2100

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

horizontal displacements and settlements were measured and

compared to theoretical values calculated in the design stage.

It has allowed an assessment of the correctness of the solution.

2 GEOTECHNICAL AND HYDROLOGICAL

CONDITIONS

The ground in the land plot consists mainly of Quaternary

formations: river sediments and glaciofluvial deposits as well as

glacial deposits.

In the entire area involved in the investment,

the near-surface layers below man-made fills consist of

medium-dense and dense sands and gravels reaching down to

the max. depth of 18.8 m. Below (the layer roof from 10.6 to -

18.8 m), there are glacial clays, deposited in the form of stiff

sandy clays, clayey sands and, locally, silty clays.

The layer of

anthropogenic soils is not very thick: maximum thickness:

2.2m, average thickness: about 0.5-1.00 m.

Within the entire area, a continuous ground water table was

found in the layer of glaciofluvial sands. The ground water table

was located at about -4.5 m below the ground level.

Occasionally, the water table was confined by lenses of

cohesive soils.

3 DIAPHRAGM WALLS AS A RETAINING WALL

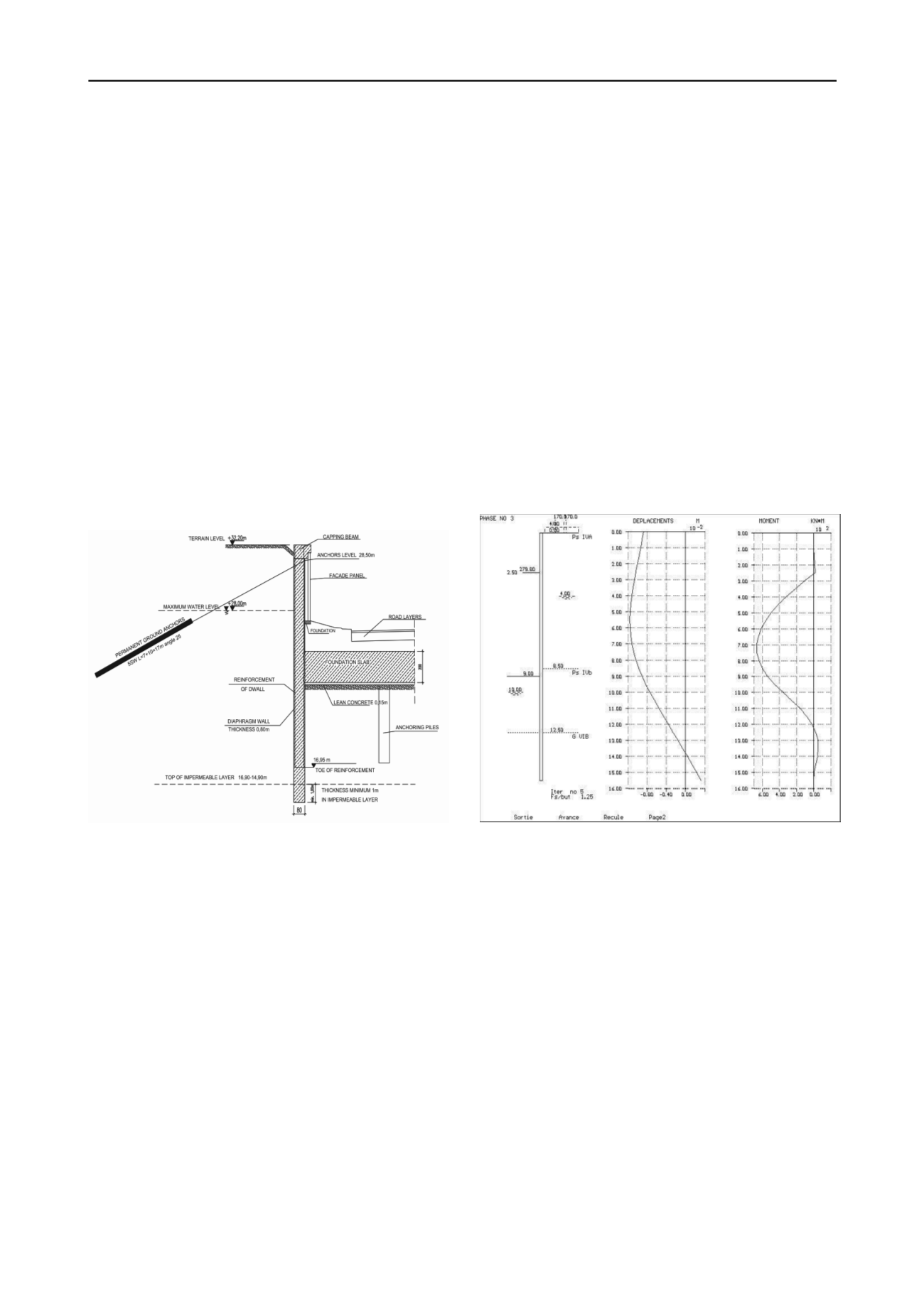

Fig. 2 Typical cross-section of the excavation wall; 80cm thick

diaphragm walls, anchored using permanent anchors.

Due to variable embedding of the excavation below the ground

level, down to the maximum depth of 10 m below the ground

level, diaphragm walls with 3 different thickness values were

implemented, namely 60 cm, 80 cm and 100 cm. Moreover,

different types of protective measures were implemented to

ensure stability of casing walls, i.e:

-

temporary ground anchors, 600 kN capacity (cross –

section 2-2),

-

permanent ground anchors, 600 - 700 kN capacity

(cross-sections 3-3, 4-4, 5-5),

-

permanent ground anchors in the area of T-shaped D-

walls, 700 kN capacity (cross section 6-6).

Some parts of walls reamined not supported (cantilever

walls) due to the small hight of excavation (cross-section 1-1) or

possible colisions with pile foundations outside the wall (cross-

section 7-7).

In total 148 ground anchors were executed (18 temporary

and 130 permanent) and 31 permanent ground anchors for

abutments.

Diaphragm walls along the entire perimeter of the facility

(including the transversal walls) were embedded at least 1 m

down into the impermeable layer, in order to minimise the

inflow of water into the excavation (fig 2). Due to unbalanced

hydrostatic pressure, the ground slab was anchored with

displacement piles in its central part in the deepest excavation

(fig 2.).

Diaphragm walls were designed to resist loads resulting from

soil pressures and from service loads at the ground surface

generated by vehicles and stored materials, amounting to

q=12,0 kPa in the zone removed by at least 1.5 m from the wall

face, and loads generated by heavy traffic, amounting to q=30

kPa. Additionally, the design considered a load generated with

vehicle K located on the roadway located in close vicinity of the

diaphragm wall, in compliance with standard PN-85/S-10030

Bridges. Loads.

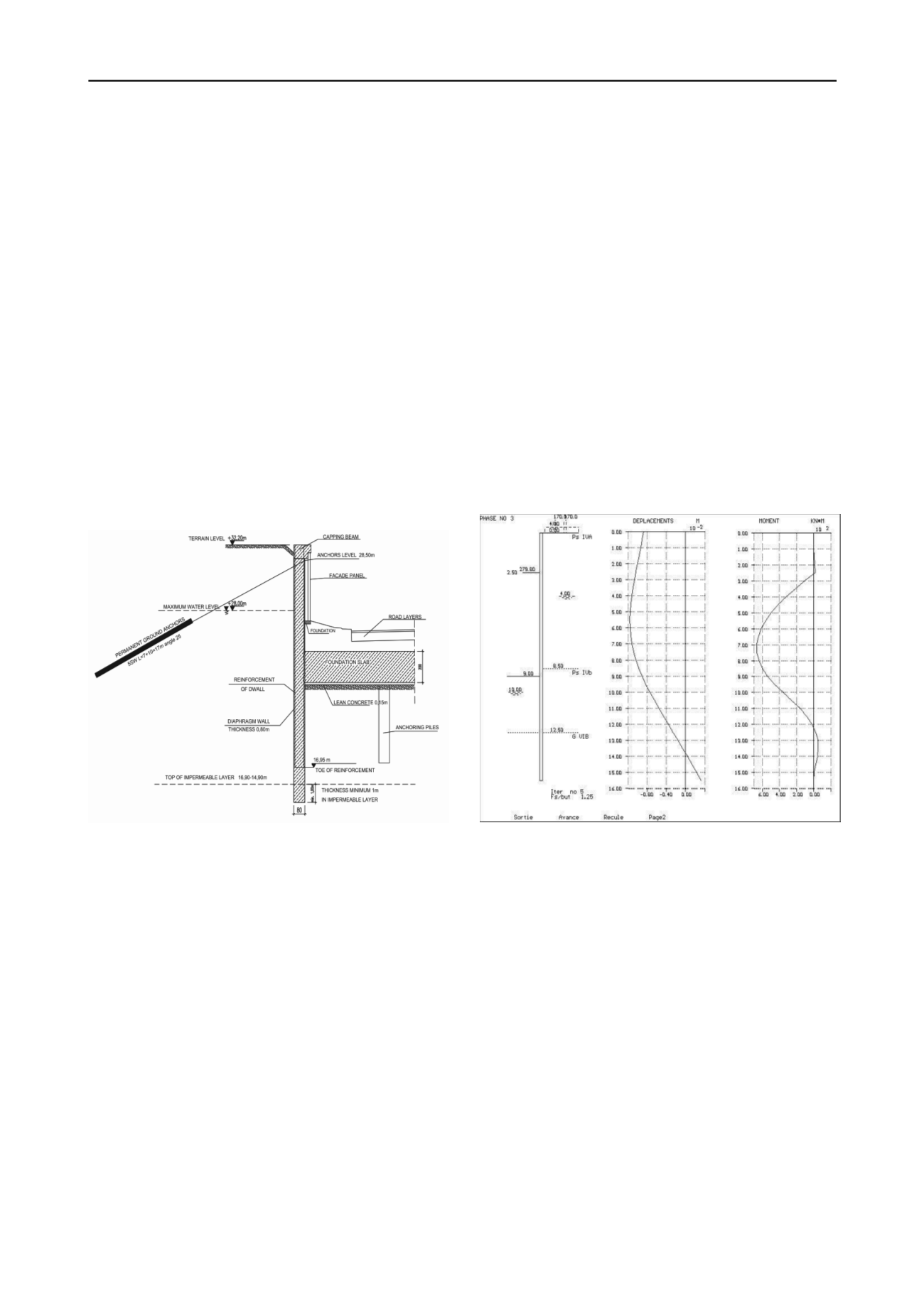

Static analysis of diaphragm walls were made using

dependent pressures method (PAROI). 7 typical calculation

cross-sections were verified. Typical results of calculations –

bending moments and displacements – are shown at fig. 3.

Maximum theoretical values of horizontal wall displacements

are as follows:

- cantilever D-wall - 6 mm;

- D-wall and temporary ground anchors - 15 mm;

- D-wall and permanent ground anchors - 12mm;

- T-shaped D-walls - 8mm.

Corresponding bending moments amount to 180 kNm/m up

to 700 kNm/m.

Fig. 3 Theoretical values of bending moments and horizontal

displacements for 80cm thick D-wall with permanent ground anchors

(corss-section 5-5) in the final construction stage.

Benchmarks for geodesic measurements were located on the

capping beam of diaphragm walls, spaced every 50 m at the

maximum. Measurements were carried out for particular stages

of execution of works on site, at least once every month or more

frequently.

Construction stages were as follows:

-

site preparation, sub-base preparation, construction of

guide walls and D-walls with RC capping beam –

reference measurement,

-

excavation 0,5m below the anchoring level –

measurement 1,

-

execution and stressing of ground anchors –

measurement 2,

-

final excavation – measurement 3,

-

verification of displacemants during the execution of

driven piles – subsequent measurements.

Particular attention was paid to measurements of wall

displacements in the vicinity of works consisting in driving

displacement piles in, in order to anchor the ground slab. In the

view of the presence of a layer of silty sands, designers were

concerned about the impact of dynamic pile driving on the load-

carrying capacity of ground anchors, whose bearing plates are