2793

Technical Committee 212 /

Comité technique 212

with granular material were fully saturated leading to extreme

softening (swelling) of the clay in the base of the excavations.

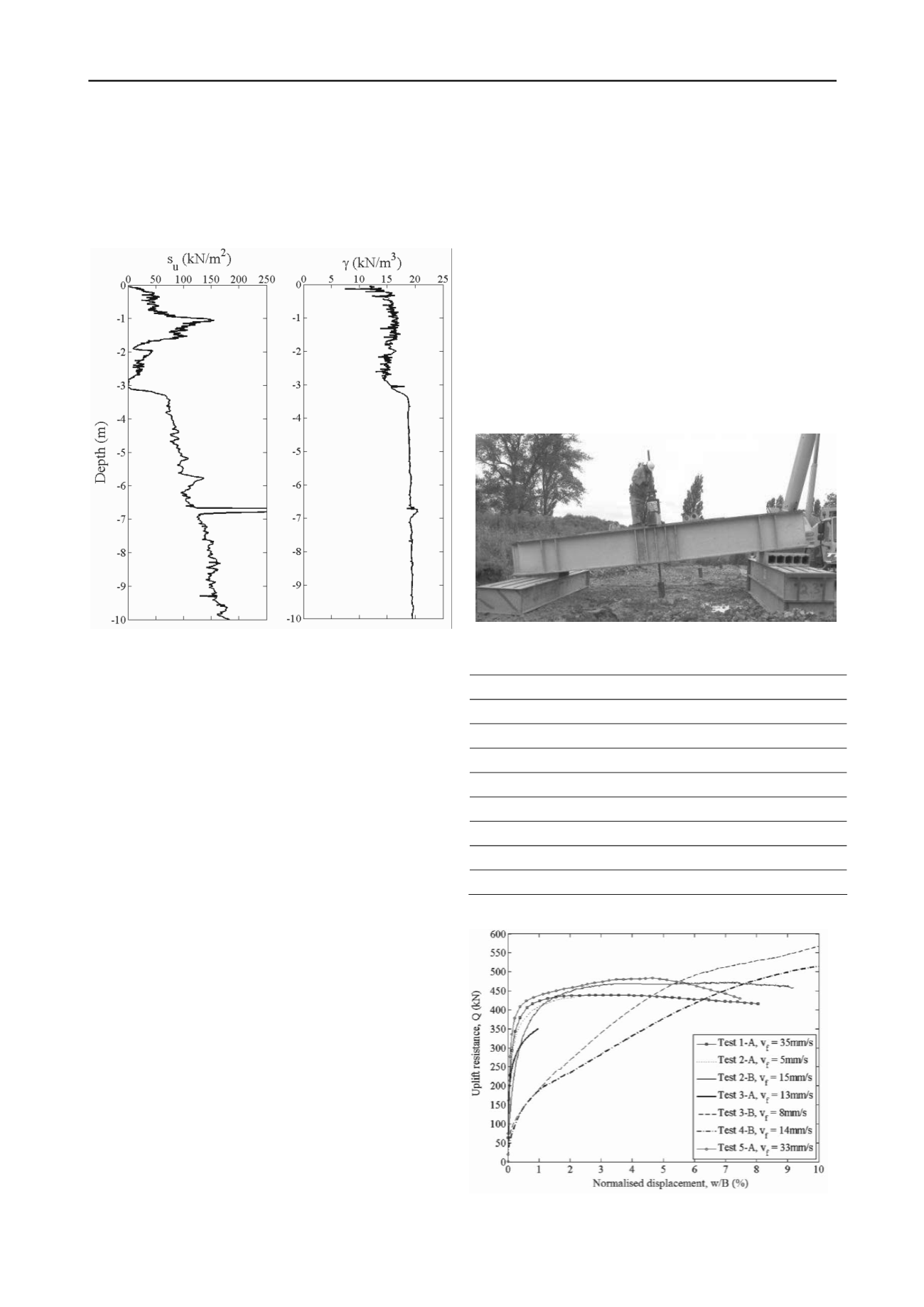

A total of five ~10m deep CPTs were used to characterise

the site and backfill. Using a N

kt

= 20 (Butcher et al. 2009) the

variation of s

u

and density (γ) of the London clay below 3m (the

founding plane) corroborates with previous observations. A

profile from Footing 5 is shown in Figure 2.

Figure 2. CPT profile of Footing 5

2.3

Load schedule

The footings tests were carried out over a period of six working

days (18

th

- 25

th

July 2012). Table 3.2 shows the order with

which the tests were carried out. The small displacement tests

(denoted ‘A’) of Footings 2 and 3 examined the rate effect at

small displacements in the fully bonded and breakaway

conditions. The first load test on Footing 4 was a design test to

BS EN61773:1997 (BSI 1997).

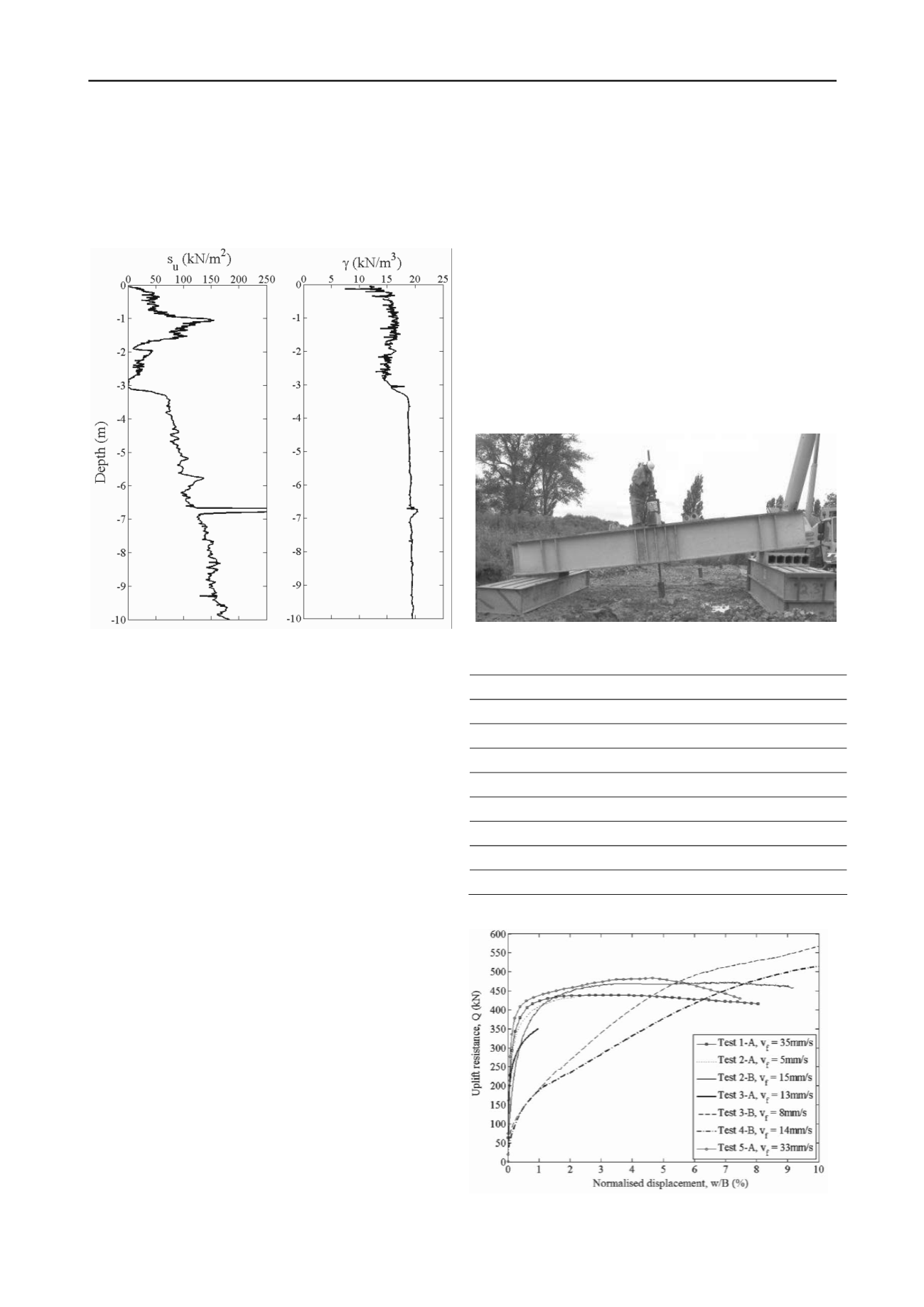

The load was applied to the footing stubs using a hydraulic

jack system. The setup of the reaction beams and jack is shown

in Figure 3. The reaction beams at the base were orientated

parallel to the line of the excavations and outside the failure

zone of a 30

o

frustum. The cross beams with the hydraulic jack

were inclined so that the footings could be pulled up in line with

the footing chimney. Wedges were placed under the cross beam

to achieve the required rake angles. The hydraulic ram had a

total stroke length of 150mm (w/B=10%).

The resistance of the footing during uplift was measured

using a load cell mounted above the hydraulic jack. The

displacement of the footing was measured by mounting LVDTs

on a reference beam. The LVDTs were vertically orientated and

recorded the movement from the head of the chimney. The data

from the instrumentation was acquired using a Campbell

CR5000 data logger sampling at 10-100s/s.

3 FIELD TEST RESULTS

3.1

Load-displacement behavior

The load-displacement profiles of the tests conducted with a

London clay base displayed an extremely stiff response (see

Test 1-A and 5-A.

The loading rates during the first few millimetres of

movement was in the range 276 kN/mm (Test 2-A) – 333

kN/mm (Test 1-A). The peak capacities of the footings were

achieved between w/B = 2.1 - 4.7% versus the secondary test

which were generally in excess of 7%. Although the Tests 1-A,

did not affect uplift capacity. The measured uplift capacities

were similar for both tests (<10% difference) during the first

10mm of uplift and at peak there is a difference of 50 kN versus

Test 1-A and 5-A.

Test 3-A was

2-A and 5-A were conducted at different uplift velocities this

used to examine the difference that base

co

gr

Ta 2. Load schedule

est

w (mm)

v

f

(mm/s)

ntact conditions at small displacements would have. Although

the test did not reach its peak the stiffness response is

comparable with Footing 2-A. This implies that the base

condition contribution was similar to the footings tested on

London clay and that the blinding did not fulfill its purpose of

excluding suctions from uplift i.e. acted a free draining material.

Tests 3-B and 4-B indicated that the performance of Type 2

anular fill is extremely poor and could only mobilise ~50% of

Q

des

at w=10mm. Large displacements were required for the

granular fill to mobilise sufficient strength to produce uplift

capacities equivalent to Q

des

(w = 60mm Test 3-B and w =

80mm Test 4-B). It should be noted on Test 5-A reached Q

des

within a 10mm displacement.

Figure 3. Field test arrangement

ble

Footing

T

1

1-A

150

35

2

2-A

15

5

2

2-B

150

15

3

3-A

15

15

3

3-B

150

10

4

4-A

BS EN61773:1997

4

4-B

150

15

5

5-A

150

35

Figure 4. Load-displacement results for rapid uplift footings