2999

Technical Committee 215 /

Comité technique 215

3

RESULTS

3.1

Soil-Bentonite Vertical Cutoff Walls

Soil-bentonite (SB) cutoff walls are commonly constructed in

the US using the slurry trench method in which a trench is

excavated and filled with bentonite-water slurry (typically 4-6

% bentonite) to maintain trench stability, the trench spoils are

mixed with dry bentonite (as needed) and slurry to create a

homogeneous, high-slump SB backfill, and the backfill is

placed into the trench to create the wall. The slurry viscosity

must be sufficiently high to maintain trench stability, yet

sufficiently low to be easily displaced by the backfill. The slurry

also should form an adequate filter cake along the trench

sidewalls to minimize slurry loss during construction.

Recommended slurry properties include a Marsh viscosity of

32-40 s and a filtrate loss of < 25 mL (Evans 1993). Also, the

backfill must exhibit a low hydraulic conductivity, typically ≤

10

-9

m/s for geoenvironmental containment applications.

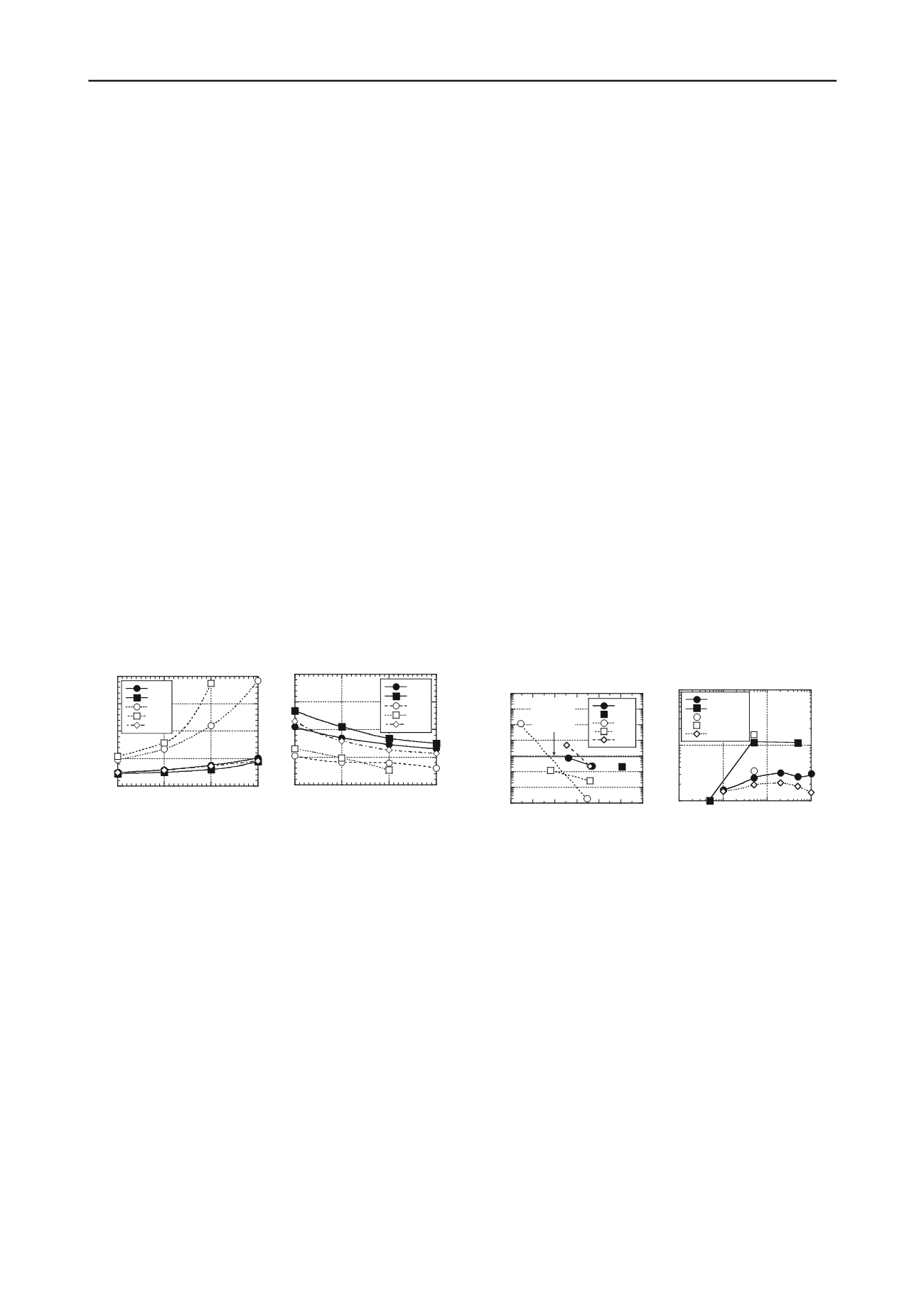

The influence of bentonite content on the Marsh viscosity

and filtrate loss (API 13A-B) of slurry containing untreated

bentonite (NB1, NB2) or treated bentonite (HC8, BPN, MSB) is

illustrated in Fig. 1. Slurries containing 3-5 % NB1, NB2, or

MSB exhibit viscosities within the range of 32-40 s (Fig. 1a).

For these clays, a bentonite content of 5 % likely would be

selected to obtain a greater slurry density and reduce filtrate loss

(Fig. 1b). In contrast, the viscosities of slurries containing ≥ 3

% HC8 or BPN were > 40 s and increased drastically with

increasing bentonite content due to thickening caused by the

polymer. Thus, slurry containing 2 % HC8 or BPN would be

appropriate for slurry trench construction based on viscosity.

Finally, the filtrate losses for 2 % HC8 and BPN are equal to or

lower than the filtrate losses for 5 % MSB or NB1.

20

40

60

80

100

2

3

4

5

(a)

0

10

20

30

40

2

3

4

NB1

NB2

BPN

HC8

MSB

Marsh Viscosity (s)

Bentonite Content (%)

5

(b)

NB1

NB2

BPN

HC8

MSB

Filtrate Loss (mL)

Bentonite Content (%)

Figure 1. Properties of bentonite-water slurries as a function of

bentonite content: (a) Marsh viscosity; (b) filtrate loss (NB1 and MSB

data from Malusis et al. 2010; NB2 and BPN data from Bohnhoff 2012).

Hydraulic conductivity and chemical compatibility of

model SB backfills comprised of sand and NB1, NB2, MSB, or

BPN were investigated in recent studies by Malusis and

McKeehan (2012) and Bohnhoff (2012). Although the sands

used in both studies were clean and poorly graded, the sand

used by Malusis and McKeehan (2012) in the NB1 and MSB

backfills was a fine sand (

D

50

= 0.20 mm) whereas the sand

used by Bohnhoff (2012) in the NB2 and BPN backfills was a

medium sand (

D

50

= 0.45 mm). In both studies, the specimens

were tested in flexible-wall cells at low confining stresses (≤

34.5 kPa). The specimens were permeated with tap water until a

steady

k

w

was achieved, and then were permeated with CaCl

2

solutions (5-1,000 mM) until termination criteria for chemical

equilibrium between the influent and effluent were achieved

(see cited references for further details).

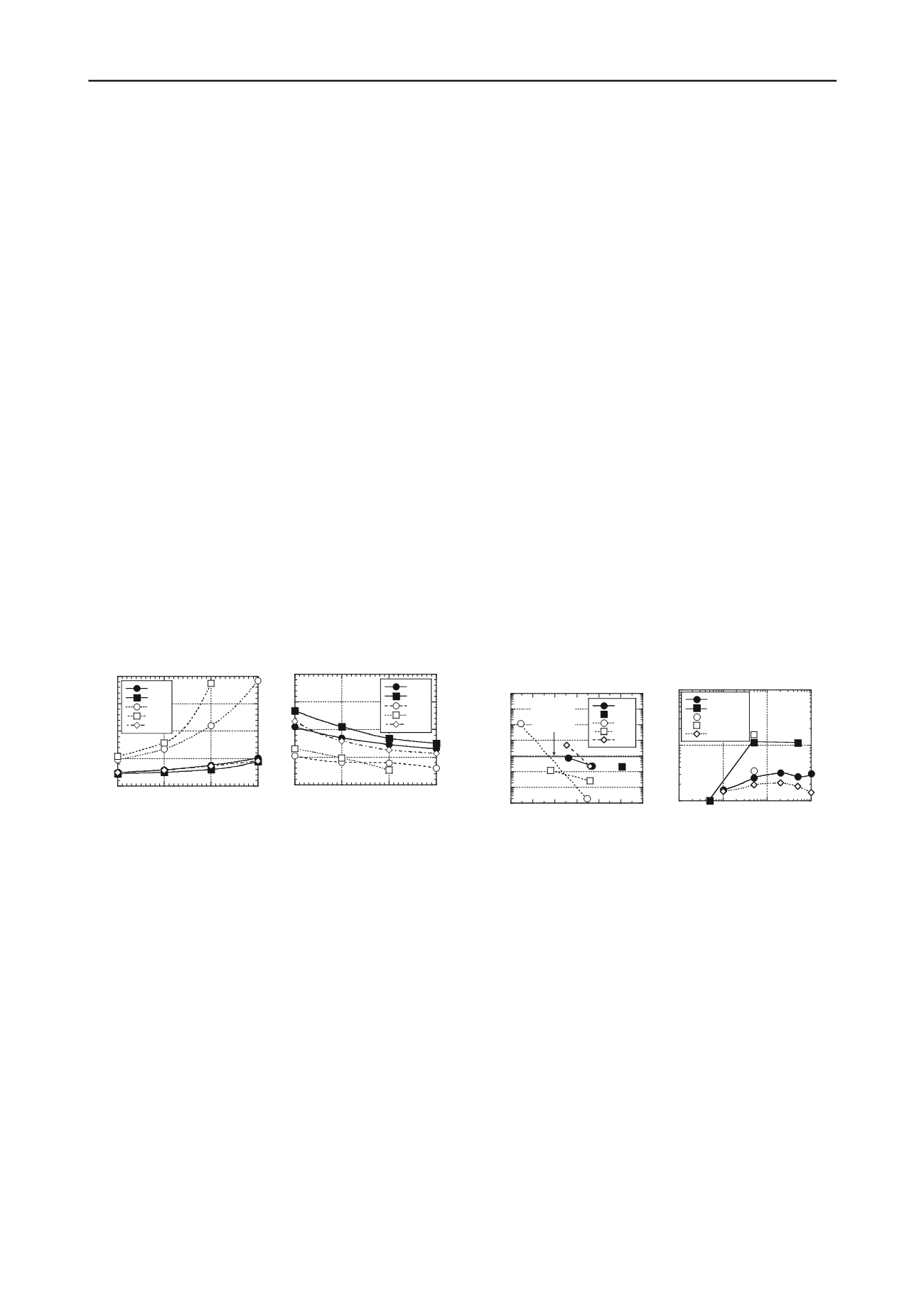

The measured

k

w

values from these studies are presented in

Fig. 2a along with

k

w

values measured recently at Bucknell

University for sand-bentonite backfill specimens containing

HC8 and the same fine sand used by Malusis and McKeehan

(2012). The backfills containing the polymer-modified

bentonites (BPN or HC8) generally exhibited lower

k

w

relative

to the backfills containing similar percentages of MSB or Na-

bentonite (NB1 or NB2), indicating that less BPN or HC8 is

needed to create backfill with an acceptable

k

w

(i.e., ≤ 10

-9

m/s).

The influence of CaCl

2

on the

k

of backfill specimens

containing 5.7 % NB1 or 5.6 % MSB (Malusis and McKeehan

2012) and specimens containing 7.1 % NB2, 2.4 % BPN, and

5.5 % BPN (Bohnhoff 2012) is shown in Fig. 2b. All of the

specimens were susceptible to an increase in

k

, i.e.,

k

c

/

k

w

> 1,

where

k

c

= hydraulic conductivity to the CaCl

2

solution, when

permeated with ≥ 10 mM CaCl

2

solutions. The increases varied

from approximately two-fold to 15-fold depending, in part, on

the bentonite content. For example, the specimen containing

the most bentonite (7.1 % NB2) exhibited the highest

k

c

/

k

w

(~15) of all the specimens. Also, the 2.4 % BPN specimen

exhibited a lower

k

c

/

k

w

relative to the 5.5 % BPN specimen

permeated with the same CaCl

2

solution (50 mM). However,

k

w

for the 5.5 % BPN backfill (2 x 10

-12

m/s) was well below the

typical regulatory limit (10

-9

m/s), whereas

k

w

for the 2.4 %

BPN backfill was unacceptably high (10

-7

m/s; see Fig. 2a).

Thus, the lower BPN content (2.4 %) was advantageous in

terms of chemical compatibility, but was insufficient for

achieving regulatory compliance in terms of

k

.

For the specimens with similar bentonite contents (i.e., 5.7

% NB1, 5.6 % MSB, and 5.5 % BPN), the 5.6 % MSB

specimens exhibited the greatest resilience. The higher values of

k

c

/

k

w

for the 5.5 % BPN specimens relative to 5.6 % MSB and

5.7 % NB1 specimens permeated with the same CaCl

2

solution

were attributed to two primary factors, viz., the greater

reactivity of the 5.5 % BPN specimens, as reflected by the

lower

k

w

for this backfill relative to those containing 5.6 %

MSB or 5.7 % NB1 (see Fig. 2a), and the use of a coarser (i.e.,

more permeable) sand in the BPN backfills relative to the MSB

and NB1 backfills. However, the lower

k

w

for the 5.5 % BPN

backfill also allowed for a greater increase in

k

to occur without

exceeding the typical regulatory limit of 10

-9

m/s.

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

2 3 4 5 6 7 8

(a)

NB1

NB2

BPN

HC8

MSB

Hydraulic Conductivity,

k

w

(m/s)

Bentonite Content (%)

Typical

Regulatory

Limit

1

10

100

1

10

100

1000

(b)

5.7 % NB1

7.1 % NB2

2.4 % BPN

5.5 % BPN

5.6 % MSB

k

c

/

k

w

CaCl

2

Concentration (mM)

Figure 2. Permeation results for sand-bentonite backfills: (a) hydraulic

conductivity to water,

k

w

, as a function of bentonite content; (b) ratio of

hydraulic conductivity to CaCl

2

solution,

k

c

, relative to

k

w

as a function

of CaCl

2

concentration (NB1 and MSB data from Malusis and

McKeehan 2012; NB2 and BPN data from Bohnhoff 2012).

3.2

Geosynthetic Clay Liners (GCLs)

Values of

k

c

for BPN, HC2, and MSB specimens representing a

typical GCL are shown in Fig. 3a. Data for specimens of Na-

bentonite taken from actual GCLs (Bentomat

®

DN, CETCO,

USA) are included in Fig. 3a for comparison. All specimens

were permeated in flexible-wall cells under low effective

stresses (14 to 30 kPa) until the hydraulic termination criteria of

ASTM D 5084 were satisfied. Also, most of the specimens were

permeated until chemical equilibrium (defined as the ratio of

outflow and inflow electrical conductivity within 1.0 ± 0.1) was

achieved, with the exceptions being the specimens permeated

with deionized water (DIW) and the HC2 specimens. The

results reflect a "worst-case" testing condition in that the

specimens were not prehydrated prior to permeation

(Shackelford et al. 2000). Permeation with DIW (plotted at 0.1

mM CaCl

2

in Fig. 3a) resulted in low

k

w

(i.e., 4.2 x 10

-12

to 3.4 x

10

-11

m/s) regardless of the bentonite type. However, the BPN,

HC2, and MSB exhibited superior hydraulic behavior (i.e.,

lower

k

c

) relative to the GCL bentonites. These results illustrate

the potential advantage of novel bentonites in solutions typically