2090

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

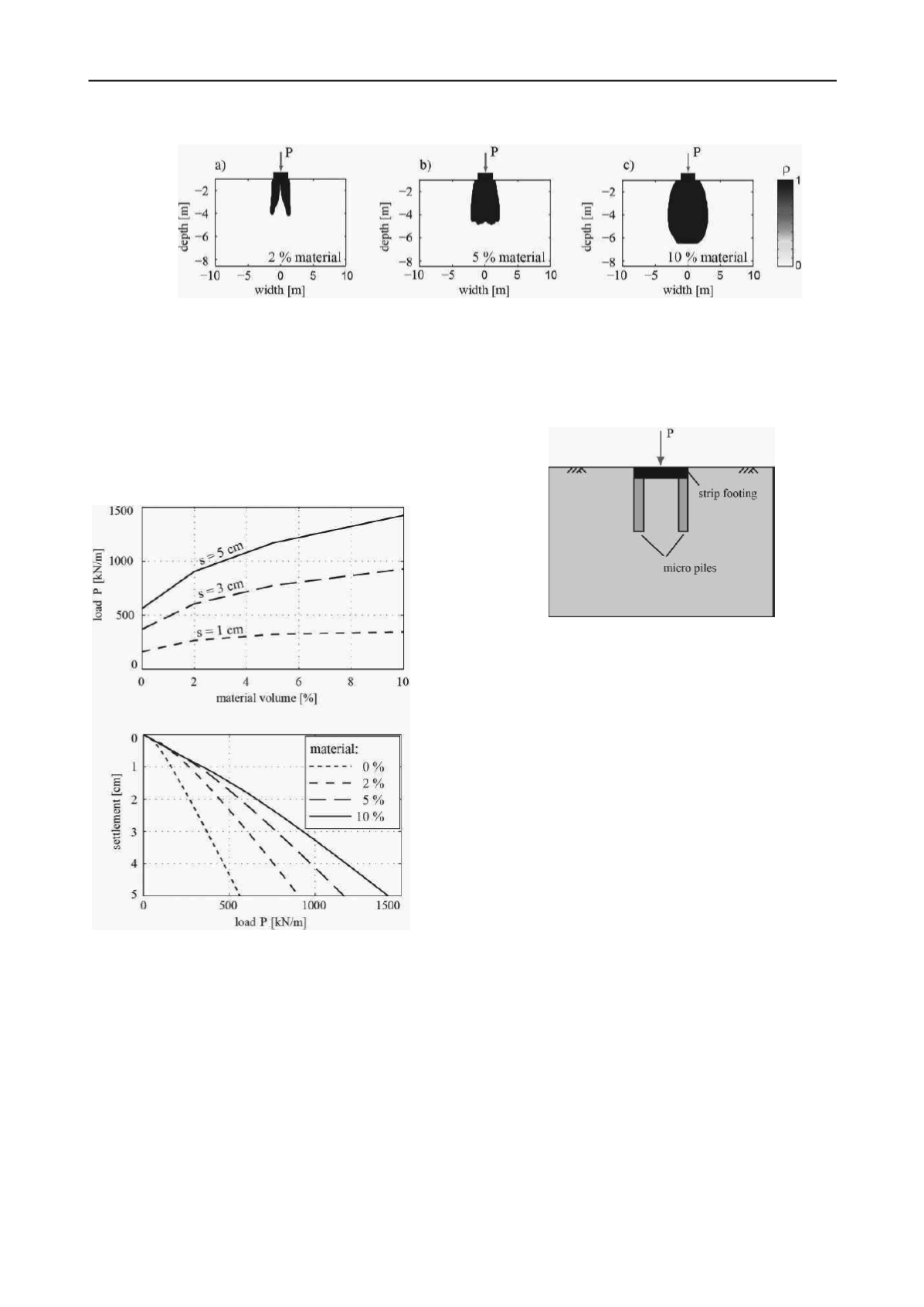

The influence of the material volume on the improvement is

shown in Figure 8. Figure 8 top shows the material volume over

the vertical load P at different settlements. The applicable load

at a settlement restriction about 1 cm cannot be significantly

improved using more than 2% material volume. Regarding

higher settlement restrictions, the increase of the material

volume also increases the applicable load P.

The same results can be obtained from the load settlement

curves of the improved foundations in Figure 8 bottom. The

main improvement is reached with a material volume about 2%.

1.5

Practical realization

The practical realization of the optimized topologies can be

quite difficult. The optimized topologies of the presented

example can be realized using the jet grouting method. This

method allows the realization of every possible topology

restricted by the minimum diameter of a jet grouting body.

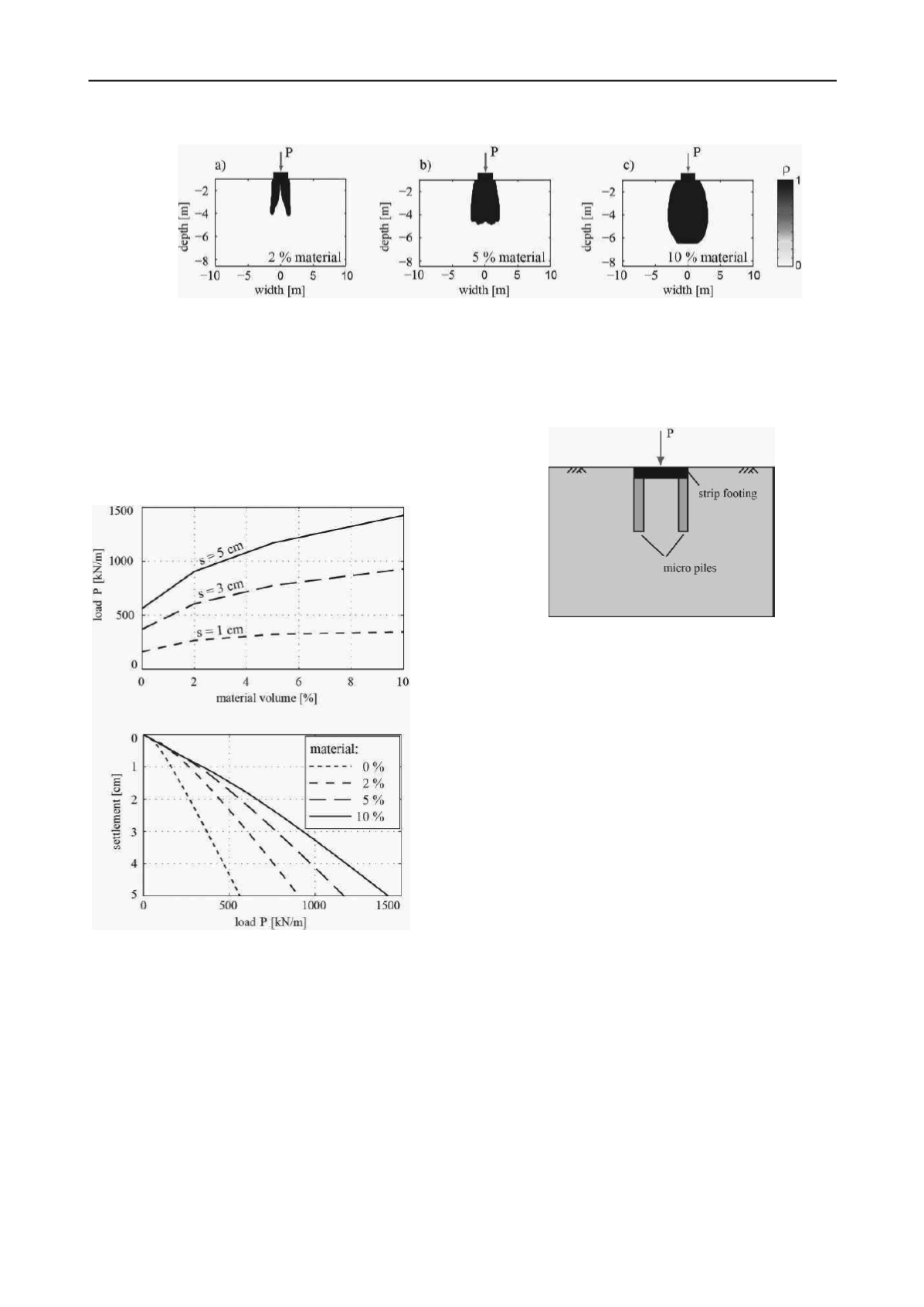

Another possibility to realize such topologies is the

interpretation of the topologies and the conversion of the

topology into standard geotechnical construction parts. The

realization of the topology with 2% material can be done using

a classical strip foundation topology in combination with micro

piles, see Figure 9.

2 CONCLUSION

The application of topology optimization in geotechnical

engineering was presented. The applied SIMP-Method is

suitable for geotechnical problems. In the presented example,

the settlements of a strip foundation could be reduced up 66%.

Topology optimization in geotechnical engineering has a

great potential and can lead to innovative and efficient designs.

3 REFERENCES (TNR 8)

Allaire G., De Gournay F., Jouve F. And Toader A.-M. 2005. A level-

set method for shape optimization.

Controal and Cybernatics

34.

Bendsøe M.P. 1995. Optimization of structural topology, shape and

material. Berlin, Heidelberg, New York

Grabe J., Kinzler S., Pucker T. And Mardfeldt B. 2010. Untersuchung

des Tragverhaltens und der Anwendbarkeit numerischer

Optimierungsverfahren für Kaikonstruktionen.

Tagungsband der

31. Baugrundtagung 2010 in München,

123-129

Grabe J., Pucker T., Busch P. 2012. Non-linear numerical model for the

design process of deep foundations with regard to effects of pile

installation.

Proceedings of 9th International Conference on

Testing and Design Methods for Deep Foundations 2012 in

Kanazawa/Japan,edited by T. Matsumoto

, 55-64

Kinzler S. 2007. Entwurf einer Pfahlgründung unter Anwendung der

Mehrkriterien-Optimierung.

Der Bauingenieur

82, 367-379.

Sigmund O. 2001. A 99 line topology optimization code written in

Matlab.

Structural and Multidisciplinary Optimization

, 21, 120-127

Niemunis A. and Herle I. 1997. Hypoplastic model for cohesionless

soils with elastic strain range.

Mechanics of Frictional and

Cohesive Material

, 2, 279-299

Pucker T. and Grabe J. 2011. Structural optimization in geotechnical

engineering - basics and application.

Acta Geotechnica

, 6, 41-49,

DOI: 10.1007/s11440-011-0134-7

Von Wolffersdorff P.-A.. 1996. A hypoplastic relation for granular

materials with predefined limit state surface.

Mechanics of

Frictional and Cohesive Material

, 1, 251-271

Figure 7. Optimized foundations with a) 2% material volume, b) 5% material volume, c) 10% material volume

Figure 8. top: load P over material volume at different settlement

restrictions; bottom: load-settlement curves of the optimized foundation

topologies

Figure 9. Possible practical realization of the topology with 2% material

volume