3006

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The shear stress-strain curve of the MSW shows a

noticeable hardening (Grisola et al., 1996; Jessberger et al.,

1993; Eid, 2000; Zhan et al., 2008), and a horizontal

asymptotic level is not reached even with large

deformations. So it is necessary to define a certain level of

deformation in which it is assumed that the failure situation

is being reached.

3 METHODS FOR OBTAINING MSW STRENGTH

The methods for obtaining cohesion and frictional angle

parameters can be grouped in three kinds: laboratory test, in-situ

test and back-analysis of actual failures.

3.1 Laboratory tests

3.1.1 Sample conditions

Although laboratory tests are the most direct method for

obtaining the strength parameters of a material, they show

several problems that make difficult both their usage and the

subsequent interpretation when working with MSW.

The first problem is to find representative samples. Samples

obtained in the same landfill show a large dispersion in

composition due to the heterogeneity of the waste mass. Some

research has been done on “synthetic” samples, reconstituted

with the average composition of the MSW mass in the landfill

region or country (Sivakumar Babu et al., 2010).

On the other hand, among the MSW there are elements with

a medium to large size. So it is necessary to take large samples,

this is quite easy for MSW that have just arrived to the landfill,

or for recently disposed and superficial waste, but makes it

necessary to bore large diameter bore-holes (over 760 mm in

diameter) (Bray et al., 2009) for deep waste.

It is very hard to take undisturbed samples from MSW,

particularly at great depth. Densification is produced during the

sampling process due to the large deformability of MSW.

Because of the low cohesion, the loose nature of the material

and the differences in size and stiffness among the different

constitutive elements, alterations and collapses are produced

during the sampling and trimming operations.

For these reasons, tests are made using samples prepared

and compacted to in-situ density and moisture content, and with

the prevailing composition. The uncertainties associated to these

conditions make that this procedure can be only considered as

an approximation of actual landfill conditions. Besides, the

elements with a size over 1/5-1/10 of the minimum size of the

specimen to test, usually fibrous materials such as paper, plastic,

wood or metallic pieces, have to be removed or cut to fit this

size in order to not interfering with the movement of the test

equipment invalidating the results obtained. Furthermore, the

tensile strength of fibrous elements introduces an anisotropic

behaviour, making the strength obtained in the test depend on

the preferred direction of the fibres (Bray et al., 2009).

3.1.2 Test types

The tests used to obtain strength parameters are direct shear,

triaxial and simple shear tests.

From 23 research works revised by Stark et al. (2009), dated

from 1990 to 2005, 48% used laboratory direct shear tests, 22%

triaxial tests, and just one simple shear tests. The rest of them

are in-situ direct shear tests. Recently, Bray et al. (2009) have

presented the results of simple shear tests on 400x300 mm

rectangular samples.

In general test specimens have a relative large size. It is

frequent for the direct shear test probes to have a length of 300

millimetres or more and using triaxial specimens with over

200mm in diameter. Besides, the test equipment has to be

prepared to provide large deformations. This circumstance is

stated on plenty of the revised researches, and makes it

necessary to modify the original design of the equipment.

3.1.3 Other aspects

In tests on MSW samples, the applied shear stress increases

monotonically with deformation, and in most cases a maximum

or asymptotical value is not reached even with the application of

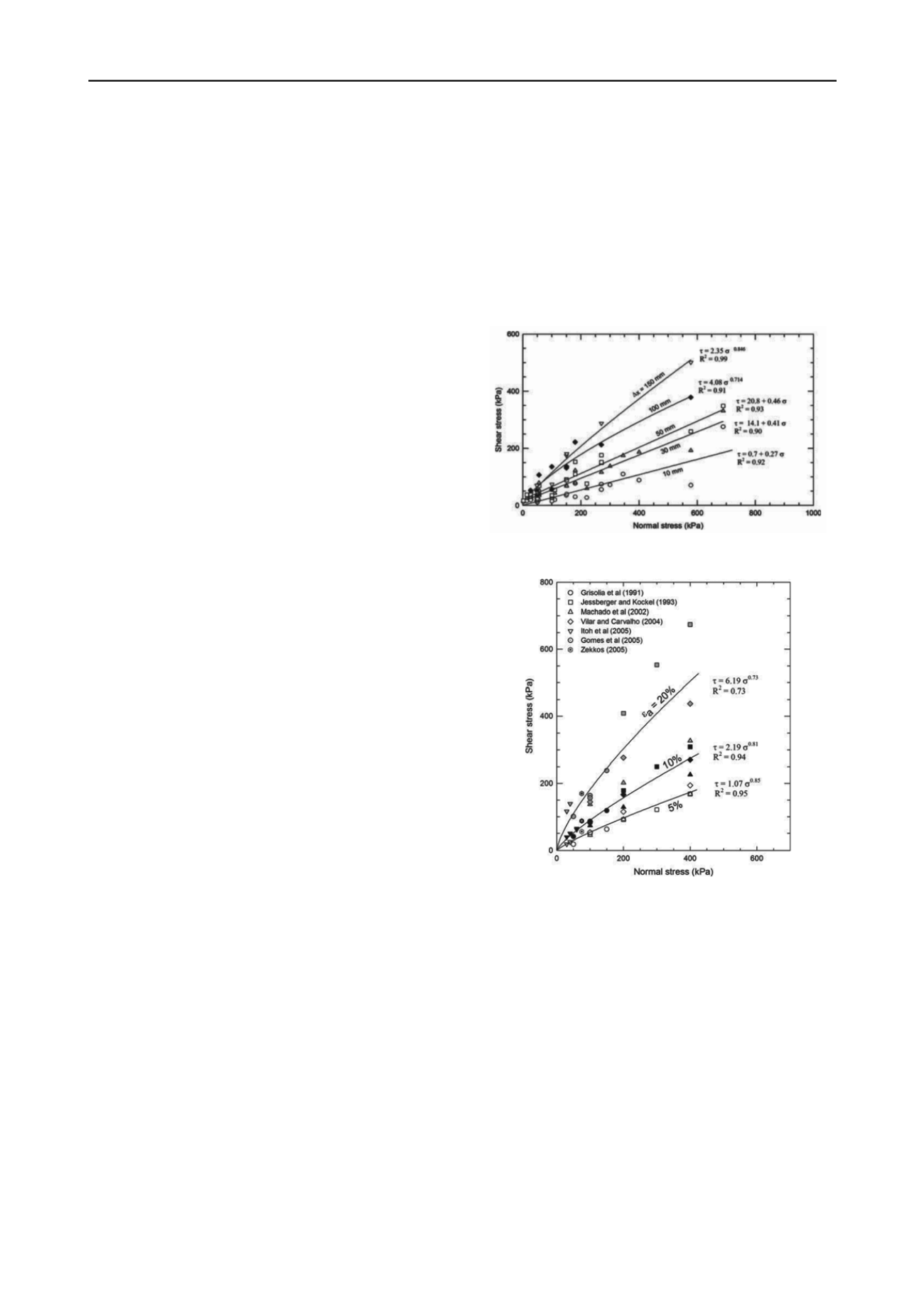

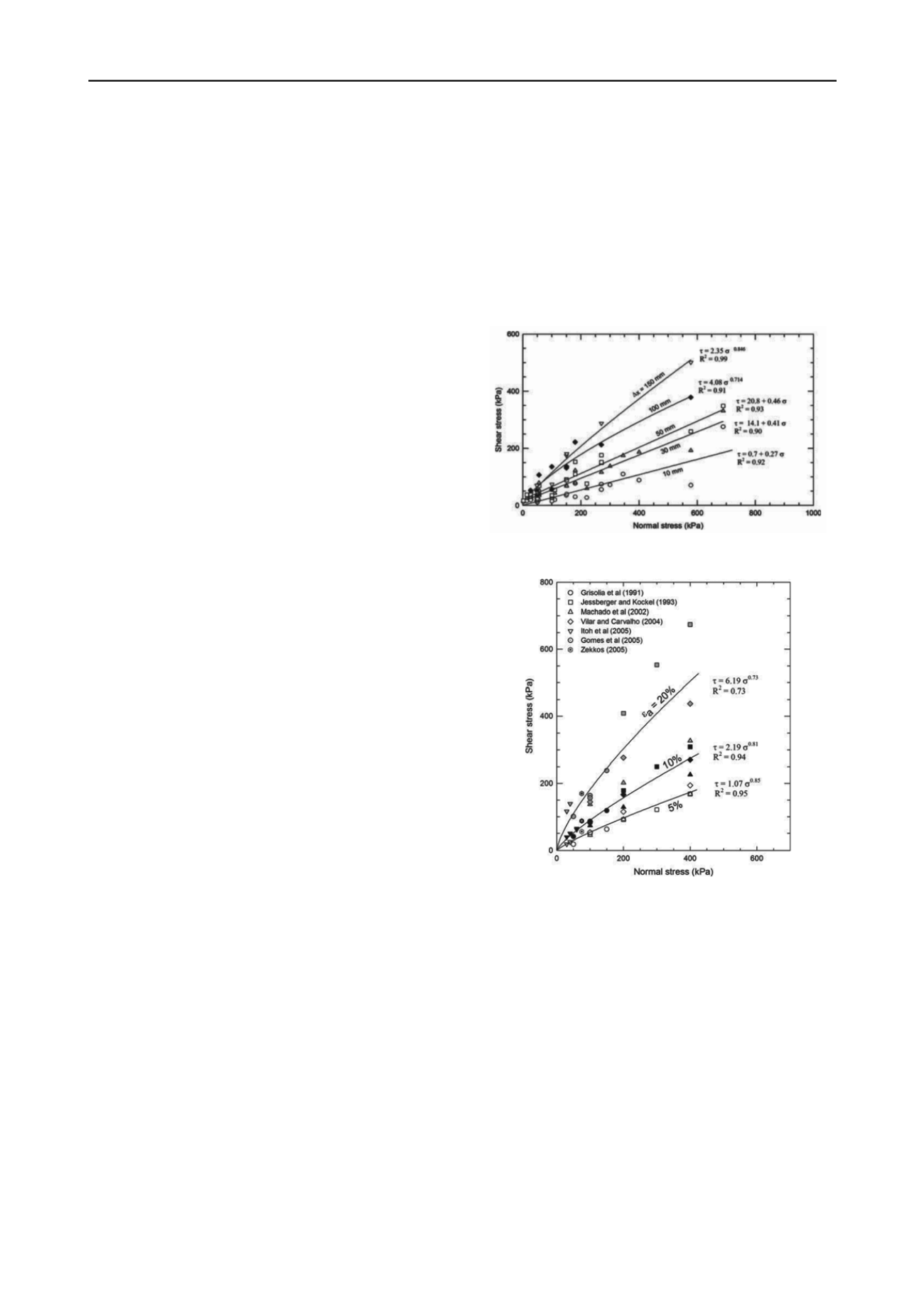

large displacements. The plots shown in Figures 1 and 2 belong

to a compilation of results from several authors made by Stark

et al. (2009). It is shown that shear stress does not grow only

with the applied normal stress, but it also increases with the

deformation or the displacement reached. Those authors

attribute this behaviour to the reinforcement action of the

wastes’ fibrous elements when deformation increases.

Figure 1. Summary of direct shear lab tests (Stark et al., 2009)

Figure 2. Summary of triaxial lab tests (Stark et al., 2009)

It has to be taken into consideration that in regular landfill

operation the possible deformation is much smaller than during

a test. Movement compatibility between MSW and the more

rigid sealing layers, and also with the deformation limit of

draining elements, gas evacuation elements, etc., limits waste

deformation to acceptable levels, forcing the definition of

strength parameters to an imposed deformation value (Machado

et al., 2002).

The environmental conditions where the laboratory tests are

conducted are problematic because of the odour and the

hazardous sample management, making necessary to fit out a

specific area, isolated from the rest of the laboratory. In some

research it is necessary to carry out most of the tests in facilities

belonging to the landfill grounds.

The difficulty in obtaining truly representative samples and

test environmental conditions affects negatively to the

possibility to undertake systematic shear strength laboratory test

campaigns. The revised bibliography shows that there are a

scarce number of tests executed for the amount of means

mobilized (Bray et al., 2009, Sivakumar Babu et al., 2010).