2784

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

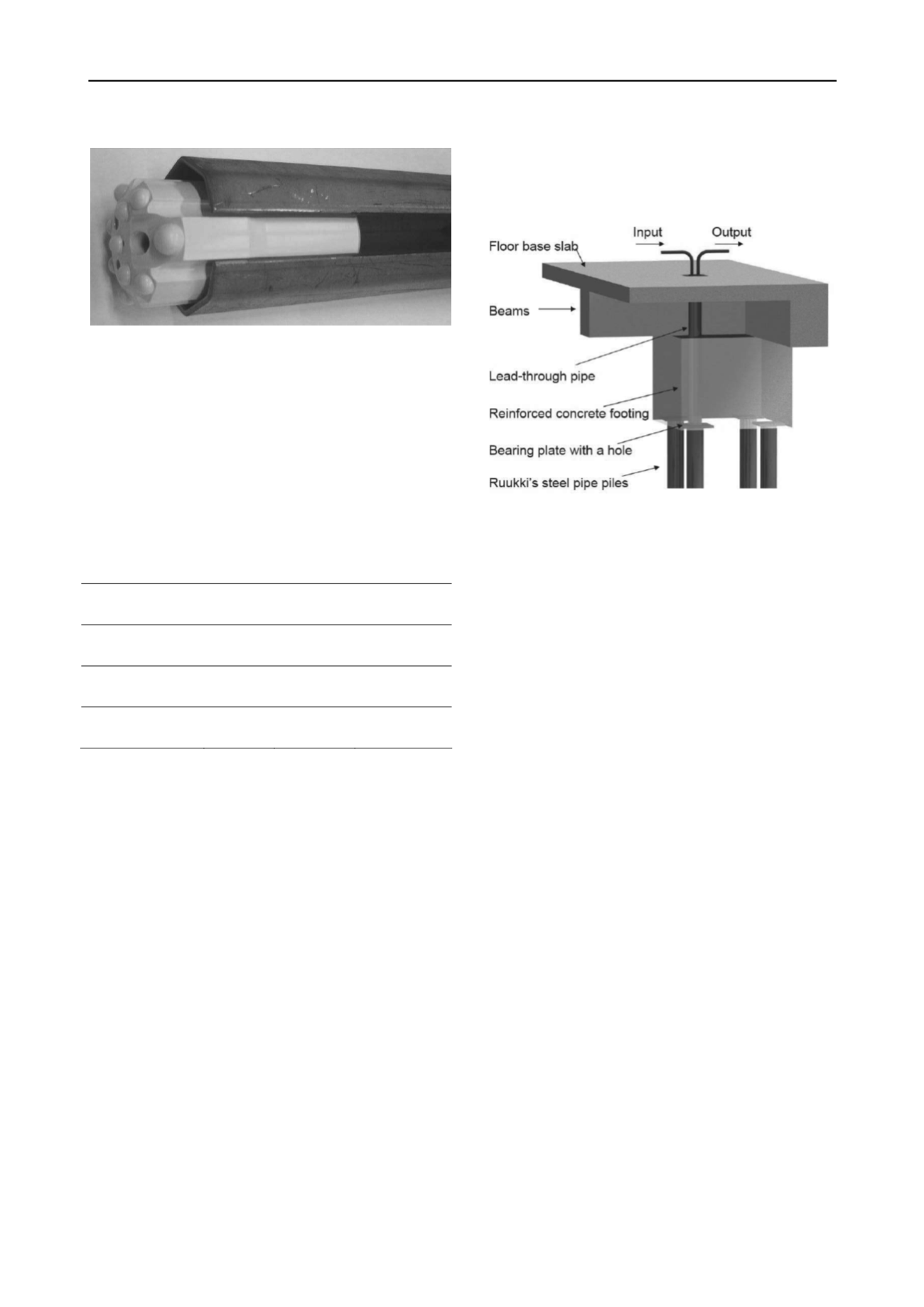

Figure 2. Drilling of an open C section can be done using an eccentric

drilling bit.

A new invention has been introduced in Finland to drill an

open section as a structural body of a drilled pile. Open section

drilling can be done using an eccentric drilling bit (Fig. 2) and

the eccentric part of the machinery can be removed from the

pile body through the open side of the steel section. The

drilling bit has been developed by Robit Rocktools Ltd and the

C section has been developed by Emeca Oy. Drilling has been

tested (Table 1) until now using the top hammer method but the

DTH drilling could be applicable, too.

Table 1. Test sites for open section drilling in Finland.

Site

Soil

layers

Pile

diameter

Lengthening

coupler

Masku 2010

gravel,

bedrock

80 mm

no

Espoo 2011

gravel,

clay

80 mm

no

Naantali 2012

clay,

moraine

80 mm

yes

3 ENERGY PILES

The use of energy piles has grown since 1980s when concrete

piles were started to utilize to transfer heating or cooling

energy. When the end bearing steel pipe piles have become

very common in the Nordic countries, development of energy

type micropiles has been an interesting opportunity to face

demand of greener energy and lower energy consumption.

(Uotinen et al 2012)

3.1

Steel pipe piles

The pipe piles are easy applicable to use as energy piles due to

hollow structure of the pile. Steel material has a good thermal

conductivity reducing the thermal resistance of the energy pile.

Steel pipe piles can be installed by driving, drilling, jacking or

vibrating. The minimum outer pile diameter considering the

heat collecting pipes is 88,9 mm but typically diameter for

drilled energy piles is close to 200 mm or more.

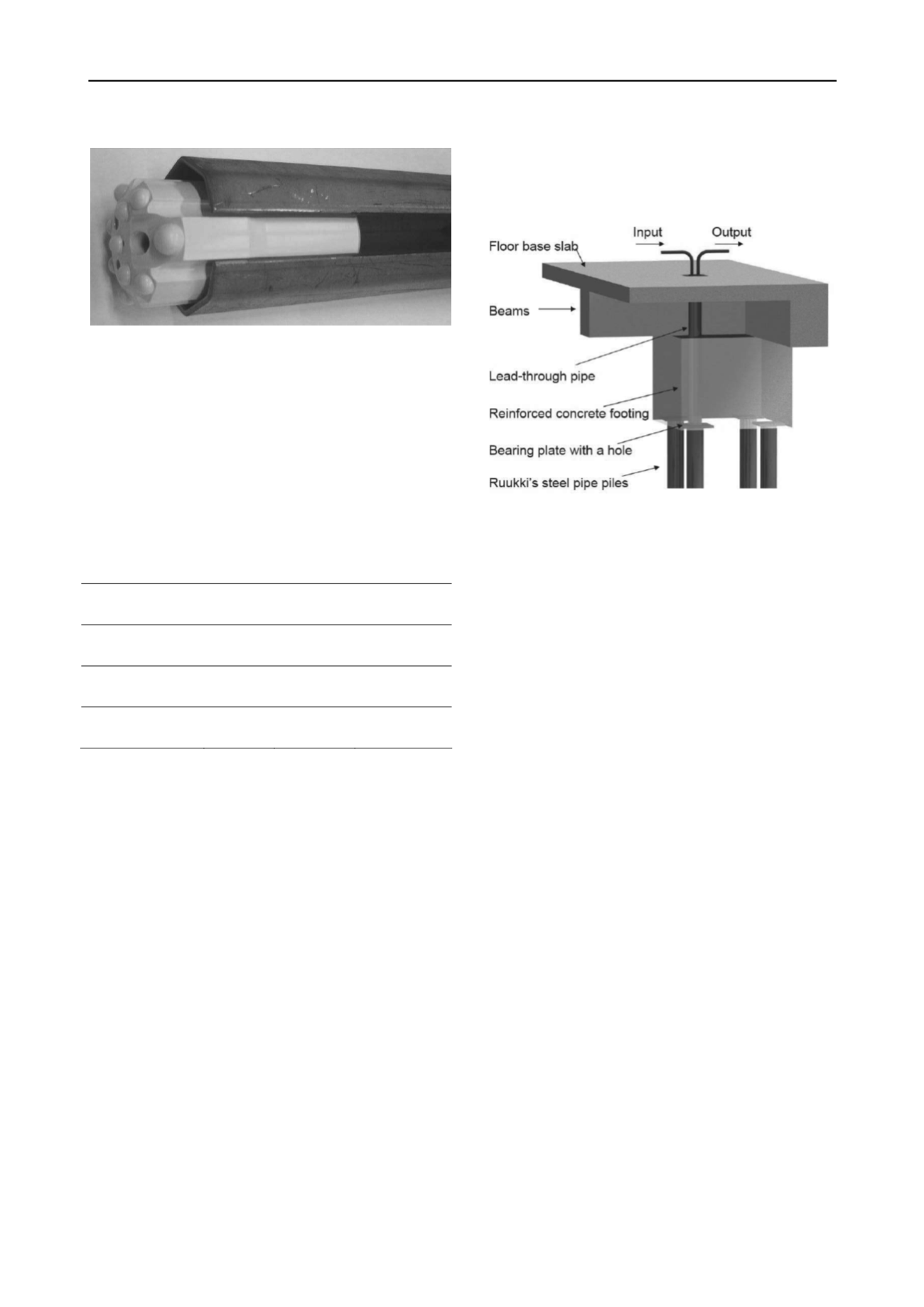

3.2

Heat collecting components

Normally, the heat collecting pipes are made from high density

polyethene, diameter between 20 to 40 mm. One or two U

loops of collecting systems (Fig. 3) are installed inside of a steel

pipe pile. Water-ethanol mixture is the most common liquid

used in energy piles. (Uotinen et al 2012)

3.3

Case study: an office building in Finland

The first energy pile building in Finland was constructed to

Jyväskylä. The 6-storey office building, base area ca. 1700 m

2

,

Figure 3. Loops of energy collecting components are installed inside of

a steel pipe pile.

is equipped with 38 energy piles when totally 246 piles of 22 to

29 m length has been driven to fill, clay, silt and moraine

layers.The piles are type RR170/10, RR220/10 and RR220/12,5,

the pile load respectively 691 kN to 1350 kN. In addition, there

are 65 precast concrete piles; all piles were driven with Junttan

PM 20 LC piling rig and with 4 ton hydraulic hammer. The

space between the energy piles varies from 5,5 m to 7,8 m.

(Uotinen et al 2012)

4 DRILLED PILE WALLS

Drilled piles have been used for retaining walls have been

constructed in Finland, Sweden and Norway since 2008.

(Uotinen and Jokiniemi 2012) Drilled pile walls can be used in

demanding soil conditions where installation of conventional

sheet piles can face penetration problems or vibration risks. In

Northern Scandinavia and Finland, hard and large boulders are

common obstacles in the overburden limiting use of

conventional sheet pile and retaining wall methods.

Two variations of drilled pile walls have been introduced

based on either (i) Ruukki´s drilled steel pipe piles (RD piles) or

(ii) an application of open section drilling utilizing C and CT

profiles (Fig. 4). The RD pile wall cases are collected to Table 2

covering large variations of diameter and interlocking systems.

Totally 2150 piles or 24500 m piles have been used for drilled

RD walls until now.

The drilled pile walls can be used as a temporary or a

permanent structure. Typically, the wall has capacity to take

both high vertical and lateral loads when needed. (Uotinen &

Jokiniemi 2012)

5 CONCLUSION

The market share of micropiles and other steel piles is

remarkably high in the Nordic countries, partly due to active

research and development during the past decades. There are

versatile collection of applications available and many e.g.

drilled pile techniques extend the use of piles to design

solutions which are totally new for piles. The energy piles and

the drilled pile walls have great potential for future ground

engineering. Further research and development efforts will be

needed to get all potential benefits linked to the inventions.