2797

Technical Committee 212 /

Comité technique 212

rock socket of both test piles consisted of slightly weathered,

medium to high strength, Triassic aged sedimentary rock

(interbedded layers of mudstone, sandstone and siltstone).

In both TP1 and TP2 the shaft resistance of the section of

rock socket existing between the level of the installed Osterberg

Cell and pile tip was observed to have become fully mobilised

during the application of a peak load (up to 56.6MN,

approximately 3.1 times the expected SLS load).

The maximum shaft capacity of the 2.66m length of shaft

that existed below the installed Osterberg Cell of TP1 was

calculated to be 17.55MN, with a residual value of 16.4MN.

The residual value represented a 7% decrease from the

maximum observed value. Similarly, the peak shaft capacity of

the 5.24m length of TP2 between the Osterberg Cell and pile tip

was determined to be 29.2MN.

3 ROCK SOCKET DESIGN PROCEDURES

Early work for rock socket design occurred in Australia by

Williams, Johnston and Donald (1980) who examined non-

linear pile design in Melbourne Mudstones, and Rowe and Pells

(1980) who calibrated elastic pile design with Sydney

Sandstones and Shales. Horvath and Kenny (1979) undertook

similar field and laboratory testing on mudstones in Canada

while Meigh and Wolshi (1979) conducted comparable work in

Europe. Side slip design was subsequently detailed by Rowe

and Armitage (1987).

Kulhawy and Phoon (1993) showed the discontinuity in shaft

friction between clays and various soft rocks (shales, mudstones

and limestone). Seidel and Haberfield (1995) extended that

work to demonstrate that rock socket performance is highly

dependent on shaft roughness and socket diameter; whereby pile

shaft friction reduces as the pile diameter increases.

Generally, rock socket design is governed by serviceability

conditions rather than ultimate load conditions, and the load –

deformation behaviour of the rock sockets are determined

largely by the rockmass deformation properties. The rockmass

modulus (

Ε

m

) value can be estimated from the modulus of intact

rock (

Ε

i

) reduced for the frequency of rock defects. Relevant

theory is discussed by Zhang (2004).

Various pile rock socket design procedures are now available

which frequently calculate the design shaft capacity based on

correlation with a “characteristic” compressive rock strength

(

q

uc

) value. A good summary of the shaft shear capacity

equations derived by design method researcher is provided in

Kulhawy et al. (2005). Gannon et al. (1999) described four of

these methods and showed, even when adopting consistent rock

properties for design, the resulting design pile socket shear

capacities ranged widely. The longest pile socket lengths for the

example provided were predicted by the Carter and Kulhawy

(1988) design method, while the Rowe and Armitage (1987)

and Williams et al. (1980) procedures reduced the socket

lengths by 40-60%.

This paper aimed to provide guidance on two key questions:

o

Which rock socket design method should be used?

o

What characteristic rock strength value should be selected

(and does the selected method alter the required value)?

Ng et al. (2001) showed that the correlations presented by

Rowe and Armitage (1987) and Hovarth et al. (1983) are

applicable for sedimentary and volcanic rocks respectively.

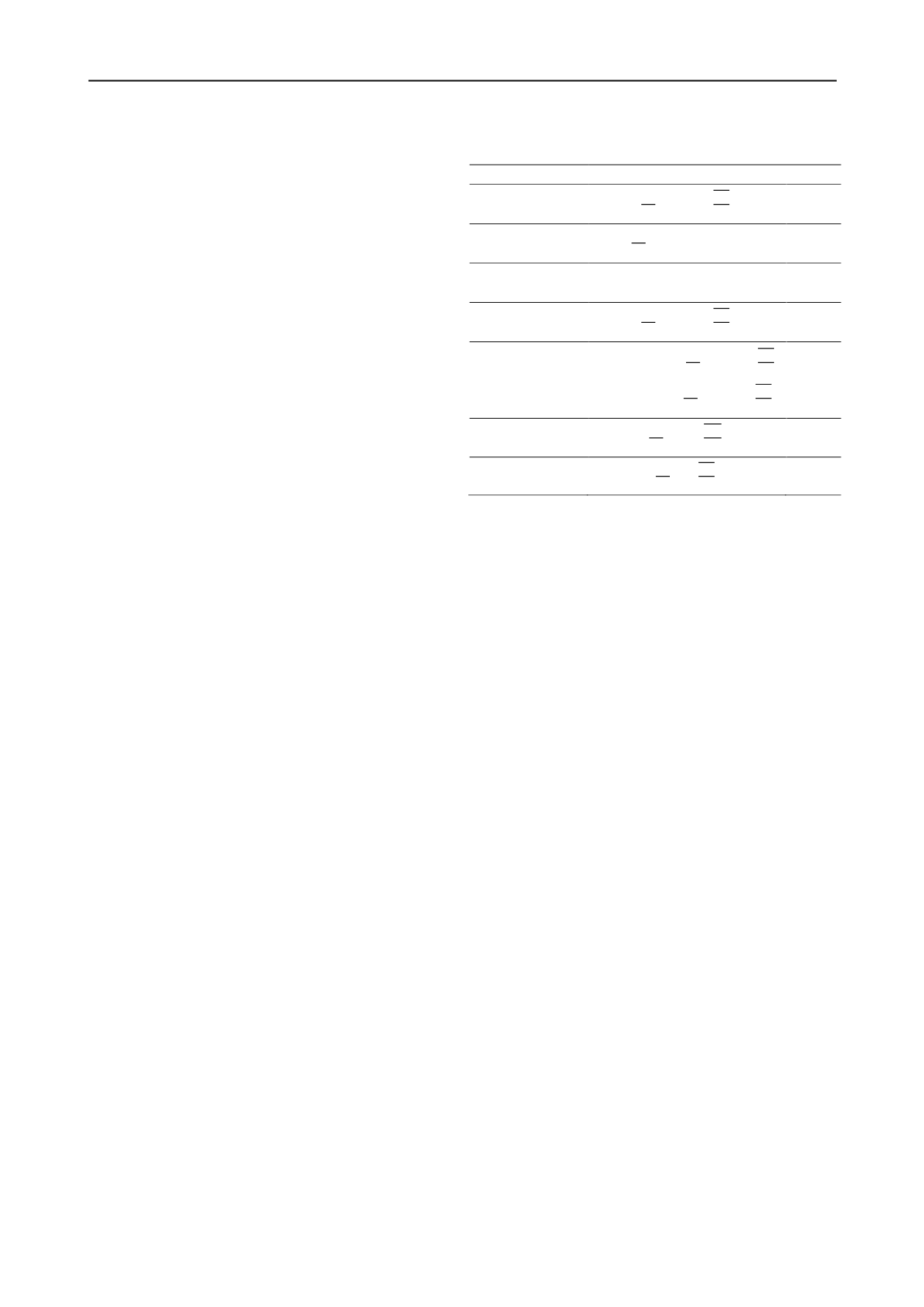

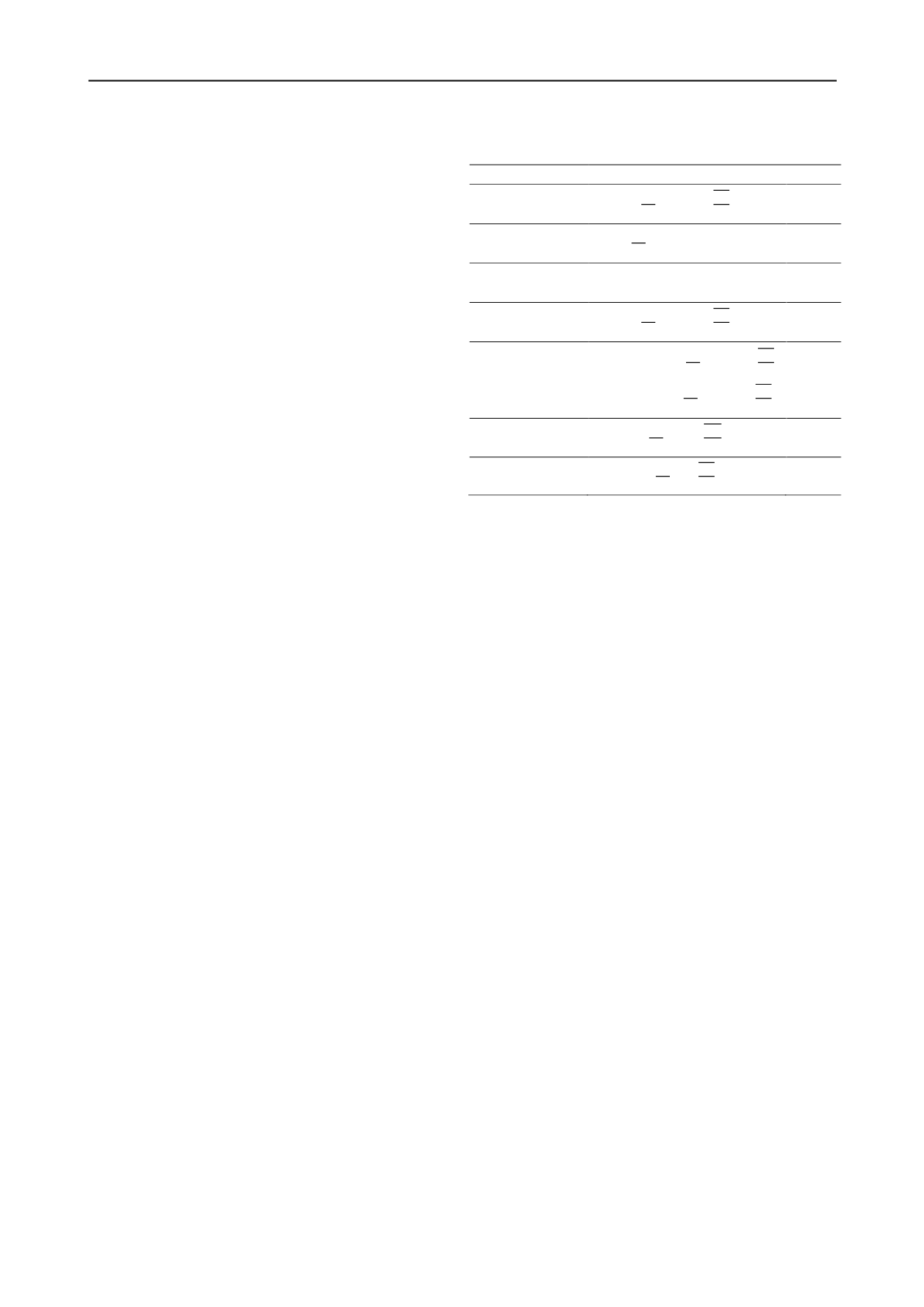

Table 3. Unit side resistance formulas for considered rock socket pile

design methodologies, normalised with atmospheric pressure (

)

Design Method

Normalised Unit Side Resistance Equation

Hovarth and Kenny

(1979)

*

= 0.65

(1)

Meigh and Wolski

(1979)

= 0.55(

)

.

(2)

Williams, Johnson

and Donald (1980)

= α(

)

(3)

Rowe and Armitage

(1987)

= 1.42

(4)

Carter and Kulhawy

(1988)

Lower Bound:

= 0.63

Upper Bound:

= 1.42

(5)

(6)

Kulhawy and Phoon

(1993)

=

(7)

Prakoso (2002)

=

(8)

*

Also confirmed by Zhang (1999) and Reese and O’Neill (1988)

3.1

Back-analysis of rock socket design methodologies

By using the measured ultimate shaft frictional capacity as the

basis for back-analysis, “characteristic”

q

uc

input values could

be determined for each considered rock socket design method.

Table 3 details the rock socket pile design methodologies

considered and the published formulae used in each to calculate

dimensionless unit side resistance values (

)

. These values are

transformed to rock socket design capacities via multiplication

of the calculated

value by the surface area of the segment of

the rock socket that was loaded to capacity. In this study it has

been assumed that the pile socket is effectively smooth and that

concrete strength does not limit the shear capacity of the pile.

No factors of safety have been applied as field data is being

fitted back to design equations.

Notes relevant to the formulae presented in Table 3 include:

o

Eq. (3) calculates shear capacity based on both the rock

strength value and a mass factor (

j

) which is defined as the

ratio of rock mass modulus to intact rock modulus. Based

on the average logged RQD values (TP1 = 70%; TP2 =

55%), a mass factor (

j

) of 0.33 would be appropriate for

TP1 (

j

= 0.20 for TP2). Also, in Eq. (3)

α

is directly related

to the adopted

q

uc

, whilst

β

is estimated from the

j

value.

o

Shaft capacity values for Eq. (4) are recommended to be

multiplied by a partial factor of 0.7 to ensure the probability

of exceeding design settlements is lower than 30%.

o

The coefficient C in Eq. (7) is based on conservatism and

rock socket roughness; C = 1 provides a lower bound

estimate, C = 2 for mean pile behaviour and C = 3 for upper

bound estimates or for rough rock sockets.

o

The approach used to derive Eq. (8) was cited by Kulhawy

et al. (2005) as providing the most consistent approach in

evaluation of the constructed pile load dataset.

3.2

Back-calculation Results

Table 4 provides a summary of the various input UCS values

required to achieve the ultimate shaft capacity values observed

in each test pile. These values have been back-calulated via use

of the equations detailed in Table 3. The 5

th

percentile closest to

the required UCS value has been determined for both the

normal and non-normal distribution functions fitted to each test

pile’s strength data (refer Table 2).