3405

Technical Committee 307 + 212 /

Comité technique 307 + 212

the highly conductive stainless steel cell with the controlled

water bath was accounted for as a convection-type boundary

condition of the problem. This heat flux was assumed to be

proportional to the difference between the temperature of the

cell and the temperature of the water bath at each boundary

node, through a convection coefficient

h

. Thermal optimisation

was then aimed at identifying the values of the saturated thermal

conductivity

and the convection coefficient

h

. Calculations

were performed for different combinations of

and

h

. For each

of them, a measure of the least squares difference between

temperature simulation results and temperature experimental

measurements

was computed for different elapsed times. The

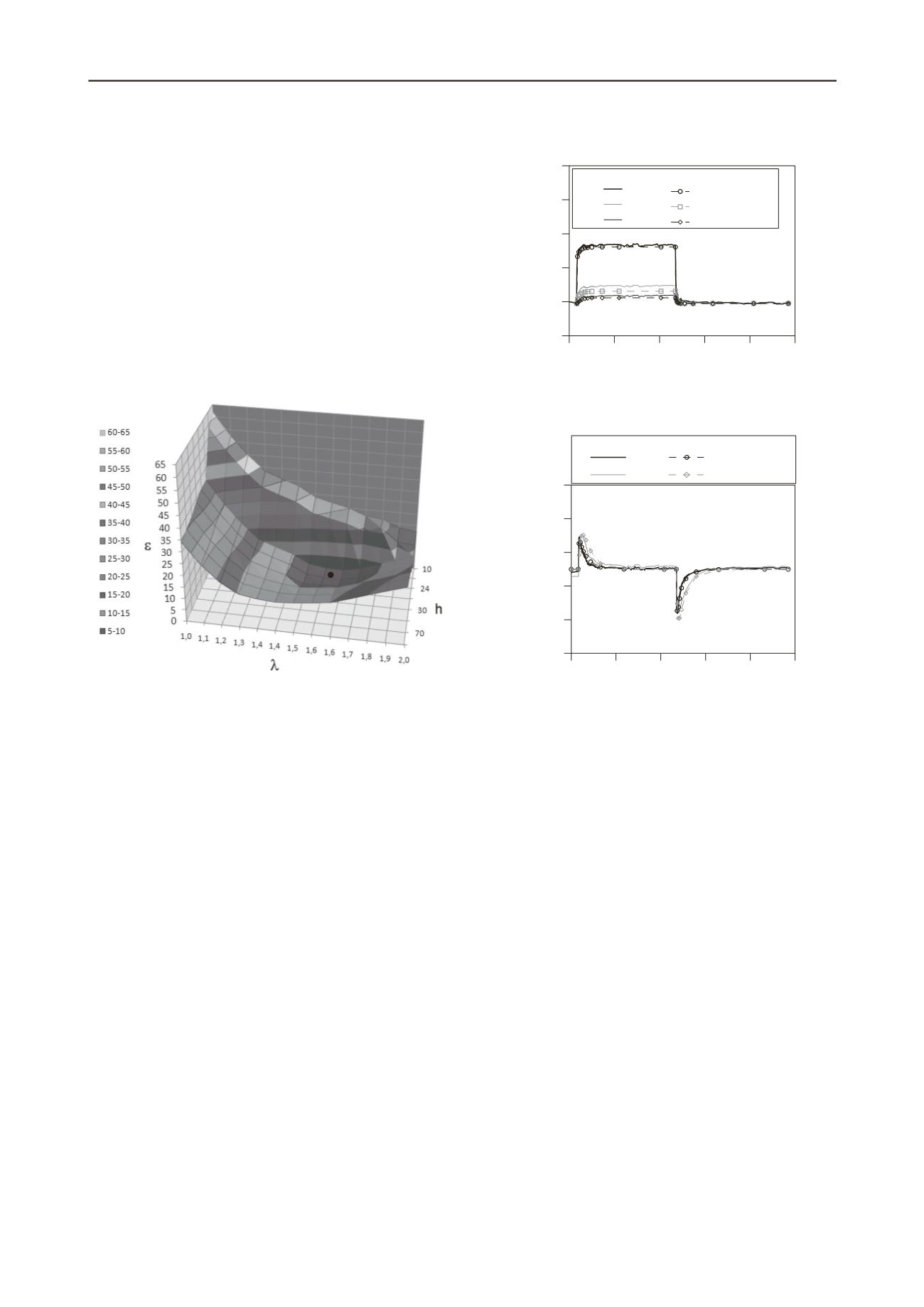

three-dimensional plot in Figure 4 shows the least squares

differences

between simulation results and experimental

observations

The best agreement was obtained for parameters

=1.6 Wm

-1

K

-1

and

h

=24 Wm

-2

K

-1

.

n of thermal conductivity

and

nvection coefficient

h

(Lima 2011).

irectly measured

parameters from independent laboratory tests.

xperime

eatures of the hydro-thermal coupling

under the test conditions.

Figure 4. Three-dimensional graph showing the differences in

temperature between observations and calculations in the back-analysis

of the heating pulse test. Determinatio

co

Back-analysed thermal parameters were used to study the

coupled thermal and hydraulic results. Water permeability and

elastic soil parameters used in the simulations, which are

reported in Table 1, were obtained from independent tests.

Controlled-gradient tests at different temperatures and constant

volume conditions for water permeability, as well as small-

strain shear moduli with resonant column and bender element

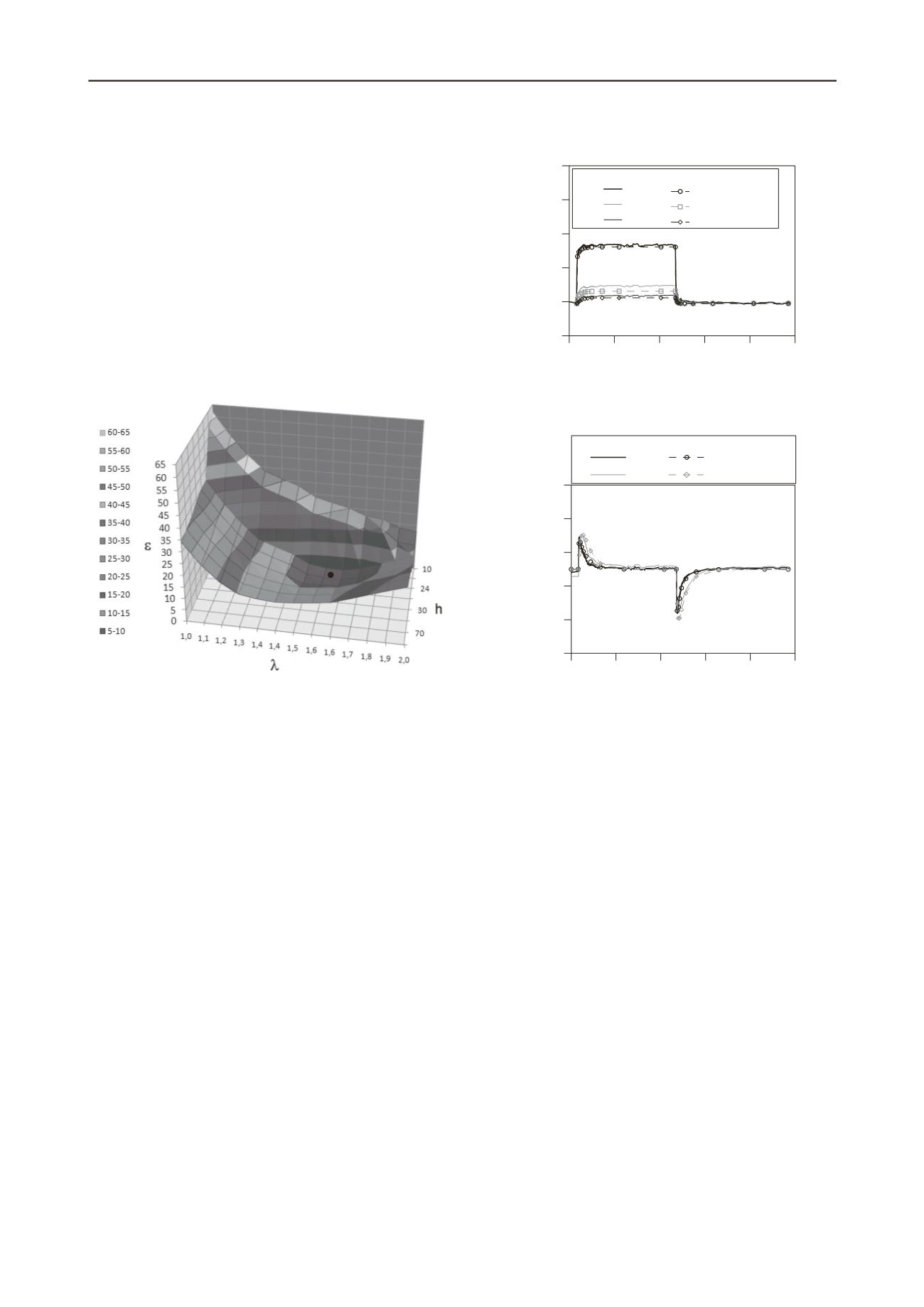

tests, have been reported by Lima (2011). Figure 5 displays the

time evolution of temperature and pore water pressure

(experimental and simulated results) during the same heating

and cooling paths presented in Figure 2. A good agreement is

observed in the pore water pressure response, which shows the

consistency between the back-calculated and d

Figure 5. Time evolution of temperature and pore water pressure:

ntal and simulated results (Lima 2011).

e

5 CONCLUSIONS

A series of heating and cooling paths were performed on Boom

Clay –a reference host formation for potential geological

disposal of ‘High-Level Radioactive Waste’ in Belgium– to

study the impact and consequences of thermal loads on this low-

permeability clay formation. Tests were performed in a fully-

instrumented heating cell –with several thermocouples and

pressure transducers– under constant volume and controlled

hydraulic boundary condition: constant water pressure at the

bottom drainage and top end with no flow condition. Selected

results of a comprehensive experimental programme on intact

borehole samples have been presented and discussed in terms of

the joint measurements of temperature and pressure changes

during the application of heating-cooling cycles.

Thermal and hydraulic results were calibrated and simulated

using coupled thermo-hydro-mechanical analyses performed

with a finite element code (CODE_BRIGHT). In particular, the

thermal conductivity of the clay was determined by back-

analysis of the thermal response. The coupled thermal and

hydraulic results were also successfully simulated using

parameters that had been back-calculated from previous heating

pulse tests and also directly from independent laboratory tests.

An overall examination of the results obtained allows the

identification of the main f

upper valve closed

backpressure 1MPa

P = 9.58 W

0 0.4 0.8 1.2 1.6 2

Time (days)

0

0.4

0.8

1.2

1.6

2

Pore water pressure (MPa)

Stage 3

Pw

1

Pw

2

Pw

1

bottom 25 mm

Pw

2

top 75 mm

Experimental results Numerical simulations

0 0.4 0.8 1.2 1.6 2

Time (day)

0

20

40

60

80

100

Temperature (ºC)

Stage 3

Experimental results

Numerical simulations

T

1

T

2

T

3

T

1

heater

T

2

bottom 25mm

T

3

top 75mm

(a)