2648

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4 INNOVATIVE SOLUTIONS FOR COASTAL

HYDRAULIC ENGINEERING

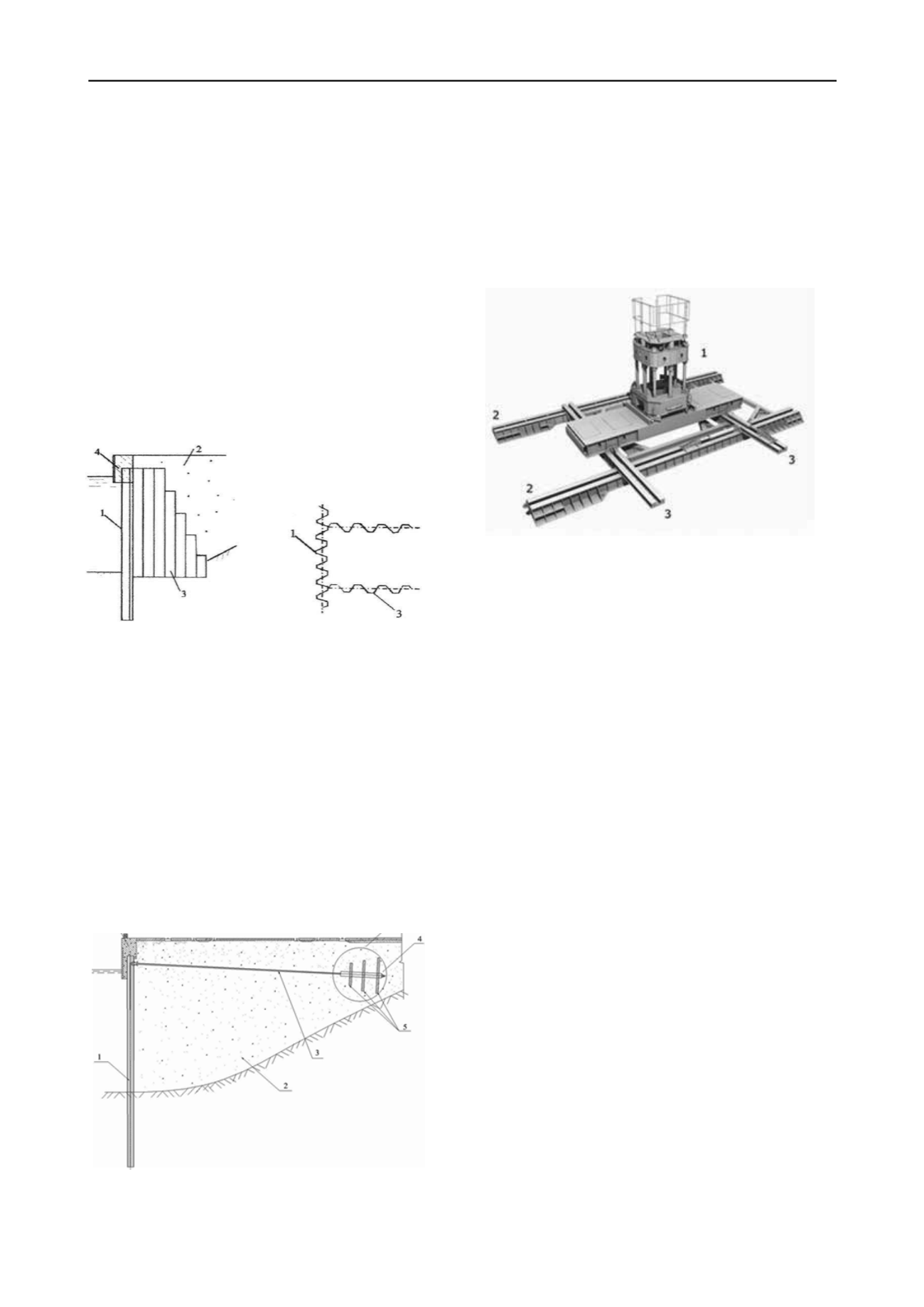

A new structure of the retaining wall has been worked out to

provide, firstly, resistance to heavy loads stipulated by soil

pressure behind the coastal sheet piled wall and, secondly,

simplifying of construction technology for deep water quay wall

due to absence of traditional anchor devices. Retaining wall

(Fig. 4) includes steel sheet piles installed along the structure,

soil backfilling behind the wall and transversal sheet piled rows

(counterforts) connected with axial wall. Counterforts are made

of sheet piles of different length and have a shape of rectangular

trapezoid. The length of the sheet piles in counterforts is

decreased according to the distance from the axial wall and

width of the transversal rows is increased downwards. Sheet

piles’ heads are joined by the cap. In such structure the idea of

counterforts is not only to increase a rigidity of the retaining

wall while withstanding the applied loads but also to reduce

effectively soil pressure behind the wall.

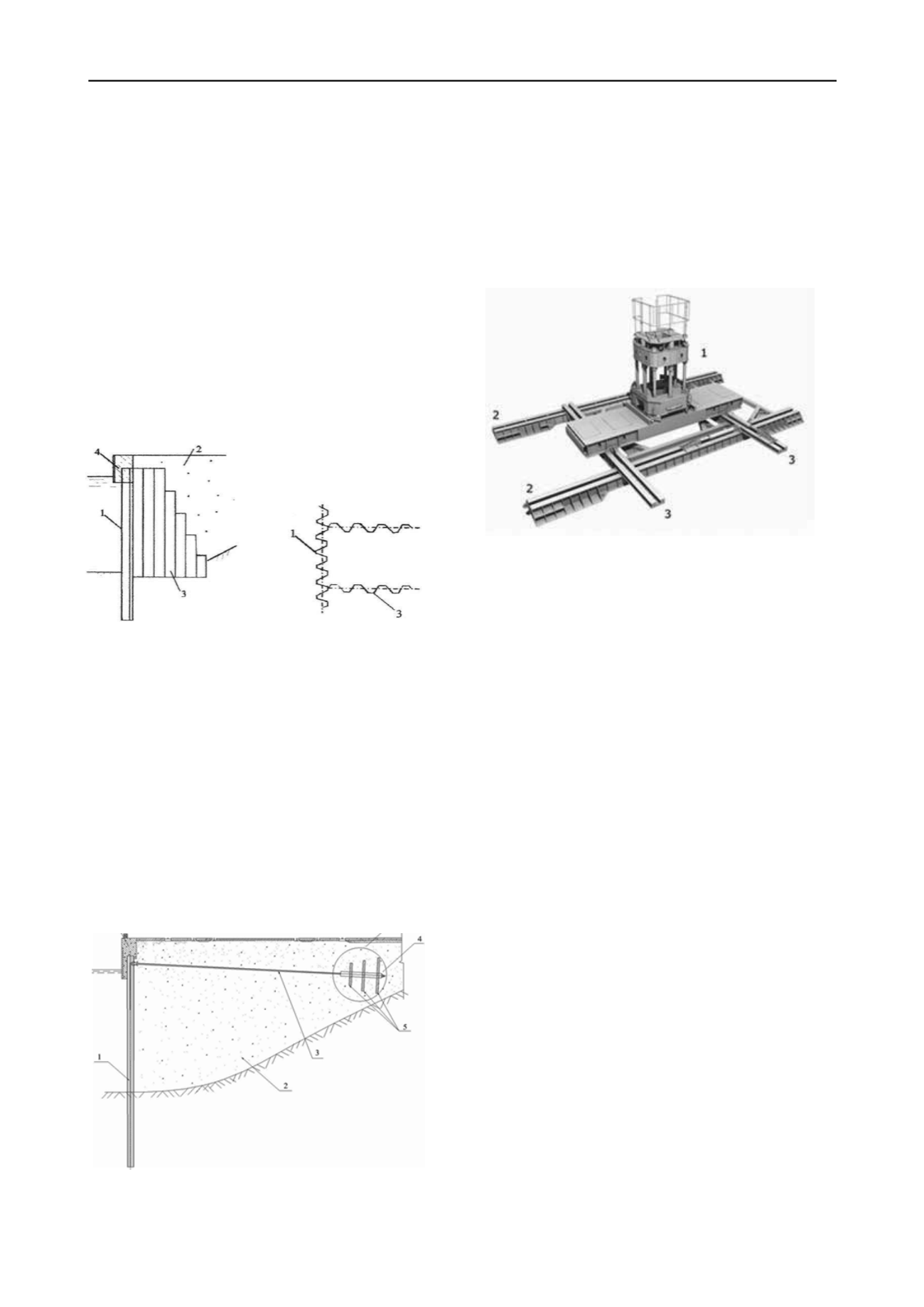

The basic research for full-scale physical modeling on press-

in and extraction equipment was based on the Modular Piling

System. This multifunctional equipment has been developed

with the intended purpose of implanting prefabricated

construction elements using the press-in method. The piling

system is equipped with the original hydraulic piling machine

(Fig. 6) with wedge-operated clamps (testing devise) and a

modular coordinating skidding system (MKS).

Figure 6. Modular section of the piling system MKS: 1 – press-in piling

machine; 2 – longitudinal guides (skid tracks); 3 – transverse guides

(cross slide).

Figure 4.

Sheet piling wall with counterforts: a

– cross-section; b –

plan. 1 – axial sheet piling; 2 – soil backfilling; 3 – sheet piled

counterforts; 4 – cap.

A new construction of the bulkhead is worked out to increase

the bearing capacity of the coastal protection wall or quay wall

as well as to reduce their material consumption (Fig. 5). The

structure incorporates the front wall and soil backfilling behind

it. Anchor bearers are made of “comb” type as several small

anchor plates fixed along the rigid core. Anchor force is taken

by all plates of the comb simultaneously. It provides increasing

of the bearing capacity both of the anchorage and of the

structure in whole (keeping the same material consumption for

the anchorage as at the traditional solutions with one large

anchor plate). On the other hand proposed structure may

provide decreasing of the material consumption (keeping the

same structure’s bearing capacity as at the known facilities).

In terms of its impact capability the piling machine is

completely quiet and vibrations in the ground are at an absolute

minimum allowing for the machine to work on certain highly

sensitive ground areas, extremely small spaces, and in historical

preservation areas. The strategic technological advantages of the

piling system are high productivity, precision and quality

control.

Depending on the features of the project, location of the piles

in terms of engineering and geological conditions of the site,

pressing construction elements into the ground could be

provided with the flow-line and coordinating installation

methods.

REFERENCES

Bruce D.A. An introduction to the deep soil mixing methods as used in

geotechnical applications. Report FHWA-RD-99-138 / D.A. Bruce.

– U.S. Dept. of Transportation, Federal Highway Administration,

2000. – 143 p.

Characteristics of manmade stiff grounds improved by drill-mixing

method / M. Zotsenko, Yu. Vynnykov, I. Lartseva, V. Shokarev, V.

Krysan // Proc. of the 15

th

European Conf. on Soil Mechanics and

Geotechnical Engineering “Geothechnics of Hard Soils – Weak

Rocks”. – Athens. – 2011. – P. 1097 – 1102.

Deep mixing research results in under water conditions / [W.F. Van

Impe, R.D. Verástegui Flores, P.O. Van Impe et. al.] // Proc. of the

16th Intern. Conf. on Soil Mechanics and Geotechnical Engineering

(Osaka, 2005). – Millpress Science Publishers Rotterdam, 2005. –

V. 3. – P. 1275 – 1278.

Larsson S. Mixing processes for ground improvement by deep mixing.

Doctoral thesis / S. Larsson. – Stockholm: Royal Institute of

Technology, 2003. – 218 p.

Figure 5. Anchored bulkhead with anchor bearer of new “comb” type:

1 – sheet piling; 2 – backfilling; 3 – tie-rod; 4 – rigid core; 5 - anchor

plates.

Stress-strain state of the system “base-strip foundation” at elimination

of excessive

tilts of buildings

/

V. Shokarev, V. Shapoval, V.

Chaplygin, R. Samchenko, D.Volkov

//

Proceedings of the 17th

International Conference on Soil Mechanics and Geotechnical

Engineering, Alexandria, Egypt, 2009. - Published by IOS Press

under the imprint Millpress, 2009. – V. 1. – P. 680-683.