3007

Technical Committee 215 /

Comité technique 215

3.2 In situ tests

3.2.1 Comparison with laboratory tests

In-situ tests are an alternative to the execution of laboratory

tests on landfill samples. With in-situ tests there is no need to

take and manipulate samples, with the subsequent alteration,

very high when dealing with MSW. In-situ tests are made over

the material in real conditions, not in a simulated laboratory

scenario.

Besides, scale is larger in field tests, affecting more

material. This bigger scale reduces the influence of MSW

heterogeneity, making possible to take into consideration

medium to large fibrous elements. However, these advantages

over laboratory tests bring some additional problems:

Although the alteration produced by taking the sample is

removed, effects produced by the installation of the testing

elements appear.

Field tests control (stress state, displacements, drainage) is

lesser than in laboratory tests.

Even though the area affected by field tests is larger than the

regular specimen size, scale problems are still present.

Results obtained from some in-situ tests cannot be analysed

using theoretical models to obtain strength parameters, the

only way to obtain them are using empirical correlations.

Interpretation complexity is higher for in-situ tests in

comparison with those conducted in a laboratory. If the

theoretical model depends on two or more parameters, like

Mohr-Coulomb failure criterion, it is only possible to obtain

the relationship between them. This implies that only a

curve for different possible values for cohesion and

frictional angle can be obtained.

In any case, most of the in-situ test procedures are quite fast

and economical, making possible to execute multiple tests in a

reasonable period of time and covering a large volume of

material, which is a clear advantage over laboratory tests.

3.2.2 Test types

The in-situ tests commonly used in MSW are: penetration test,

plate loading tests, pressuremeter tests and in-situ shear tests.

Penetration tests, both dynamic (DPSH, DPH, SPT) and

static (CPT, CPTU) provide an index value for MSW strength,

and from these indexes it is possible to empirically obtain

strength parameters and other characteristics. Their main

advantages are their easy usage and their low time and means

consumption, as well as the possibility to check different

penetrations in time and space to establish tendencies for the

variation of the resistance to penetration.

Use of penetration test for landfill characterization is

frequent, being one of the pioneers Sowers (1968) who used

dynamic tests. The University of Cantabria (UC) Geotechnical

Group has researched about the strength characteristics of

landfills using dynamic and static penetration tests (Palma,

1995; Sánchez et al., 1993). In a recent research, Zhan et al.

(2008) used, among others, static penetrometers.

Furthermore, the interpretation of plate loading tests is not

as straightforward as in soils, due to the heterogeneity of the

landfill. It is advisable to use large diameter plates (>600 mm),

which is feasible because there is no need to apply large loads in

order to produce the needed deformations or even to reach

failure due to the soft nature of the MSW.

Several researchers have used this method for deformability

and strength characterization of MSW. The UC Geotechnical

Group (Palma, 1995; Sánchez et al, 1993) used load plates,

interpreting the results using a multi-layer model for MSW and

covering layers. In some occasions the rigid plate has been

replaced by a container full of material, achieving larger size

but lower pressure.

Pressuremeter tests, both with previous borehole execution

and using self-boring systems have been recently used in

landfills (Dixon et al., 2006).

There are several experiences with in-situ shear tests using

parallelepipedic and cylindrical samples with sizes of 500 mm

and even 1m in landfills (Withiam et al., 1995; Caicedo et al.,

2002).

3.3 Back-analysis of real failures

Failure back-analysis is a widely used method in geotechnical

activity and can be easily extrapolated to the study of MSW

shear strength (Huvaj-Sarihan and Stark, 2008).

However, this method faces also some uncertainties. First,

generalized failure cases are not frequent, and in the few cases

occurred it is difficult to detect the failure surface. Besides,

failure generally affects to the bottom sealing layers and the

foundation ground as well as to the waste mass itself. In other

cases the situation analysed is far from failure so a safety factor

greater than the unit has to be assumed with no precise

justification. Furthermore, the values for material density and

phreatic level position are not known exactly and must be

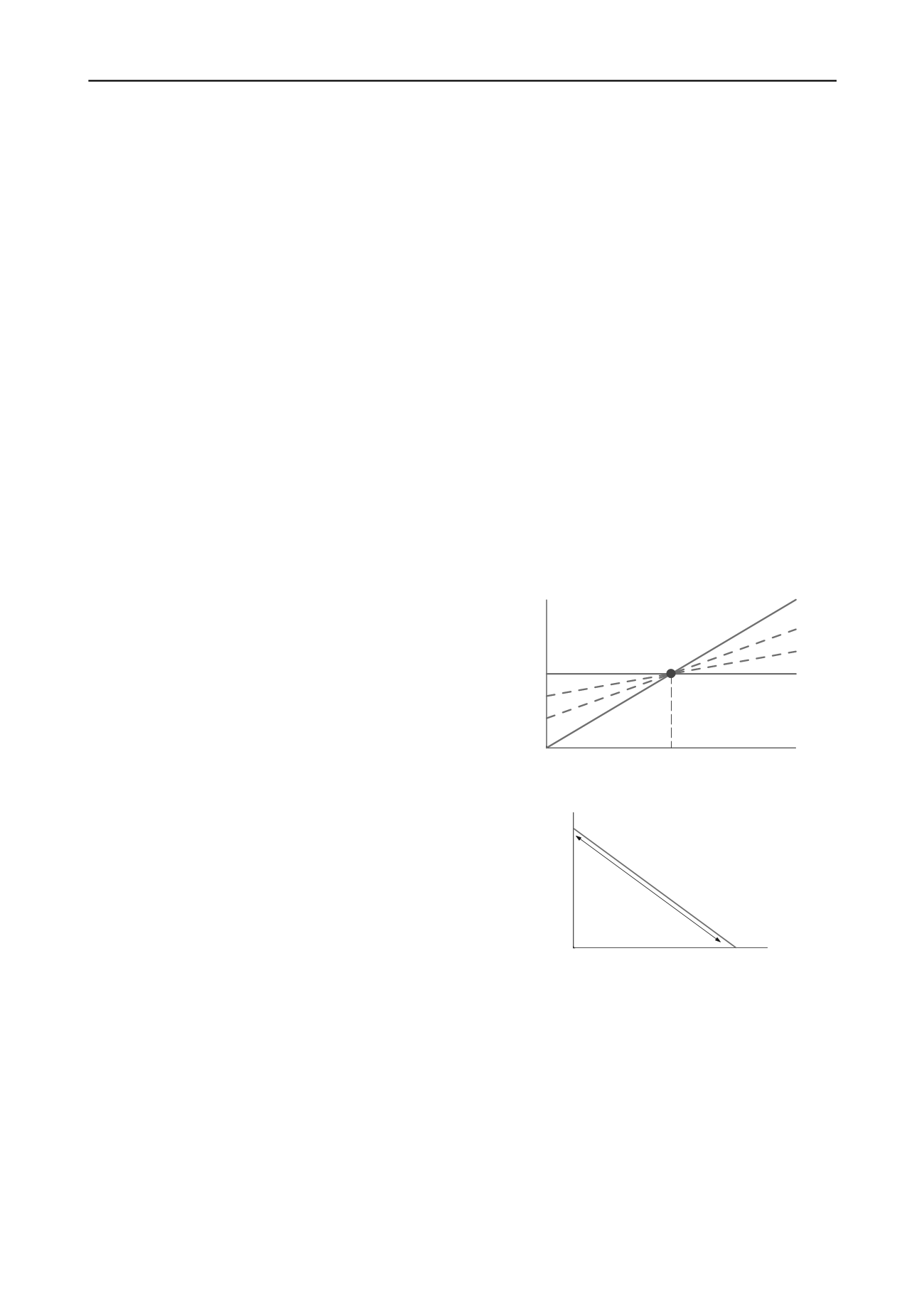

estimated. In any case, if the Mohr-Coulomb failure criterion is

used, the result of the analysis is only a relationship between

cohesion and frictional angle as in some in-situ tests. Only in

very few cases, the precise knowledge of the sliding surface

position can provide some guidance about the relative ranges

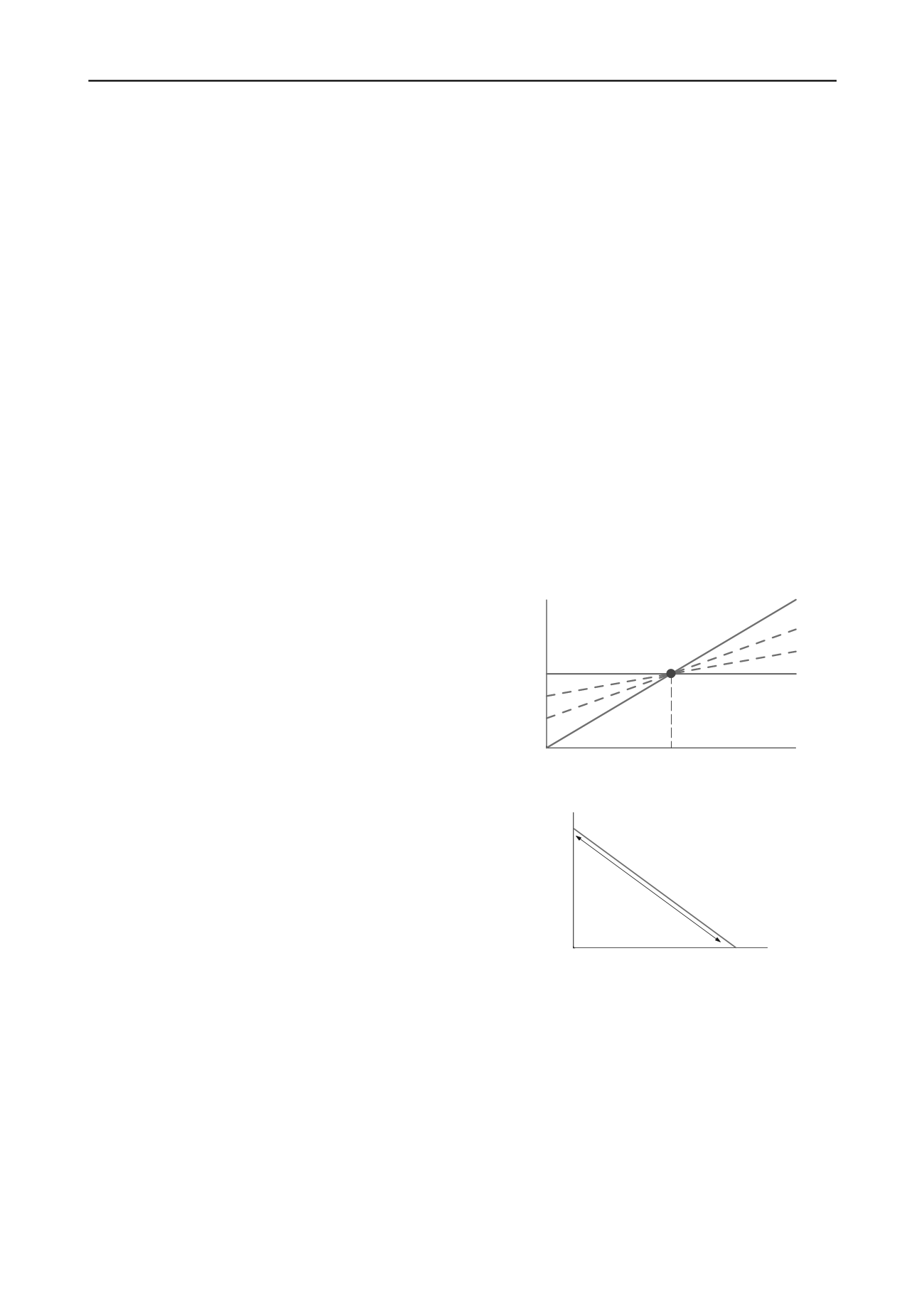

for the two parameters. Otherwise, the result is a line plotted in

a c-

diagram. This diagram must be used with care, because it

does not mean that all the points on the line are valid, but

instead, only one point is the correct result, but it is not possible

to identify it within the whole line (Figures 3 and 4).

av

'

av

tan

=

av

/

'

av

c = 0

= 0

c =

av

Normal effective stress,

'

Shear stress,

Figure 3. Mohr’s plane of the results of a back-analysis

?

Friction, tan

Cohesion,

c

Figure 4. c-

diagram of the results of a back-analysis

4 MOHR-COULOMB STRENGTH PARAMETERS

PROPOSAL

Although the research in strength parameters dates back more

than two decades, the special characteristics of MSW limit the

obtained results. In several publications a compilation of

parameter values is shown, but they do not only refer to test

results, it also does to representative values deduced by the

authors of other previous compilations and to values

successfully used in particular cases of landfill design. Besides,

the available results belong to different test type and

methodology, carried out on MSW of different composition,

age, density, etc. Furthermore, due to strain hardening

behaviour, different values can be established for the same test

according to the deformation level considered as critical.