2776

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

When the reinforced concrete compression member (e.g.,

reinforced concrete pile) is wrapped with the fiber reinforced

plastic, the axial load carrying capacity of the pile is increased

due to the confinement provided by the fiber reinforced plastic.

Such an effort to develop efficient concrete Column wrapped

with FRP has been continued from the early of 20th century.

Hybrid FRP-concrete composite pile (HCFFP) is consisted

of pultruded FRP unit module, filament winding FRP which is

in the outside of mandrel composed of circular shaped assembly

of pultruded FRP unit modules, and concrete which is casted

inside of the circular tube shaped hybrid FRP circular tube as

shown in Figure 1. Therefore, pultruded FRP can increase the

flexural load carrying capacity, and the filament winding FRP

tube and concrete filled inside of it can increase the axial load

carrying capacity.

In this study, in order to use as the pile for foundation

construction, we estimated the structural performance of

HCFFP through the uniaxial compression tests. Mechanical

properties of the FRP material are investigated. Based on the

reviews of previous research results and the experimental

studies conducted in this study, equation for predicting the

ultimate axial compressive strength of the HCFFP is suggested.

1 HYBRID FRP-CONCRETE COMPOSITE

COMPRESSION MEMBER

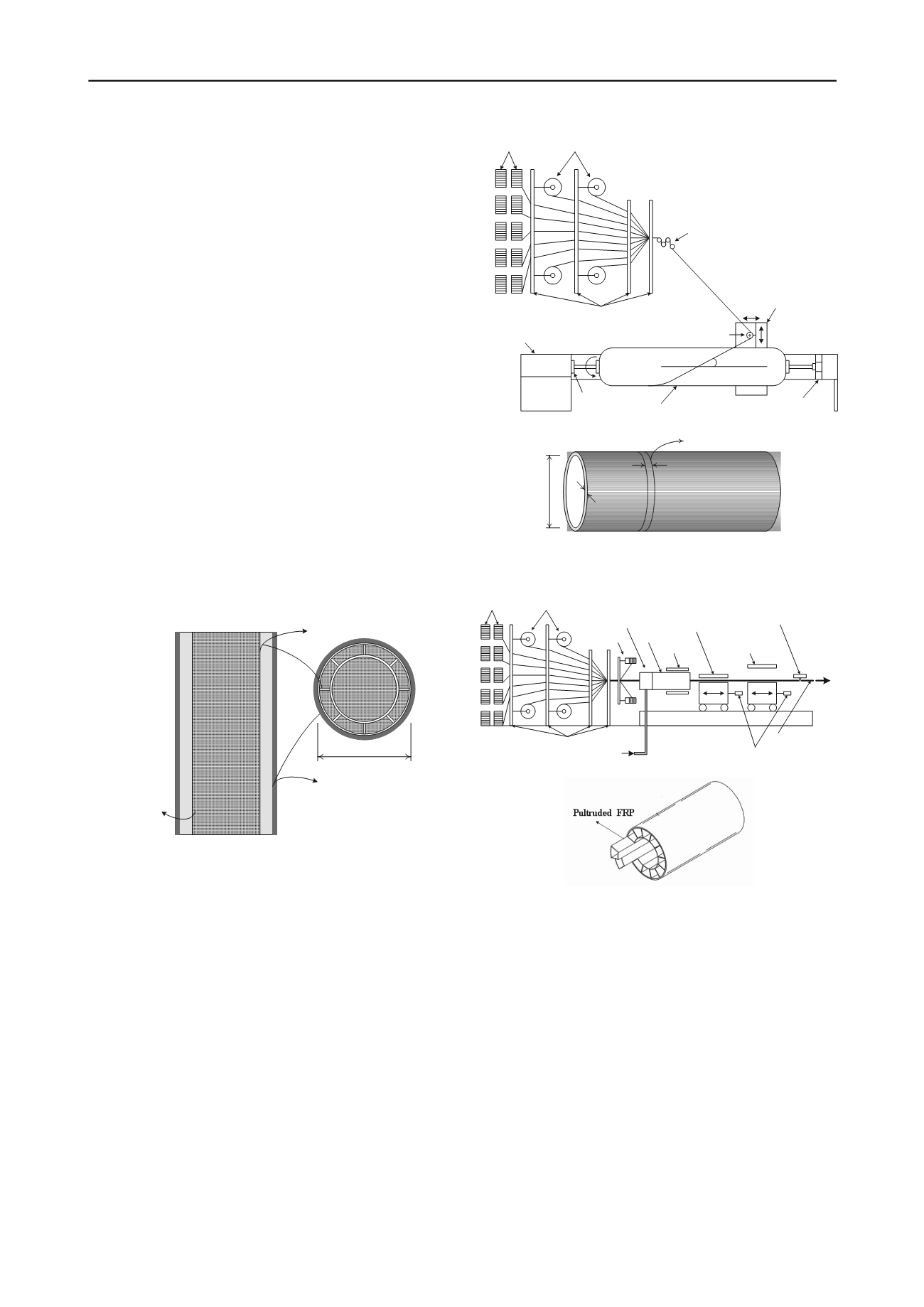

In this study, improved HCFFP system, an exterior filament

winding FRP layer component and an interior pultruded FRP

with concrete, is proposed as shown in Figure 1.

Pultruded

FRP

Concrete

Filament

Winding

FRP

D

Figure 1 Hybrid FRP-concrete composite pile (HCFFP).

The exterior layer consists of a multilayer filament winding

FRP. The interior reinforced concrete consists of pultruded FRP

and concrete. Filament winding FRP may have various cross-

sectional dimensions to satisfy the structural design

requirements. A cylindrical concrete core is located in the

filament winding FRP and pultruded FRP, where the interior

pultruded FRP and the exterior filament winding FRP provide

axial and circumferential reinforcement, respectively, for the

concrete core.

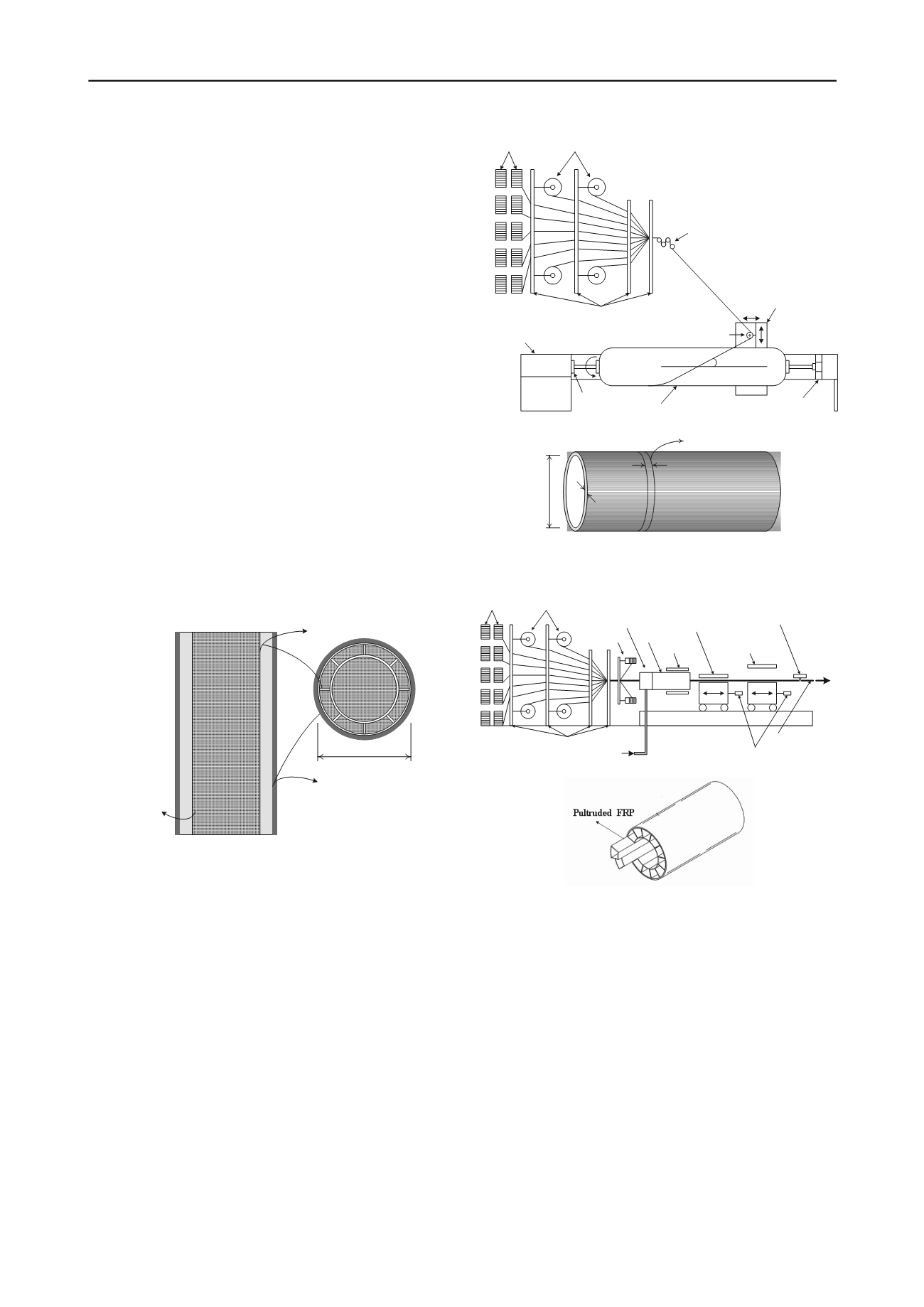

The specimens of HCFFP members, which are the FRP

circular tubes that had been manufactured by filament winding

and pultrusion processes are shown in Figures 2 and 3,

respectively. Filament winding process is surfaces of revolution,

such as pipes, cylinders, and spheres. In filament winding,

continuous reinforcements, such as roving, are wound onto a

mandrel until the surface is covered and the required thickness

is achieved. Pultrusion is a continuous manufacturing process

used to manufacture constant cross section shapes with

unlimited length. Pultrusion is a cost effective process because

it achieves direct conversion of continuous fibers and resin into

a finished part. The fibers are continuously impregnated and

pulled through a heated die, where they are shaped and cured.

Creel Racks Tape Racks

Preforming Guides

Spindle

Headstock

Mandrel

Tailstock

Horiz. &Vert. Carriage

Delivery Eye

Tensioning Device

a

d

t

frp

b

frp

Cutting

Figure 2 Manufacture of the filament winding FRP specimen.

Creel

Racks

Mat

Racks

Preforming Guides

Resin Injection

Winder

Injection

Chamber

Die

Heaters

Puller

Engaged

Puller

Design Gage

Moving Cutoff Saw

Hydraulic Rams

Finished Product

Figure 3 Manufacture of the pultruded FRP specimen.

2 LABORATORY TEST RESULTS

2.1

Mechanical Properties of Materials

Dimension of the filament winding FRP tube and pultruded

FRP specimens are given in Table 1. A glass-fiber and a

polyester resin were used to manufacture the FRP. Compressive

strength of concrete was obtained from the uniaxial

compression tests at the age of 28 days. Material properties tests

of the filament winding FRP tube were split disk and

compressive tests and pultruded FRP were tensile test. The split

disk test of the FRP specimens was carried out at the Structures

Laboratory in Hongik University, Korea. A total of 9 specimens

were tested for the split disk test and the compressive test,

respectively. A total of 9 specimens are tested, 3 for 3 tests, as

given in Table 1.

The failure load, the ultimate strength, and the modulus of

elasticity are determined and summarized as shown in Table 2,