2992

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

bentonite content. The authors indicated that the differences in

behaviour among these novel bentonites illustrated in this paper

highlight the need for further research into the specific

mechanisms affecting the performance of such new materials.

At the same time, the paper shows the potential that such

bentonites can have in addressing aggressive solutes.

10

-13

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

0.1

1

10

100 1000

(a)

GCL

BPN

HC2

MSB

Hydraulic Conductivity,

k

w

or

k

c

(m/s)

CaCl

2

Concentration (mM)

1

10

100

1

10

100

1000

(b)

5.7 % NB1

7.1 % NB2

2.4 % BPN

5.5 % BPN

5.6 % MSB

k

c

/

k

w

CaCl

2

Concentration (mM)

10

m

Brianzoni et al

. report the results of a research study aimed

at evaluating and predicting the long term hydraulic

performance of cement bentonite (CB) mixtures used in cut off

walls when in contact with saline solutions (K

2

SO

4

) or acidic

solutions (H

2

SO

4

) at different concentrations. Hydraulic

conductivity tests were conducted for this purpose and lasted in

some cases for 2 year to assess the CB mixtures chemical

compatibility. This paper shows that the saline and acidic

solutions can adversely affect the hydraulic performance of CB

mixtures depending on SO

4

2-

concentration and pH. At

concentration of the order of 25 g/l or more, both solutions

produced an initial decrease in the k value, followed by an

increase and finally an almost constant trend of hydraulic

conductivity with curing time. Swelling and a dense net of

fixtures were detected on both samples after permeation due to

ettringite formation. Sample thickness was found to affect the

response of the CB mixtures when permeated with saline

solutions. The authors indicated that the chemical conditions

adopted in the tests are not expected to occur continuously in

the field if a pumping system is provided so that there is an

advective flow of groundwater and not of pollutant across the

barrier.

Indrawan et al.

present the findings of the work they have

conducted on the effects on the hydraulic conductivity of

compacted clays, commonly used for lining coal seam gas

(CSG) water storage ponds, of moisture conditioning and

permeation with CSG water. Four kaolinite-dominant clays

were mixed with CSG and deionised waters and compacted to

varying compaction degrees at different gravimetric moisture

contents before permeation. Tests were conducted in a rigid

wall permeameter (100 kPa hydraulic loading) and in an

oedometer (100 kPa axial stress). The hydraulic conductivity of

clays moisture-conditioned, compacted and permeated with

saline CSG water (k= 1x10

-11

m/s) was found to be similar to

that of the same clays moisture-conditioned, compacted and

permeated with deionised water. In both CSG and deionised

waters, the compacted clay particles dispersed and the hydraulic

conductivity decreased to a very low value of about 1x10

-11

m/s.

The hydraulic conductivities measured using a compaction

mould permeameter were found to be comparable to, and a little

higher than, those calculated from oedometer test data for the

same compacted clays. The authors concluded that the clays

investigated would be suitable as a liner for a CSG water

storage pond.

Hanson et al.

present the results of a laboratory investigation

aimed at determining the moisture-suction relationships of

geosynthetic clay liners (GCLs) under as-received conditions

(moisture contents in the range of 14-27%) and subsequent to

wet-dry cycles (20 cycles at 50% moisture content). Tests were

conducted on three types of needle punched GCLs which

contained granular bentonite. Two of the GCLs were of the

conventional types whereas the third GCL was of a multi-

component type (i.e. the carrier geotextile was composed of a

non woven geotextile and a geofilm). Differences were

observed between the conventional and multi-component GCLs

and between the as-received and wet-dry cycled GCLs. The air

entry suction value for the multi-component GCL was found to

be lower than that for the conventional GCLs for the drying

branches of the moisture suction curves and higher for the

wetting branches of the curves. The residual suction value for

the multi-component GCL was found to be higher than the

residual suction values for the other two GCLs. The extent of

hysteresis decreased and the differences between drying and

wetting curves reduced for the wet-dry cycled specimens

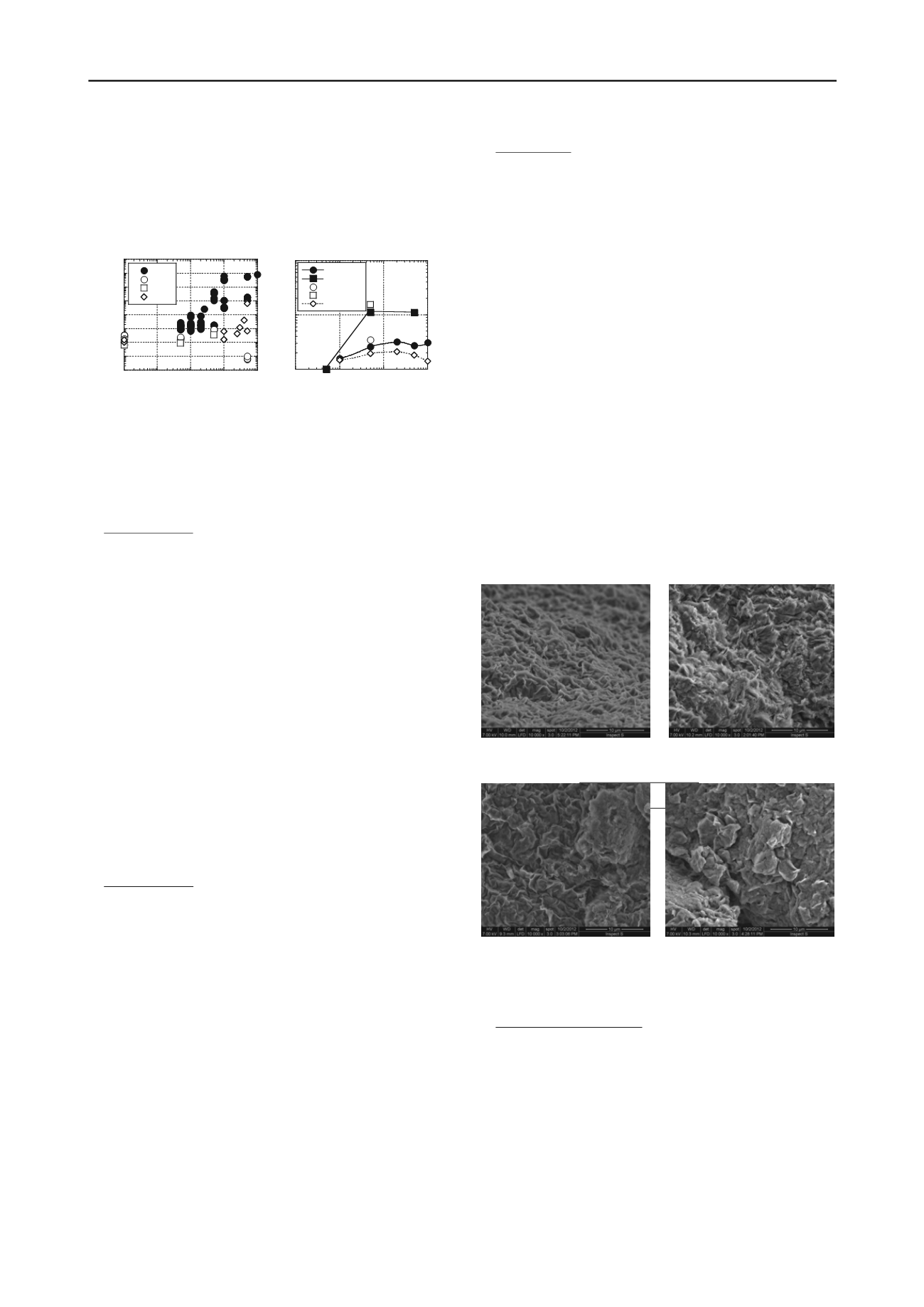

compared to the as-received specimens. Macro- and micro-

structural variations determined through grain size distribution

and SEM analyses (Fig. 3) indicated increasing void sizes and

non-uniformity in fabric due to wet-dry cycling, supporting the

observations made for variations in moisture-suction response.

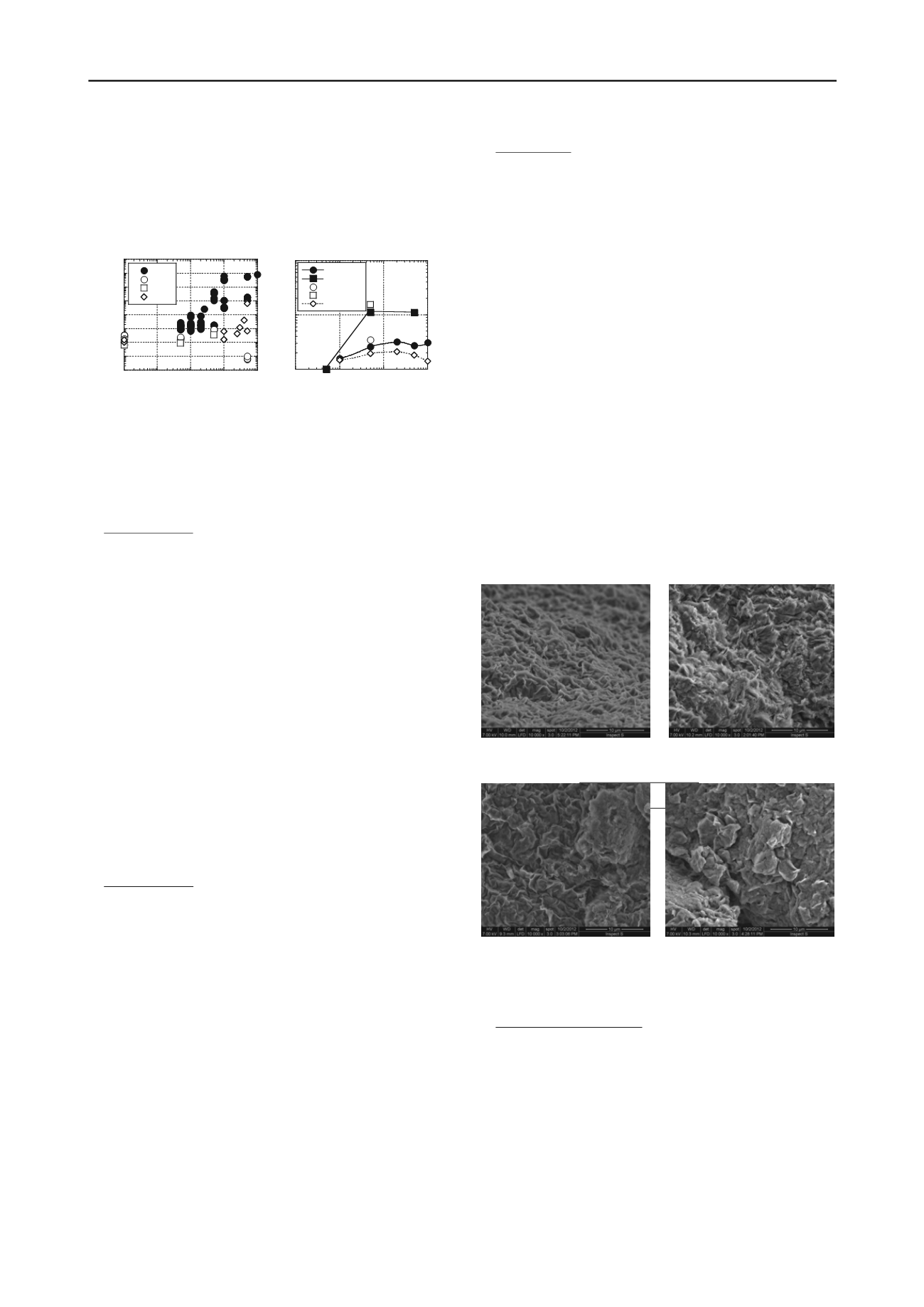

Figure 2. Permeation results for

sand-bentonite backfills: ratio of

hydraulic conductivity to CaCl

2

solution,

k

c

, relative to hydraulic

conductivity to water

k

w

as a

function

of

CaCl

2

concentration

(Bohnhoff et al., 2013)

Figure 1 Hydraulic conductivity

of bentonite specimens as a

function

of

(a)

CaCl

2

concentration in the permeant

liquid (Bohnhoff et all., 2013)

a) 1 cycle (fully dispersed) b) 10 cycles

c) 20 cycles (DI water) d) 20 cycles (tap water)

Figure 3. SEM images of bentonite from GCL specimens (Hanson et al.

2013)

Rayhani and Sarabadani

describe a laboratory simulation

study undertaken to quantify the hydration progress of

Geosynthetic Clay Liners (GCLs) from underlying subsoils

under simulated landfill conditions, before and after having

been covered by municipal solid waste. GCL hydration was

shown to be highly dependent on GCL manufacturing

techniques, grain size distribution and initial moisture content of

the subsoil. In particular, the difference in suctions between the

GCLs and the type of subsoils was found to be an important

factor governing the hydration process. The thermally treated,

scrim-reinforced GCL demonstrated higher rate and degree of

hydration compared to the other GCL products tested under

similar conditions mainly due to the better anchorage of the

connection layer against swelling of bentonite upon hydration.