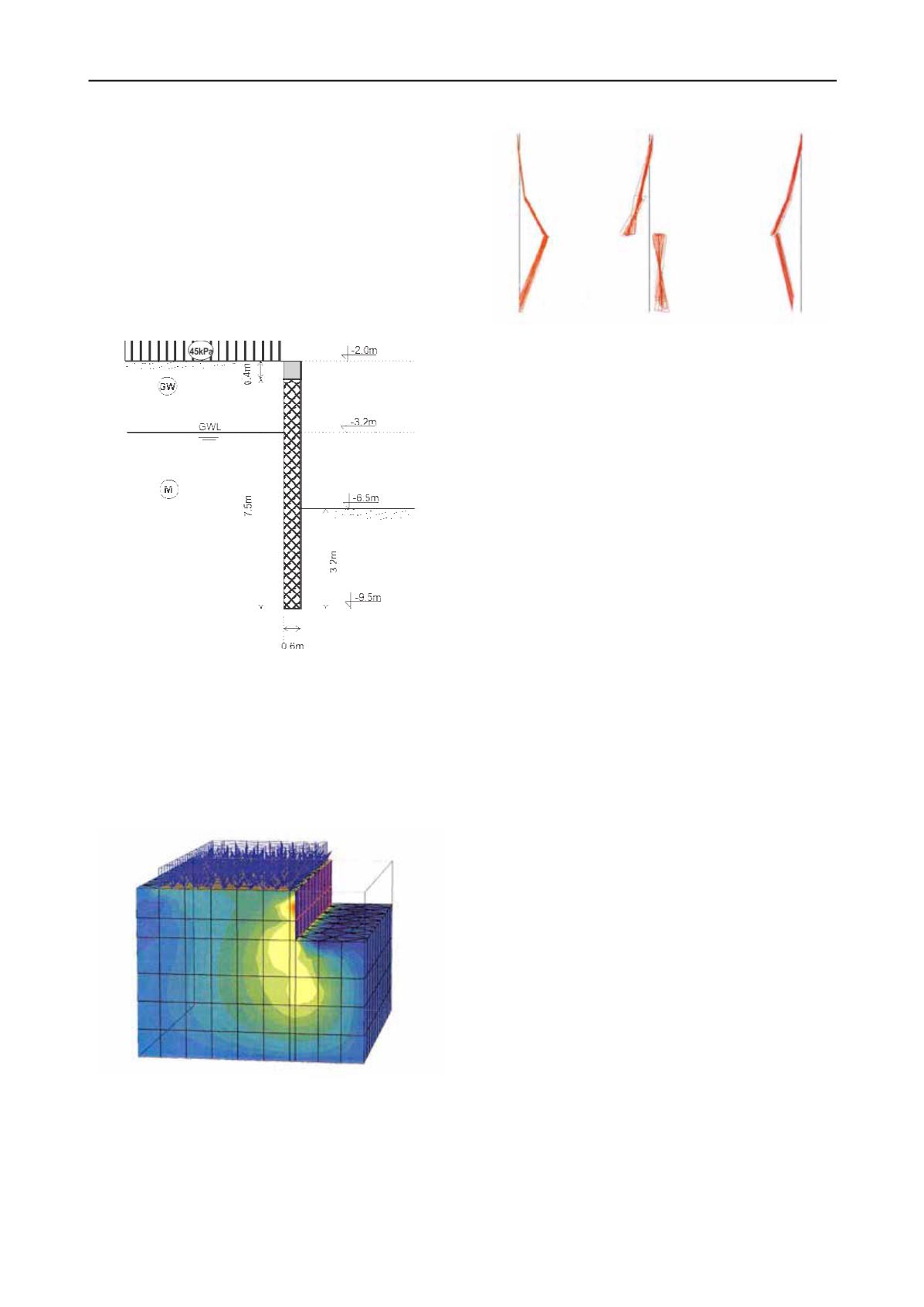

System of secant pile wall

For the same site (see Figure 5) an alternative solution has been

analysed with secant pile retaining wall to secure the excavation

pit (27.65x11.55m) but this time with depth of 6.5m. In this

scenario only two floors are planned to be constructed using a

temporary retaining structure. In the first phase the primary,

(reinforced concrete) piles with diameter of 0.6m and length of

7.5m spaced exactly 1.2m should be executed. In the next phase

the secondary (concrete) piles with the same diameter but

shorter depth of 5.5m are constructed. On the top they are

connected by a beam with dimensions 0.6x0.4m as shown in

Figure 9.

Figure 9. A plan of the secant pile wall in X1-X1 section.

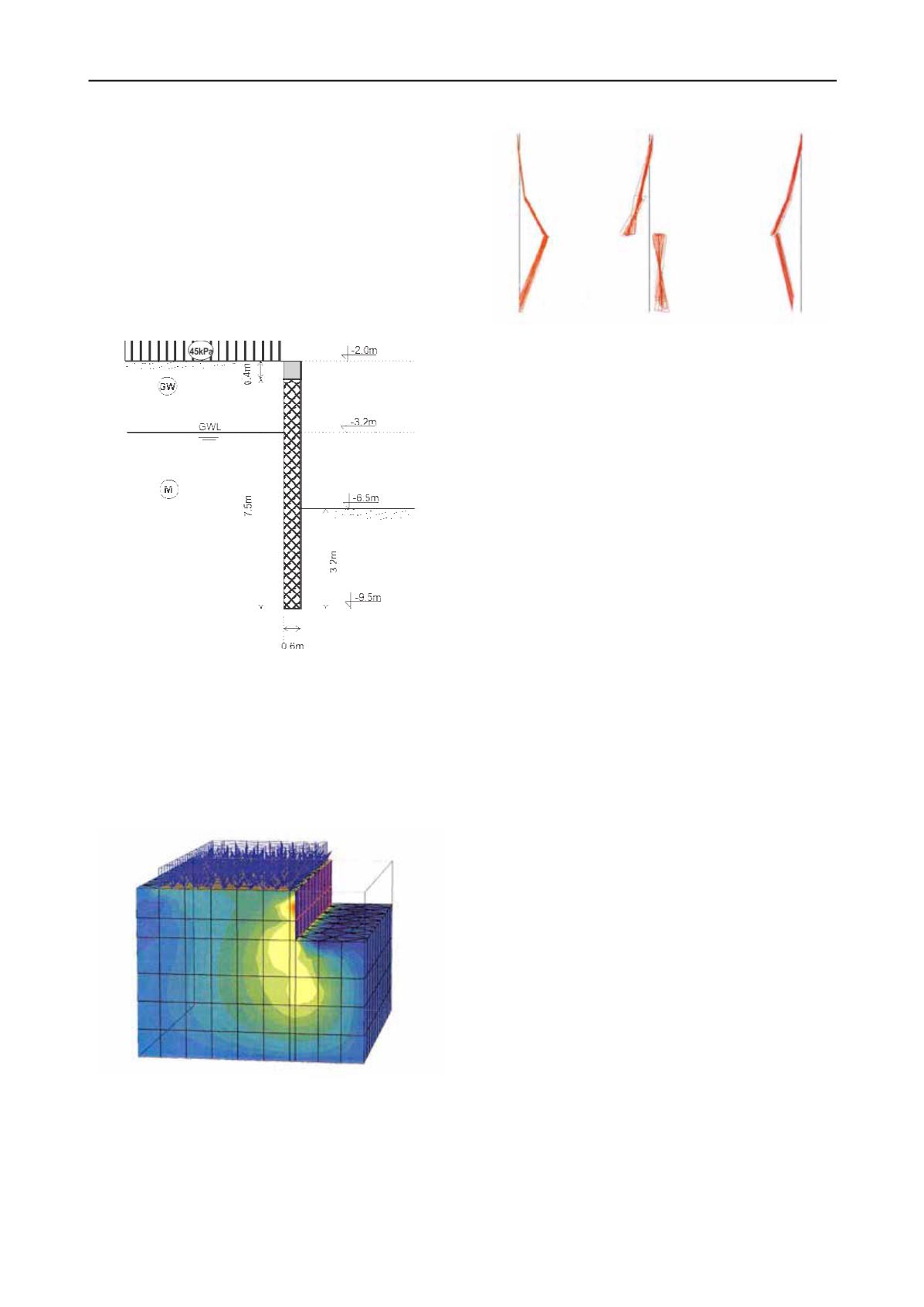

The problem is discretized using three-dimensional finite

element model where the soil profile is identical to the one

described in Table 2. For the spatial discretization volume

elements are used in combination with nonlinear-plastic

material definition for the soil and linear-elastic for the

concrete. The calculation is used to determine the stress-strain

behaviour of the soil-structure interaction system, hence

presented through the total displacement in Figure 10.

Figure 10. Total displacement of the soil-structure system in X1-X1

section.

A maximal earth pressure of 33.7kN/m

2

causes horizontal

displacement of 9.8mm, which have been considered as

acceptable. Furthermore, the diagrams of internal pile quantities

are presented in Figure 11.

(a)

(b)

(c)

Figure 11. Diagram of (a) Axial force, (b) Shear force and (c) Bending

moments in the pile.

The values of the maximal internal quantities: bending moment

M

=56.81kNm, shear force

Q

=-43.64kN and axial force is

N

=-114.8kN. The pile design has been made using interaction

(M-N) diagrams for C30/37 providing the following

reinforcement: longitudinal 14

ф

16 (28.2cm

2

) and stirrups

ф

8/20cm. Finally, the global stability is controlled where a

safety factor

F

s

=1.55 is obtained.

2 CONCLUSION

The solder H pile wall with lagging is rarely used in our

practice, although it is highly efficient and cost effective for

situations where there is no ground water. Also a greater depth

can be reached when combined with adequate supporting

system e.g. tieback. Nevertheless, in Skopje there are few

locations with low GWL. Although very formidable the systems

with diaphragm wall are seldom used, partially because there is

almost no experience nor there has been clear cost-benefit

analysis. For a long period of time it has been thought that the

costs are very height, which with the present study had proven

not to be the case. Combined with the top-down method of

construction where the wall is permanent structure according to

our analyses remains very cost effective solution. The secant

pile wall technique, in contrast, is very often used in our

practice, sometimes in combination with anchors when greater

depth is needed. It represents formidable solution but usually

takes a lot of the available space and construction time, also

brings high expenses since it is often a temporary structure.

Finally, when comparing all retaining structures we had come to

conclusion that the diaphragm wall represents a preferred

solution for underground construction in highly urbanized

(build-up) areas and situations with high ground water level as it

is usually the case in Skopje.

3 REFERENCES

German Society for Geotechnics (Deutsche Gesellschaft fur

Geotechnike.V.) 2003. Recommendations on Excavations, Ernst &

SohnVerlag fur Architektur und technische Wissenschaften GmbH

& Co. KG, Berlin, ISBN 3-433-01712-3.

Kempfert, H.G. and Gebreselassie, B. 2006. Excavations and

Foundations in Soft Soils, Springer-Verlag Berlin Heidelberg,

ISBN 540-32894-7.

Potts, D.M. and Zdravkovic, L. 2001. Finite element analysis in

geotechnical engineering: application. Imperial College of Science,

Technology and Medicine, Thomas Telford Publishing, Thomas

Telford Ltd, ISBN 0-7277 2753-2.

Moeller G. 2012. Geotechnik. Grunbau, Bauingenieur-Praxis, 2 Ed. Erst

& Sons, A Wiley Company ISBN: 978-3-433-02976-3.

EN 1997-1:1994 Eurocode 7: Geotechnical design - General rules

EN 1538:2000 Execution of special geotechnical works – Diaphragm

walls