3011

Technical Committee 215 /

Comité technique 215

,

L L

L L

L t

nS

v

f

t

z

(4)

,

G G

G G

G t

nS

v

f

t

z

(5

)

where

ρ

G

and

ρ

L

are liquid density and gas density respectively,

n

is the porosity which is determined by

m

sd

and

ε

,

S

L

and

S

G

are

liquid saturation and gas saturation respectively,

v

L

and

v

G

(m/s)

are liquid velocity and gas velocity respectively.

Mechanical compression of MSW is expressed by the one-

dimensional compression model expressed as Eq.1. The

effective stress

σ’

is expressed as Bishop’s equation for

unsaturated soils (Bishop 1959).

Main governing equations of the BHM coupled model are

shown as Eqs.1-5.The BHM coupled model is numerically

solved by the finite difference method and Gauss-Newton

method.

Based on Chen et al. 2009 and Reddy et al. 2008, two

hypothetical waste samples with a height of 5m are studied for

MSWs in Qizishan landfill, China and Orchard Hills landfill,

USA, respectively. As shown in Figure 4, top boundary is

impervious for liquid but free for gas flow, and the bottom

boundary is impervious for gas but free for liquid flow. The

total stress is set to be zero at the top boundary, and

compression strain is set to be zero at the bottom boundary.

Each element is 0.5m high, and the time step is 10

-5

day

-1

.

Parameters applied are shown in Table 2. Gas pressure,

leachate/gas production and settlement are analysed through the

BHM coupled model.

Figure 4. Schematic diagram of a hypothetical waste sample

Table 2. Parameters applied in the BHM coupled model

m

ds

1

/

m

s

0

m

ds

2

/

m

s

0

m

ds

3

/

m

s

0

w

0

(wet)

0.35*

0.20*

0.10*

0.60*

0.05

#

0.25

#

0.20

#

0.44

#

f

water

d

S

γ

0

(kN/m

3

)

e

0

1.0*

1.87*

7.5*

3.0*

1.0

#

0.85

#

5.0

#

1.4

#

C

C

’

C

C∞

’

σ

0

’

(kPa)

ε

tS

(

σ

0

’

)

0.25*

0.17*

10*

0.38*

0.28

#

0.17

#

10

#

0.20

#

m

vG

n

vG

α

vG

(m

-1

)

γ

vG

0.26*

#

1.35*

#

25.6*

#

3.0*

#

μ

L

(kgm

-1

s

-1

)

μ

G

(kgm

-1

s

-1

)

Mol

G

(kgmol

-1

)

R

(m

3

PaK

-1

mol

-1

)

1.0×10

-3

*

#

1.4×10

-5

*

#

0.03*

#

8.314472*

#

c

1

’

(day

-1

)

c

2

’

(day

-1

)

c

3

’

(day

-1

)

c

(day

-1

)

0.00023*

#

0.00013*

#

0.00003*

#

0.0016*

#

k

0

(m

2

)

θ

S

θ

r

η

10

-11

*

#

0.75*

#

0.035*

#

-0.11*

#

T

(K)

g

(ms

-2

)

ρ

L

(kgm

-3

)

P

a

(Pa)

303*

#

9.8*

#

994.13*

#

101320*

#

Note: * is for MSWs in Qizishan landfill, China

#

is for MSWs in Orchard Hills landfill, USA

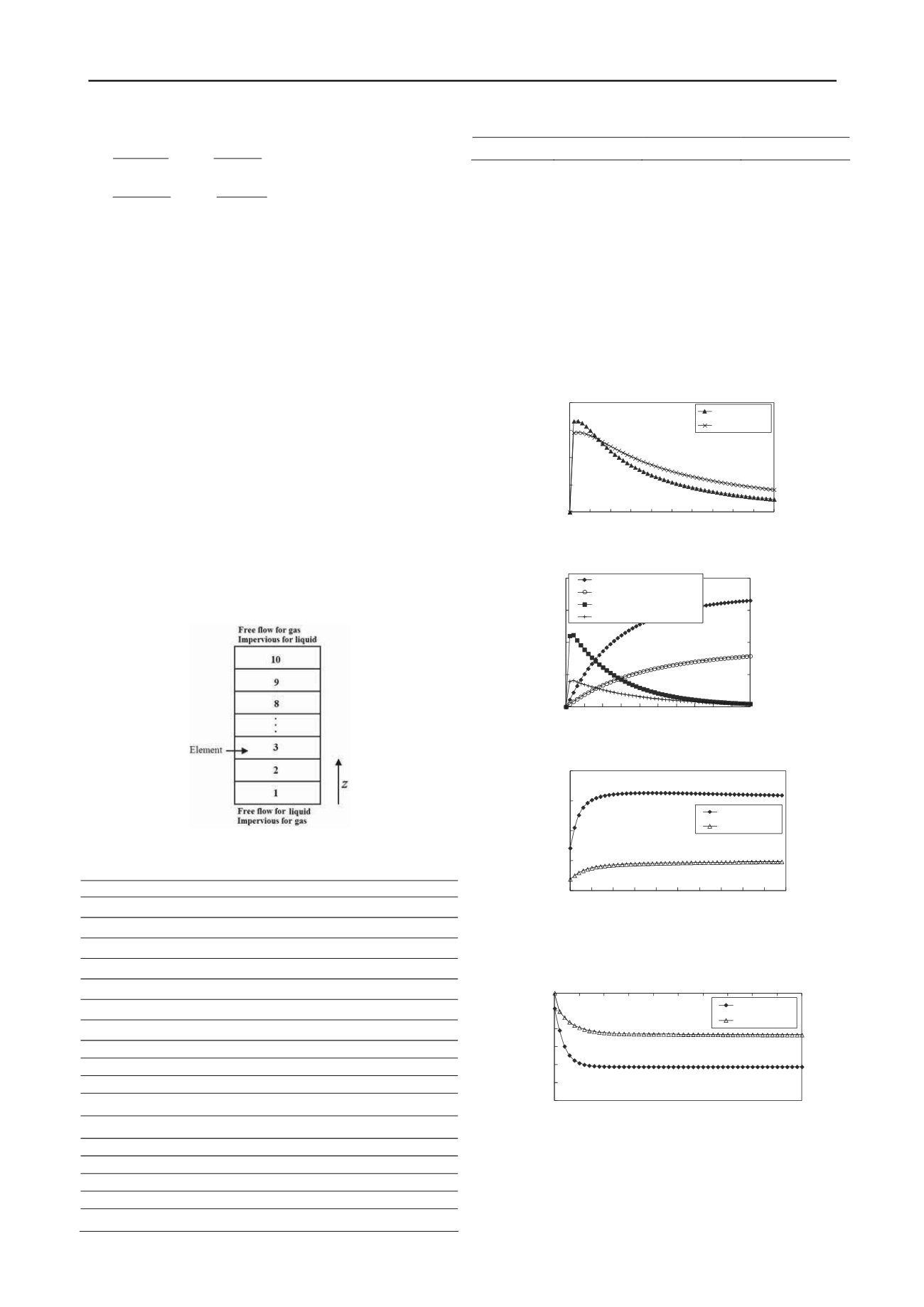

As shown in Table 2, waste sample from Qizishan landfill

has higher organic content (i.e.

m

ds

1

which represents highly

degradable component) and initial moisture content (i.e.

w

0

),

compared to that from Orchard Hills landfill. Two samples are

both assumed to have an optimum biodegradation condition (i.e.

f

water

=1.0). Simulation results are shown in Figure 5-8. It

indicates that gas pressure of waste sample from Qizishan

landfill have larger gas pressure during the early stage. Gas

generation rate, gas production, leachate production and surface

settlement of waste sample from Qizishan landfill are all much

greater than that from Orchard Hills landfill.

0

400

800

1200

1600

0 5 10 15 20 25 30 35 40 45 50

Gas pressure

at thebottom (Pa)

Time(year)

Qizishan

OrchardHills

Figure 5. Gas pressure at the bottom of waste samples

0.00

0.01

0.02

0.03

0.04

0.0

0.1

0.2

0.3

0.4

0 5 10 15 20 25 30 35 40 45 50

Gas generationrate

(m

3

kg

-1

year

-1

, dry basis)

Gas production

(m

3

kg

-1

, dry basis)

Time(year)

Left axis-Qizishan

Left axis-OrchardHills

Right axis-Qizishan

Right axis-Orchard Hills

Figure 6. Gas generation rate and gas production of waste samples

0

0.05

0.1

0.15

0.2

0 5 10 15 20 25 30 35 40 45 50

Leachateproduction(m

3

/m

3

)

Time(year)

Qizishan

OrchardHills

Figure 7. Leachate production per volume of waste samples

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0 5 10 15 20 25 30 35 40 45 50

Settlement(m)

Time(year)

Qizishan

OrchardHills

Figure 8. Settlement of waste samples