2772

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

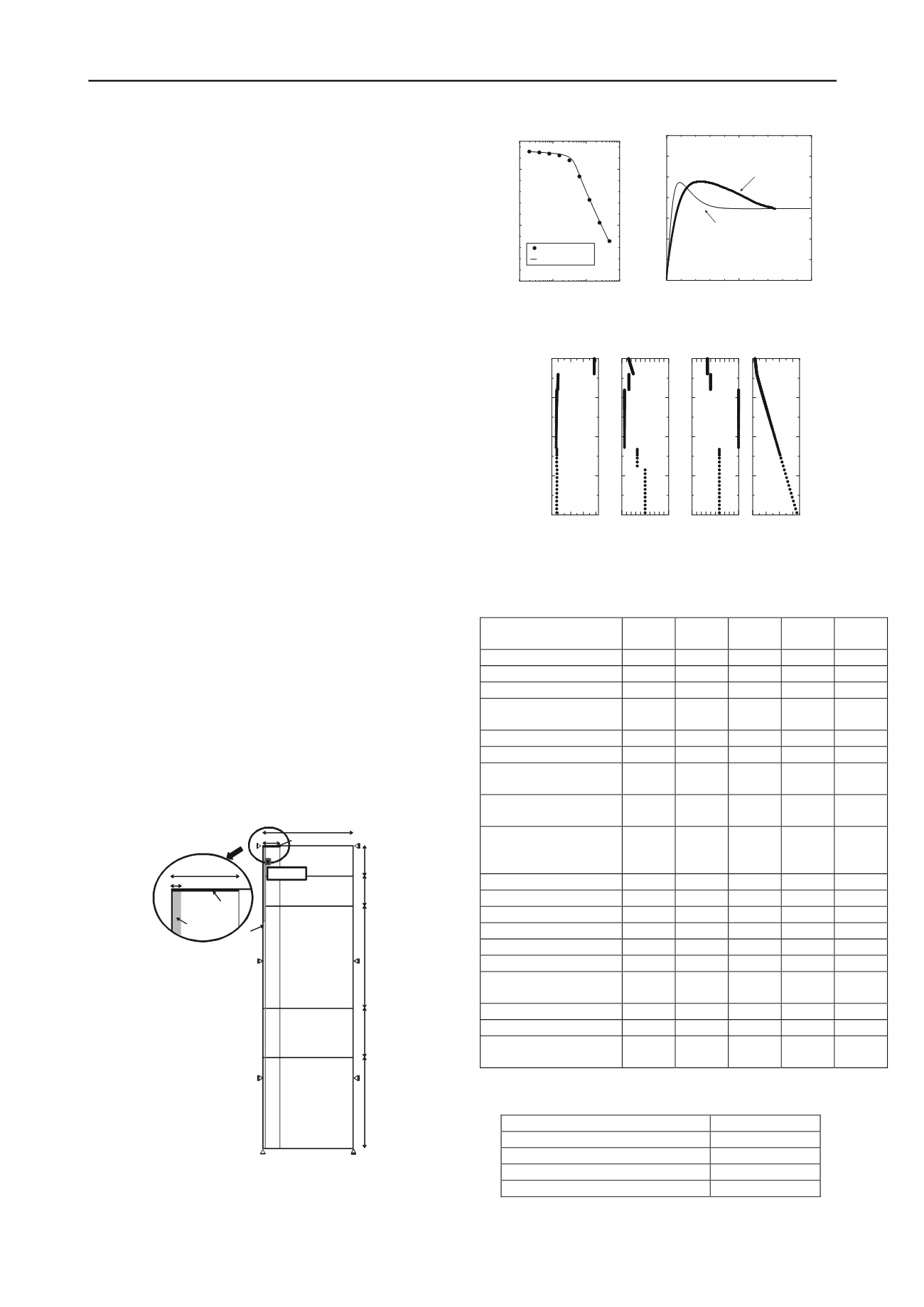

Although a full three dimensional (3D) analysis is preferable

when studying problems involving piles, in the present study a

two dimensional (2D) approach under axisymmetric conditions

was used in order to reduce the computation time. This means

that, even though the real raft shape was rectangular, a circular

raft was simulated. The raft had a radius of 2.257 m, giving it

the same area as the real raft. The pile had a radius of 600 mm

and was straight, with no base enlargement. From the top

surface, the simulated soil layers were clay 1 (4 m), sand 1 (4

m), sand 2 (13.5 m), clay 2 (6.5 m) and clay 3 (12 m), as shown

in figure 2. The material parameters were determined by

consolidation testing of clay 1 and drained triaxial compression

testing of sand 2. Figures 3a (clay) and 3b (sand) compare the

simulated and laboratory test results. For clay, the simulated and

experimental results agree well, but for sand, the initial

simulated modulus differs from the experimental data. This is

because the parameters of the simulated sand were chosen to

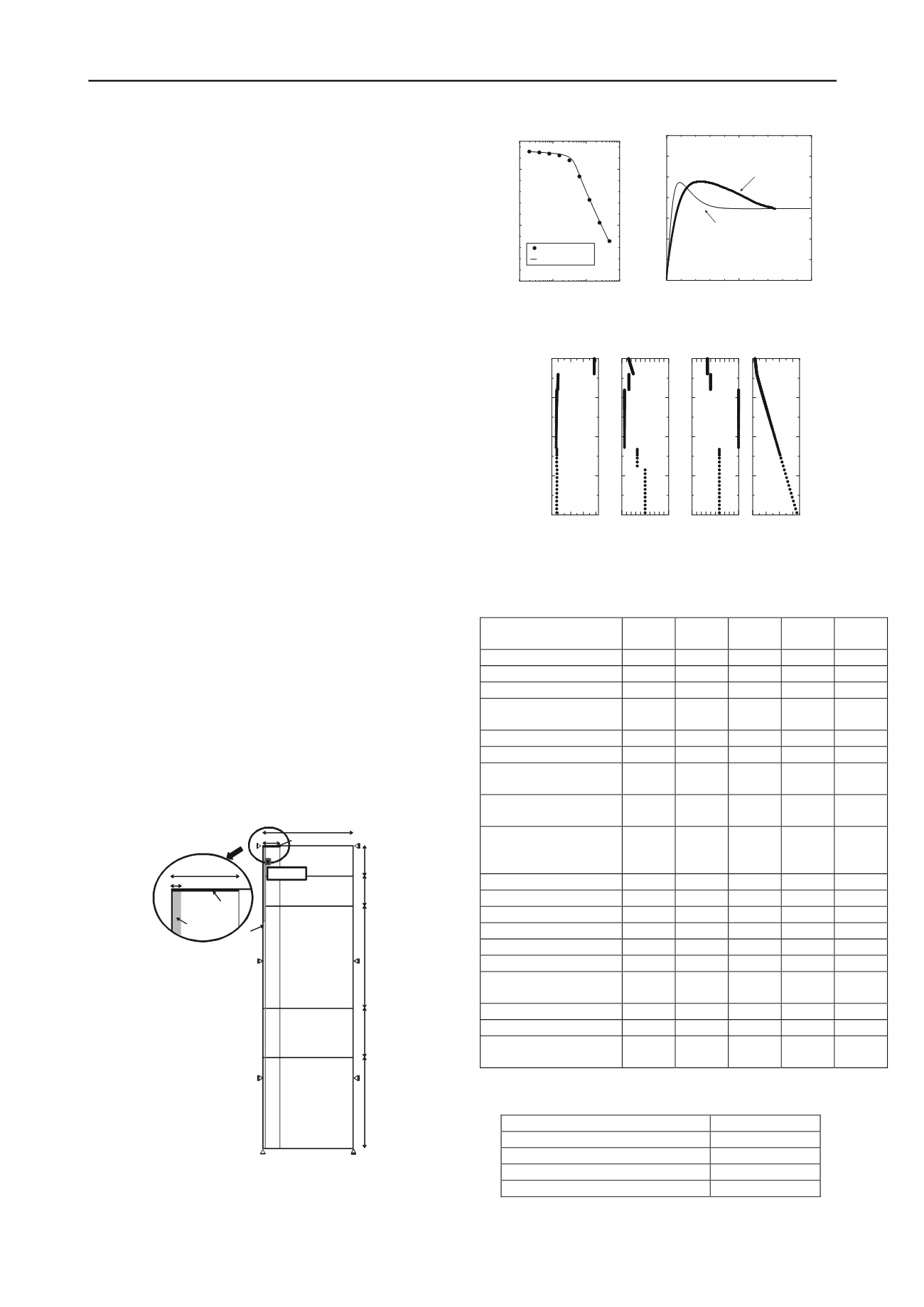

allow later simulation of a loading experiment. Table 1 shows

the soil material parameters. Due to the lack of experimental

data, some of the material parameters for clays 2 and 3 were set

to be the same as those for clay 1, but with different initial void

ratios. Similarly, some of the material parameters for sand 2

were set to be the same as those for sand 1. Table 2 shows the

pile material properties, which correspond to the typical linear

elastic parameters of pre-stressed high-strength concrete. Figure

4 shows the initial simulated soil profile. A load of 19.2 kPa

was applied to the soil surface at the raft position to simulate the

load of the raft. Displacement of raft elements in the x direction

was restrained, but displacement in the y direction was allowed.

The stratified soil model was first prepared, after which

elements with properties corresponding to the pile material were

added. This was done while taking into account the force

equilibrium between the soil and pile elements. After the excess

pore pressure dissipated, a vertical displacement was applied to

the pile elements for the three different cases: Case 1 models the

raft alone, Case 2 models the pile alone, and Case 3 models the

piled raft foundation. Figure 5 shows the step loading process

followed during the actual physical experiment. The bearing

capacity is dependent on the loading speed as well as the load

magnitude. In the simulation, even though cyclic loading was

not taken into consideration, the loading rate was set to a fixed

value of 0.01 mm/sec in consideration of the final 10 cm

settlement (Kaneda

et al.

(2012)).

4m

4m

13.5m

6.5m

12m

clay1

sand1

sand2

clay2

clay3

11.9m

2.257m

0.3m

2.257m

pile

pile

raft

raft

Aelement

Figure 2: Boundary conditions

10

1

10

2

10

3

10

4

1

2

3

Vertical Pressure (kPa)

Void Ratio

Experimantal data

Simulation

10

20

0

200

400

600

Axial strain (

%

)

Deviator stress (kPa)

Experimental data

Simulation

(a) Clay 1 (b) Sand 2

Figure 3: Experimental and simulation results

1 2 3 4

0

20

40

0 0.5 1 0 0.5 1

0 100200300

Void ratio

e

R

(=1/O.C.R.) State of structure

Height (m)

Vertical Stress

R

*

σ

v

(kPa)

Figure 4: Initial soil conditions

Table 1: Material properties of soils

<Elasto-plastic

parameter>

Clay 1

Sand 1

Sand 2

Clay 2

Clay 3

Compression index λ

0.50

0.050

0.050

0.10

0.10

Swelling index κ

0.02

0.012

0.012

0.015

0.015

Critical state constant M

1.45

1.36

1.36

1.26

1.26

NCL intercept N

(at

p

’ = 98 kPa)

4.3

1.98

1.98

2.00

2.00

Poisson’s ratio ν

0.1

0.1

0.1

0.3

0.3

<Evolution parameters>

Degradation parameter

of structure

a

0.8

2.2

2.2

0.8

0.8

Degradation parameter

of structures

b

and

c

1.0

2.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Degradation parameter

of overconsolidated state

m

5.0

1.0

1.0

1.2

1.2

Evolution parameter

b

r

0.001

1.00

1.00

0.150

0.150

Limit of rotation

m

b

1.0

0.6

0.6

1.0

1.0

Permeability

k

(cm/sec)

1.0

-7

4.0

-3

4.0

-3

1.0

-7

1.0

-7

Density ρ

s

(g/cm

3

)

2.631

2.631

2.631

2.65

2.65

<Initial conditions>

Void ratio

e

3.87

Overconsolidation ratio

1/

R

0

6.5

17.0

3.0

2.0

Degree of structure 1/

R

*

0

3.0

2.5

1.0

1.7

1.7

Degree of anisotropy ζ

0

0.545

0.545

0.75

0.545

0.545

Coefficient of lateral

pressure

K

0

0.6

0.6

0.5

0.6

0.6

Table 2: Pile material properties

Pile

Elastic modulus E (kPa)

47360000

Poisson’s ratio ν

0.2

Density ρ (g/cm

3

)

2.3

Coefficient of lateral pressure

K

0

0.0